Leaderboard

Popular Content

Showing content with the highest reputation since 07/27/2015 in all areas

-

0-30V 0-3A Latest Data

AsSa and 3 others reacted to repairman2be for a topic

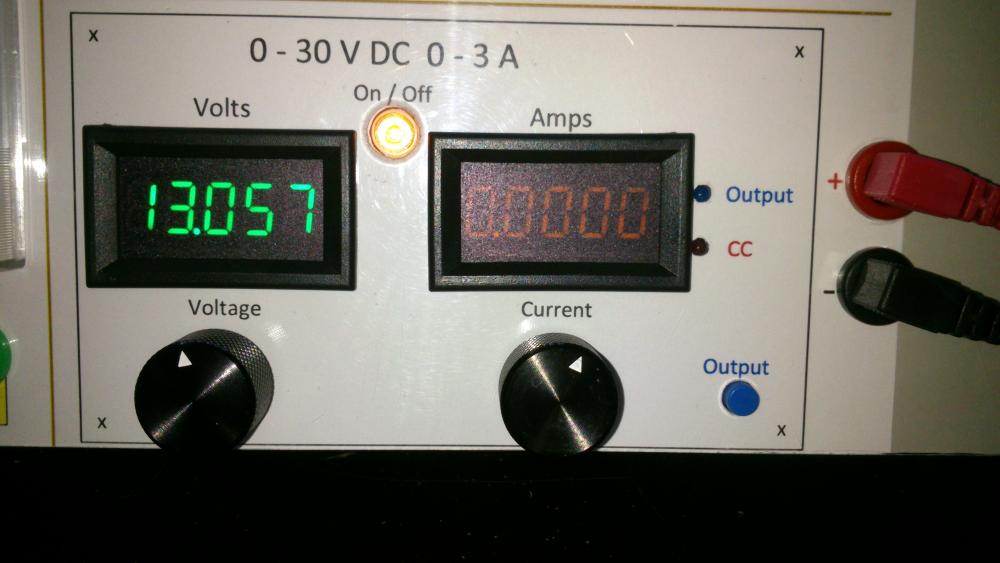

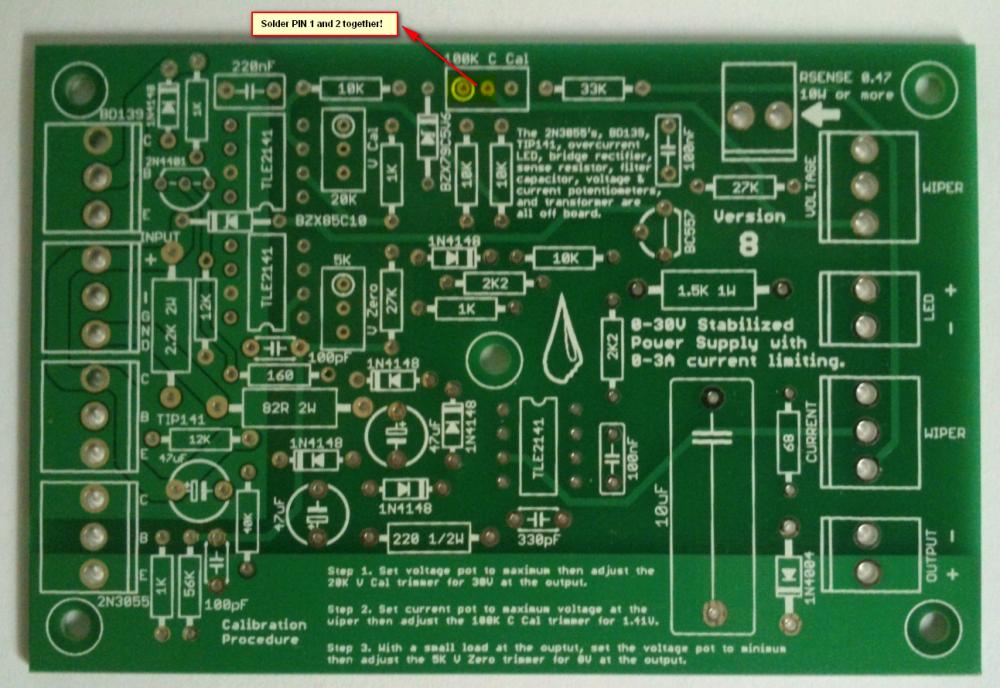

Hi all, Finally after some months have gone by, my build of the Power Supply is done. I have used liquibyte schematic Rev. 8 and had made the cirquit board according to the Gerber.zip file he posted here: 0-30V Stabilized Power Supply Page 88 posted October 6, 2014 "http://electronics-lab.com/community/index.php?/topic/29563-0-30v-stabilized-power-supply/&page=88" I left out D10 and R15 as per his description. I have plenty of boards leftover if someone has a need for it. There was only one mistake liquibyte made which have outlined in one of the pictures uploaded here. I was fortunate enough to get a big case with a Toroidal transformer from the scrapyard. Also many parts are recycled from various sources. Regards, William4 points -

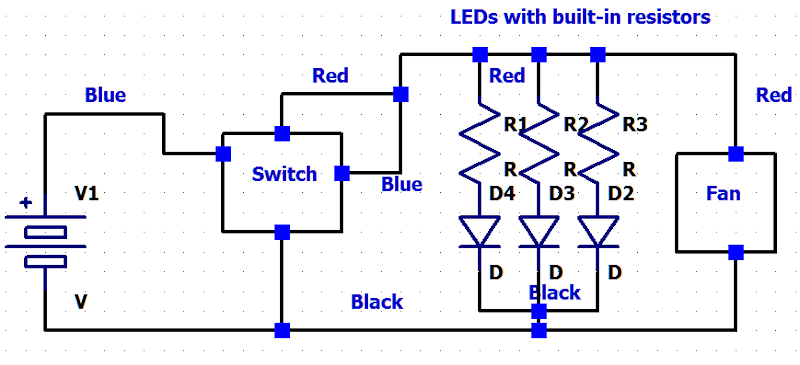

Finally, my post with the Eagle .sch and .brd, full gerbers, and parts list for Digikey in a zip file. I'm also including many of the pics I took as I was building that were posted both before and after this post. I'm still not completely done and may add more pics later. One thing I have changed is the third transformer for the auxiliary circuitry for the temperature sensor and fans and the displays (I wanted a better transformer than the Radio Shack special I had on hand). Archive attached. 30V.zip3 points

-

Solar-powered Bee Hotel w/ Particle Argon (ongoing project)

Jolin He and one other reacted to JamesMVictoria for a topic

Nice one, I like it.2 points -

How to easily turn on/off all debug message on Arduino IDE

SharonWatkins and one other reacted to MrNams for a topic

But even if we disable debug, it will call print method and do not print anything. I mean we should make it something like #ifdef DEBUG Serial.print("\n debug controlled print"); #endif Here when we disable macro, its like code is not written for compiler, code will be removed in macro processing itself.2 points -

H Bridge PWM DC Motor Driver + PCB

senaka ranathunga and one other reacted to sam.moshiri for a topic

An H-Bridge (Full-Bridge) driver is quite popular in driving loads such as brushed DC motors and it is widely used in robotics and industry. The main advantages of using an H-Bridge driver are: high efficiency, rotation direction change, and braking the motor. In this article/video, I have introduced a complete H-Bridge DC motor driver using four IR3205 power MOSFETs and two IR2104 MOSFET drivers. Theoretically, the above-mentioned MOSFET can handle currents up to 80A, however, in practice we can expect to get currents up to 40A if the MOSFET temperature is kept as low as possible, using a big heatsink or even a fan. References Article: https://www.pcbway.com/blog/technology/Powerful_H_Bridge_DC_Motor_Driver.html [1]: IRF3205 Datasheet: http://www.irf.com/product-info/datasheets/data/irf3205.pdf [2]: IR2104 Datasheet: https://www.infineon.com/dgdl/Infineon-IR2104-DS-v01_00-EN.pdf?fileId=5546d462533600a4015355c7c1c31671 [3]: 1N5819 Datasheet: https://www.diodes.com/assets/Datasheets/ds23001.pdf [4]: IR2104 Schematic Symbol, PCB Footprint, 3D Model: https://componentsearchengine.com/part-view/IR2104PBF/Infineon [5]: IRF3205 Schematic Symbol, PCB Footprint, 3D Model: https://componentsearchengine.com/part-view/IRF3205ZPBF/Infineon [6]: CAD Plugins: https://www.samacsys.com/library-loader-help2 points -

Non Contact Hand Sanitizer Dispenser, Easy, Cheap, No Arduino!

sam.moshiri and one other reacted to admin for a topic

Thanks for sharing your project with us. Could you give more details on the control board?2 points -

The original circuit should work fine up to 15V at 1A if you replace the old opamps with the newer higher voltage ones. You probably should recalculate the resistors that set the maximum voltage and current outputs. If the Chinese kit uses the transistor that shorts the opamp output when the power is turned off then the resistors that feed the transistor need to be recalculated for the reduced voltage. I have used perforated stripboard for many projects including very complicated ones. The copper strips are cut to length with a drill-bit and become almost half the wiring of a pcb. The parts and a few short jumper wires become the remainder of the wiring. Only one wire is in each hole so changing a part is easy like on a pcb.2 points

-

Hi, as promised I made an English translation of my working. Maybe there is few mistakes and I am sorry for that ! Good reading. ExplicationEN.pdf2 points

-

I use copper wire, not rice wire. They put rice in everything they make, especially batteries.2 points

-

0-30 Vdc Stabilized Power Supply

electron234 and one other reacted to elctro123 for a topic

So Finally which version of schematic is correct / flawless to build the PSU ?2 points -

February 23 above on this page has the latest schematic of the revised 3A lab power supply.2 points

-

Does anyone has LM3914 pspice library? i desperately need it..pleeeeease!2 points

-

Low power solenoid?

AmelieScott and one other gave a reaction for a topic

I want to apply force for an extended amount of time (10 secs to a couple minutes) using a solenoid actuator. Unfortunately, it seems that solenoids use a lot of power when they are active. Is there a solenoid type that will only use power when switching between active and not active? There's probably a way I can do this with an external mechanism, but I was wondering if there may be commercial solenoids that have this built-in. Thanks, Jessica2 points -

Illegal content (ebook/magazines/software) will be deleted without any notice. Thanks2 points

-

Overload Protector A16 ???

joeydennis11 and one other reacted to tjolle62 for a topic

In a few circuit diagrams i have they refer to a what seems to me is a transistor with B C E as a overload protector and with number A16 and i have looked for a few hours on the net and i can't find anything on this little fellow, Anyone knows what I'm looking for and wanna share that info Please .... Come on !! 48 visits !! some one must know what it is !!! PNP is it also...........2 points -

Overload Protector A16 ???

joeydennis11 and one other reacted to tjolle62 for a topic

At last i got a theori from a totally different place and he wasn't shure either but he had a weak memory that it could be 1A16 and a PNP transistor but after several deep searches on the I-net it didn't make any kind of senses whatsoever ???2 points -

Car battery to parallel port

tracythomas50 and one other reacted to MP for a topic

When you use your resistive divider to drop the voltage down to 5 volts, you just need to select values of resistors to limit the current. This is basic ohm's law. V/R. Was this your question or did I misunderstand? I am not sure how you intend to monitor status by using one 5 volt pin. As an interface to the parallel port, you could use an LM3914. This would give you the resolution you need. There are also many other ways to proceed. You need to convert from analog to digital to read anything useful from the parallel port. MP2 points -

Car battery to parallel port

tracythomas50 and one other reacted to Omni for a topic

Hi TJBraza, http://www.analog.com/UploadedFiles/Data_Sheets/ADT7485A.pdf Although, it will probably require a small program written in C or Visual basic to convert the string MSB & LSB into a more easier read etc... Take a moment and review the data sheet, the IC has a lot of potential.2 points -

SL100 & SK100 transistor

AmelieScott and one other reacted to alanng96 for a topic

I can't find SL100 & SK100 transistor :'( Which transistors can replace these? Thank you for your help~ ;)2 points -

Calm down people. It is not Mixos's fault, if it is against the law he has to remove the content. This site is very good for asking electronic related questions, I have yet to find a better one.2 points

-

1 point

-

Good to know that you got it working.1 point

-

How a Power Quality Meter works and why it is so Important

Bobfadi reacted to James Franklin for a topic

Well Power quality monitoring is important because it will help officials to understand about the quality, power of electricity for a safe regular process. It tells official about the electrical current flow and its quality. For more information visit our blog https://sfere-elec.net/products/Power-Quality-Monitoring-20.html1 point -

DIY - ARDUINO BASED CAR PARKING ASSISTANT

davidjackson reacted to Ashish Adhikari for a topic

Introduction ---------------- Hi Friends, I am back again with another Arduino based home automation project. This time I am trying to make my partner's life easy by installing a collision avoidance system in the garage to help her park the car safely without hitting the garage wall. So, in this video, I am going to use an ultrasonic sensor to calculate the car's distance from the garage wall and display it using green, yellow and red LEDs. The color of LEDs indicates whether to keep moving, slow down, stop or go back. The total cost of the project is around $20 - $25. Step 1: Logic The project has 3 phases Phase 1: Waiting for the car In this phase the device keeps looking for a moving object within the sensors proximity. If an object enters the proximity then one of the three LEDs turns on based on how far the moving object is. If the object is way too close, then a noise is made to make the moving object aware of the distance. Phase 2: No car in the garage If there is no object in the proximity then turn off all the LEDs. Phase 3: The car has stopped moving (Parked in the right spot) If the object has stopped moving and is still in the proximity wait for 20 CPU cycles and then turn off the LEDs. Step 2: Hardware Requirement For this very simple project we need: - A Perfboard - An Arduino nano/uno (whatever is handy) - A Red, Green and a Yellow LED (Light Emitting Diode) - 3 x 220ohm resistor for the LEDs - One HC-SRO4 Ultrasonic Sensor - A Buzzer shield or A buzzer and a 100 ohm resistor - A 220v AC to 5v DC Buck step-down module - One Female Pin Header Strip - An Ethernet cable - Some connecting cables - A USB cable to upload the code to the Arduino - and general soldering equipments Step 3: Assembly Let start by connecting the LEDs to the board. Connect the Red LED to pin D2, Yellow LED to D3 and the Green LED to D4 of the Arduino by putting in a 220ohm resistor between the Arduino board and the LEDs. Now lets connect the Buzzer to analogue pin A0. Next, connect the Trig pin of the Ultrasonic Sensor to D5 and the Echo pin to D6 of the Arduino. Once all the modules are connected to the Arduino board, its time for us to connect all the positive and negative pins together. Connect all the positive pins of the modules to the +5v supplied by the Buck Step-Down Module and the negative pins to the -ve terminal of the Module. That's it, we can now upload our sketch to the board. In this assembly I am using 3 LEDs to display the distance, however you can replace the 3 LEDs with a RGB LED, or you can also use an array of LEDs like an audio level indicator to display the movement of the car. Step 4: My Setup OK now lets see what I have made. I have installed the Arduino, buzzer, the ultrasonic sensor and the three 220 ohms resistors on one Perfboard. The 3 LEDs and the power module is installed on a second Perfboard. I will be covering the LEDs with a translucent cover to give it a nice look. The 220v power supply will be connected to the screw terminal block. The base unit will then be connected to the LEDs and the power supply with an Ethernet cable. Step 5: The Code int trigPin = PD5; // Sensor Trip pin connected to Arduino pin D5 int echoPin = PD6; // Sensor Echo pin connected to Arduino pin D6 int redLED = PD2; // Red LED connected to pin D2 int yellowLED = PD3; // Yellow LED connected to pin D3 int greenLED = PD4; // Green LED connected to pin D4 int buzzer = A0; // Buzzer connected to Analogue pin A0 long TempDistance = 0; // A variable to store the temporary distance int counter = 0; // Counter value to check if the object has stopped moving void setup() { Serial.begin(9600); pinMode(trigPin, OUTPUT); pinMode(echoPin, INPUT); pinMode(redLED, OUTPUT); pinMode(greenLED, OUTPUT); pinMode(yellowLED, OUTPUT); pinMode(buzzer, OUTPUT); } void loop() { long duration, Distance; digitalWrite(trigPin, LOW); delayMicroseconds(2); digitalWrite(trigPin, HIGH); delayMicroseconds(10); digitalWrite(trigPin, LOW); duration = pulseIn(echoPin, HIGH); Distance = (duration/2) / 74; // Distance in Inches if(counter < 20){ // Do the rest if the car is still moving if (Distance > 200) { // Nothing in the garrage turnThemAllOff(); } if ((Distance > 55) && (Distance <= 200)) { // Turn on Green LED digitalWrite(greenLED, HIGH); digitalWrite(yellowLED, LOW); digitalWrite(redLED, LOW); noTone(buzzer); } if ((Distance > 15) && (Distance <= 55)) { // Turn on Yellow LED digitalWrite(yellowLED, HIGH); digitalWrite(redLED, LOW); digitalWrite(greenLED,LOW); noTone(buzzer); } if (Distance <= 15) { // Turn on Red LED digitalWrite(redLED, HIGH); digitalWrite(greenLED,LOW); digitalWrite(yellowLED, LOW); noTone(buzzer); } if (Distance < 8) { // Item is way to close - start the buzzer tone(buzzer, 500); } } if ((Distance == TempDistance) || ((Distance+1) == TempDistance) || ((Distance-1) == TempDistance)){ if(counter >= 20){ // Turn off the lights if the object hasn't moved for 20 cycles (no change in distance) Serial.println("No movement detected, turning off the lights"); turnThemAllOff(); } else { counter++; } } else { counter = 0; // Reset counter if there is a movement } TempDistance = Distance; Serial.print(Distance); Serial.println(" inches"); Serial.print("Counter : "); Serial.println(counter); delay(500); } // Function to turn the LEDs off void turnThemAllOff(){ digitalWrite(redLED, LOW); digitalWrite(greenLED,LOW); digitalWrite(yellowLED, LOW); noTone(buzzer); } Start the code by defining the constants and the global variables that will be used throughout the code. Then define the pin modes in the setup section of the code. Then create a function to turn off all the LEDs and the buzzer. Now, calculate the "Distance" in inches by reading the values received from the Ultrasonic Sensor. Then by checking the value of the "Distance" we will turn on and off the LEDs based on how far the object is. If the distance is greater than 200 then turn off all the LEDs and the buzzer as the object is out of range. Else if it is between 55 and 200 then turn on the green LED. If the object is between 15 and 55 then turn on the yellow LED, and if the object goes closer than 15 inches then turn on the red LED until it reaches 8 inches. When the distance becomes less than 8 start the buzzer along with the red LED. Next bit of the code is to set the value of the counter based on the cars movement which then decides when to turn off the LEDs. It compares the value of "Distance" with the "TempDistance" and if the values are same (object hasn't moved) then increments the counter. If the object moves any-time during this process the counter is reset to 0. Finally the "TempDistance" is set to the value of "Distance". Just before comparing the Distances we also need to check if the counter value has exceed 20. I am doing this to stop the below code from executing if the car is in a steady position. Lastly we just need to add a small delay to our sketch to pause the code for a while. Step 6: Quick Demo So this is how I have installed the unit in my garage. As I walk close to the sensor the light changes from green to yellow to red and ultimately the buzzer goes on when I am too close to the sensor. In my case I have installed the buzzer next to the Arduino however I will recommend you to install the buzzer along with the LEDs. If you want you can also flash the red LED when the buzzer goes on. So now, my partner can park the car easily without making any assumptions. Doesn't matter how many times she fail her driving test she is not going to break my wall (even when she is drunk). Not that I am asking her to drive when she is drunk (just kidding). Thanks again for watching this video! I hope it helps you. If you want to support me, you can subscribe to my channel and watch my other videos. Thanks, ca again in my next video.1 point -

Tablet charging IC replacement

Vasant Seechurn reacted to HarryA for a topic

Do you think it is a D6Gi1K or D6GiLK ? After the G it looks like an aye i gather. Not even close: http://twitpic.com/d6gilk SOT323 is a SMD package type; it has only three leads. Often a transistor.1 point -

Touchless Covid Free Electronic Dice Using Arduino

Ashish Adhikari reacted to charlesmox1 for a topic

I'm looking forward to the next post)Keep it up!1 point -

Good book for beginners?

KaneD reacted to charlesmox1 for a topic

By the way, thanks for the books, Perhaps someone can advise something relevant today?1 point -

Question electrolytic capacitor

17669 reacted to nogueiraat for a topic

my room the temperature varies 31-33º the humidity varies 55-70% this epcos information valid for other electrolytic capacitor manufacturers? in the 1990s were electrolytic capacitors or another type of capacitor used?1 point -

from Wikipedia: = (K+L)(K+M)(L+N)(M+P)(N+Q)(P+Q) = (K+LM)(N+LQ)(P+MQ) = (KN+KLQ+LMN+LMQ)(P+MQ) = KNP + KLPQ + LMNP + LMPQ + KMNQ + KLMQ + LMNQ + LMQ ----------------------------------------------------------------------------------------- K * N+LQ + LM*(N+LQ) K * N+LQ = KN+KLQ and LM*(N+LQ) = LMN+LMQ for the : (KN+KLQ+LMN+LMQ) for the fourth line multiply the third line by P and then by MQ from (P+MQ)1 point

-

The 24VAC transformer probably produces 25VAC with a light load on the project. Then its rectified and filtered output is +34V and -5.6V which power the opamps. At times the voltages are higher. Your transformer will be overloaded if its power rating is 105VA or less (24V at 4.4A).. The old TL081 opamps have an absolute maximum allowed supply of a total of only 36V so they will not last long. Replace the opamps with TLE2141 opamps that have a maximum allowed supply of 44V. Many of the resistors and the driver transistor in the original project are overloaded. Upgrade them. The main filter capacitor C1 value is much too low, upgrade it.1 point

-

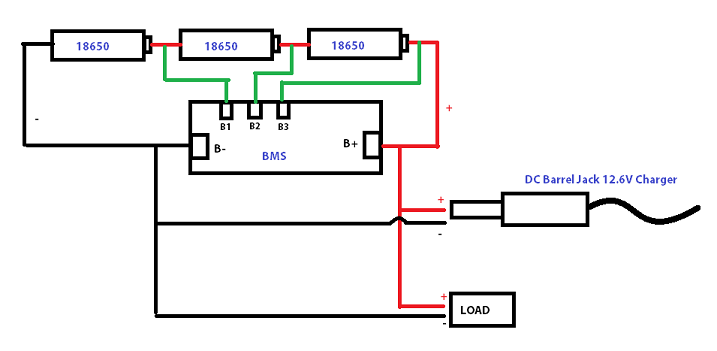

BMS Charger for 18650

gztoppower reacted to admin for a topic

1 point -

Need Help: Bluetooth External Camera controlled by iPhone app

aleksczajka reacted to HarryA for a topic

Perhaps? To big? " This Fujifilm FinePix digital camera has Bluetooth connectivity for wireless media transfer. " https://www.bestbuy.com/site/fujifilm-finepix-xp130-16-4-megapixel-digital-camera-sky-blue/6204739.p?skuId=62047391 point -

The original project used a 24VAC transformer and TL081 opamps that have a maximum allowed supply of 36V. Since the project was not able to produce 30VDC at 3A because the supply voltage was too low, I changed the transformer to 28VAC and changed the opamps to TLE2141 that have a maximum allowed supply of 44VDC. Please post a video of your TLE2141 opamps blowing up if you power them from the 66VDC produced from rectifying the 48VAC from your wrong transformer. Or just parallel the two 24VAC secondaries which produces a rectified 32VDC so that the maximum regulated output from the project will be about 25VDC at 3A. The TLE2141 U2 gets warm, not hot because its output current is fairly low since it drives the driver transistor Q2 that drives the output transistors to 3A.1 point

-

PCBWay vs OSH Park vs Smart Prototyping

davidjackson reacted to Soldertraining for a topic

In PCBWay, the boards are good quality and pricing is great while OSH Park is an aggregator. They collect your board files and panelize them with others to get a good price. And in case of Smart-Prototyping, especially their PCBA services. Their service is very affordable.1 point -

A modern day 0 - 30V, 0 - 3A Linear Power Supply?

navidmomeni reacted to admin for a topic

You may check this blog for a revised version of the popular 0-30V PSU: http://www.paulvdiyblogs.net/2015/05/tuning-030v-dc-with-03a-psu-diy-kit.html1 point -

Drill a hole on top of the mailbox and insert a ----> Without its pole. Optional, add a door switch for the LED. Done fast for $1. Some silicone sealant may help.1 point

-

Thanks for the freelancing job recommendation but I am a 70 years old government worker (I am retired with a government pension and some stocks and bonds) so I do not need more income. I do whatever I want whenever I want.1 point

-

I don't know about function but it certainly seems like it's trying to look like it. I get why he wants everything integrated and looking the same but I despise the web 2.0 look. The first person to do this was doing something unique, everyone else, not so much.1 point

-

Arklite take a look at this PS output at start up using current control.1 point

-

All that means is that if the capacitor is too small, it won't be large enough to damp the oscillations but if it's a single, large value capacitor it won't be good either. Higher value capacitors tend to have poor high frequency characteristics and become inductive past the resonant frequency, the higher the value, the lower the resonant frequency. Rather than using a single, high value capacitor, it's better to use a large capacitor and lower value capacitor in parallel with one another. The type of capacitor is also important; for example tantalum is better than electrolytic. I'd recommend a 1uF tantalum in parallel with a 100nF and 10nF ceramic capacitor on both the input and output. If you don't have a 1uf tantalum, go with 22uF electrolytic.1 point

-

2n2222 resistor value

Sidney Bell reacted to eplanet for a topic

thanks hero999 is there any formula for this issue? my coil is 57ohm1 point -

Tesla with A811 tube

JerryAcert reacted to ptkindt for a topic

I made a Tesla transformer with a A811 tube. I did not force anything, it can run for hours. The making of: http://www.youtube.com/watch?v=H7nivw7zxNM The result: http://www.youtube.com/watch?v=Mp721VgxWQI1 point -

10,000V at 0.02A is 200W which is a lot of power for a little power supply.1 point

-

Electronic Gun !!!!!!!!!

Jordan&tiffany reacted to Silent Jack for a topic

[i would not encourage children to develop high tech weaponry and would firmly discourage them from using them on themselves or others.] I saw a project online once that took a page from the XREF taser shotgun rounds, concept. It used pressurized air to propel a charged disposable camera capacitor, prongs first out of a simple barrel. Interesting concept, though from what I read, the 330V would be far to little to achieve the taser effect. That and I understand a specific waveform is needed to affect strictly skeletal muscle and not cardiac muscle. Seems like a safety concern to me.1 point -

Overload Protector A16 ???

joeydennis11 reacted to Hero999 for a topic

It could be used as a switch, amplifier or (as you've said) part of a current limiting circuit. Bipolar transistors have so many applications that it's impossible to tell you what it's doing from what you've said. For example if I asked you "I've seen a flat head screw; what's it holding together?", how could you know the answer? If you post a picture I might be able to tell you but even then the only way is to post a schematic.1 point -

after removing of ebook files, the page is not visited so much and not updated messages as before...1 point

-

You are breaking the hearts of all the hobbysts who can not afford the cost of buying the books from amazon. most of us are ametures using the books for refrences or some other information. i dont think someone is making millions using these ebooks.1 point

-

LM3914 pspice library

joeydennis11 reacted to audioguru for a topic

Hi Maliki, National Semi doesn't have a spicy ( ;D) model for their LM3914. I looked on Google for Spice and then Pspice Model For LM3914 and found many people asking for a model too. One guy found a similar model to pspice online at a university. There are many French links. Parlez vous francais? Not me, and I hate Google's horrible translator. ;D1 point -

1 point

-

T7900 and T7778A datasheets?

FranceRouze reacted to hotwaterwizard for a topic

I'm having a real hard time with these! Here is what I have so far. These only mention your chips but, it is something. http://www.eio.com/lcd.htm http://earthlcd.com/zlcd/downloads/lm24014w.pdf http://forum.microchip.com/tm.asp?m=29114 http://www.mpja.com/download/14619opap.pdf1 point