Search the Community

Showing results for tags 'pcb'.

-

1.Countersink hole A conical hole which is cut to allow the flat head screw to be used is called a countersink hole. It can also be called as a conical hole that is cut into a PCB laminate, or a hole created by using a drill. The main purpose is to let the head of a countersunk screw, once it is inserted and screwed down in the hole, to sit flush with the surface of the laminate. The cone shaped hole, which is cut into the PCB laminate, is a countersink. It is generally used to permit the tapered head of a screw to sit flush with the top or bottom of the laminate. It is mainly used, so that the flat head screw can sit flush with the surface to have a clean look and installation. To ensure correct design for manufacturing, most manufacturers require the details of the hole diameter. They also need to know if the hole is plated or not. Knowing if the hole is plate or not is critical because in some situations an unplated hole may be grounded to the framework, which could cause a problem that would require plating to correct. Countersinks usually have an 82 degree or a 90 degree angle; however, other angles are possible that the customer would need to provide to the PCB fabricator. For accurate drilling of countersink holes, the following information is needed: 1. Which side of the board is the countersink hole should be drilled, on top or bottom? 2. Is the sink and shaft to be through plated or non-plated? 3. Taper angle or countersink angle 4. Countersink diameter 5. The finished diameter of the shaft of the hole 6. Depth of the countersink is to be drilled Below is an illustration which provides an example of a countersink hole :

-

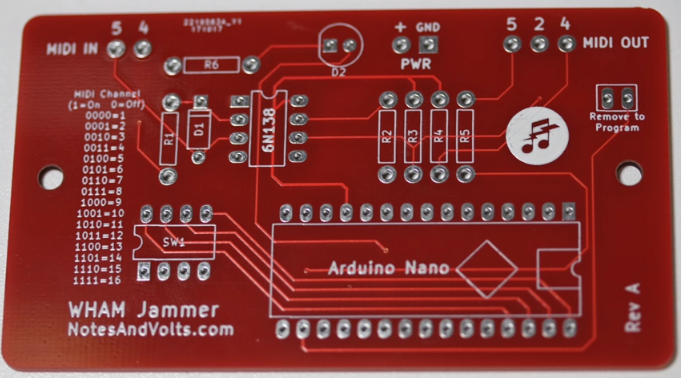

I ordered my first PCBs from www.jlcpcb.com last week, and I am very impressed. I usually get my PCBs from seeedstudio ..... but now it will be JLCPCB. It's my firist order. Unimaginably, my first order , shipping ,free !!!! Just cost $2 !!!! Can't unbelive this. I order the senond, shipping ,display $18 to Candan. The customer service told me: free shipping just for first order. Here is quick review, in point form; · Great web site and is update. Can actually see PCB manufacture process of order, tracking, design, etc.. everything is in one place. Nice. · 5 days to arrive at my door, from time of order. I am in Candan.· PCBs packed very well. · Silks screen is very detailed and 'fine' · Price is the cheapest... · Shipping is with DHL, which i like. I like red I have a new try and choose a red mask. I like red, it’s bold and eye-catching. Green with white silkscreen.green is probably the best of all the available colours in practical terms. Below boards from JLCPCB. They were all cut perfectly to size, all perfectly etched and drilled, tinned. Inspection of fine traces on the board for defects is best done with some form of magnification. Electrically, the SIMM tested fine.

-

With the rapid development of the Internet of Things, more and more intelligent products such as intelligent home, intelligent transportation, intelligent city and so on have emerged in the market. These terminals rely on wireless transceiver module to realize information transmission and reception. As a result, we know that wireless modules are indispensable in the use of the Internet of Things.Wireless modules often need a backplane to match them, enabling them to perform better in their application.So the design of our backplane is particularly important. How to design is our concern. Today, let's briefly talk about how to design the backplane of our wireless module. Most importantly, we should pay attention to the space reserved for wireless modular antennas. Our most common antennas are ceramic antennas, PCB loaded antennas, and external antennas (just a generic name here). External Antenna Fig.1 is a typical external antenna-based wireless module backplane design.From Fig.1, Fig.2, we can see that on the left are USB interface, LDO, plug-in interface, Jing Zhen, USB-TTTL chip, module bottom without components and line. When we design the module, we try not to walk high-speed lines and place components sensitive to RF signals. The module is placed in a separate area to prevent interference with other functional modules from causing communication problems. The outboard antenna SMA is on the far right, preventing the effects of RF signals on other sensitive devices after they are radiated through the antenna. As we can see from Fig.3, when we draw the RF line from the base plate to the outside SMA head, the RF line needs to have an accompanying hole, which allows a vortex between the RF signal and the ground, a circuit in space, to absorb part of the radiated signal, thereby reducing the effect of radio-frequency signal radiation on other signals inside the plate.Another reason is the Faraday shield, together with a hole that effectively prevents other signals from interfering with it. Ceramic Antenna, PCB Board Antenna Ceramic antennas and PCB loaded antennas are similar in design. This is the unified explanation here. From Fig.4, we can see that the left side is the same design as Fig.1. This is no longer the case here, but focus on the placement of the right antenna. We can see that when we are designing, we need to place ceramic antennas at the edge of the board (sometimes because of some restrictions, the antenna needs to be placed inside the backplane, then we need to carve out the position of the antenna and hang the antenna outside the backplane so that the antenna can radiate out the radio signal better and communicate better. Of course, there are more factors involved in baseplate design, which requires a combination of actual conditions and often a compromise.

-

- pcb

- pcb design

-

(and 1 more)

Tagged with:

-

Has someone the new datasheet from the JYQD_V7.3E3 motordriver (24V) (that one with the hall sensor pads on the side and not the regular one that it is aligned) DC-12-V-36-V-15A-500W-Senza-Spazzola-Del-Motore-Sala-BLDC-Bordo-di-Driver.jpg_640x640q70.jpg_.webp

- 6 replies

-

- motor driver

- driver

- (and 4 more)

-

Choosing the right Surface Finish for Chip on Board assembly is crucial. One of the most frequent questions we are asked at KingCredie Technologies is how should my PCB be plated in order to ensure wire bond-ability. PCB Plating for Chip on Board Assembly must be planned in advance to ensure manufacturability of the device. This planning begins with design rules and selecting the wire bond method to be used. Common wire bond materials include aluminum or gold wire. Aluminum Wedge Wire Bonding and ENIG Plating One of the most common wire bond methods for COB assembly is aluminum wire bonding. For aluminum wire bonding to a PCB the plating can be a low cost method known as ENIG or Electroless Nickel with Immersion Gold. With ENIG plating a PCB with Copper traces is plated with a Nickel layer and then the nickel layer has a flash gold layer on top. The Flash Gold is a barrier layer to protect the Nickel from oxidation. The wire bonding connection is actually from the aluminum wire to the Nickel plating. The main advantage of this method is inexpensive plating and relatively easy wire bonding. The disadvantage is Aluminum wire bonding is less flexible than gold bonding and generally requires larger bond pad pitch compared to gold bonding. Gold Ball Wire Bonding and soft gold plating For Gold Ball Bonding to Printed Circuit Boards a thick layer of soft gold has traditionally been required. In this Case the copper traces on the PCB are plated with a nickel layer and then a soft gold layer measuring between 15 and 30 micro-inches. The gold is electroplated and when plated correctly provides an excellent surface for wire bonding. This method has the advantage allowing for fine pitch gold ball bonding. The disadvantages are high cost and the thick gold layer can cause reliability problems with surface mounted components due to gold dissolution into the solder. Gold Ball Wire Bonding with ENEPEG plating In recent years Electroless Nickel, Electroless Palladium, Immersion Gold plating has been proven to be the best compromise between cost and manufacturability. This method of plating is known and ENEPIG and is common referred to as the universal plating method. It is called universal plating because it offers good wire bond ability and good solder ability. It is suitable for RoHS solders as well as Eutectic SnPb solder. The typical plating thickness is 100 to 150 micro inches of nickel followed by 4 – 10 micro inches of palladium followed by 1-2 micro inches of gold. ENEPIG is suitable for both Gold and Aluminum wire bonding. Additionally, With recent increases in the price of gold price to levels above US$1200 per troy oz, the production cost of electronic device that required thick gold electroplating becomes extremely difficult to control. Since the cost of palladium metal has remained relatively low in comparison to gold, an opportunity for cost saving by replacement of gold with palladium is now available. At KingCredie for PCB plating with Chip on Board we recommend using ENEPIG as a preferred plating method.For more information,tell us what you want to know.

-

- pcb

- pcb design

-

(and 3 more)

Tagged with:

-

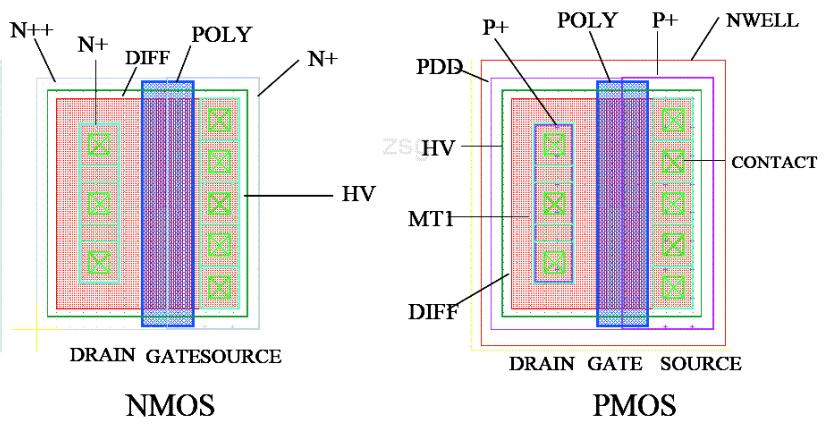

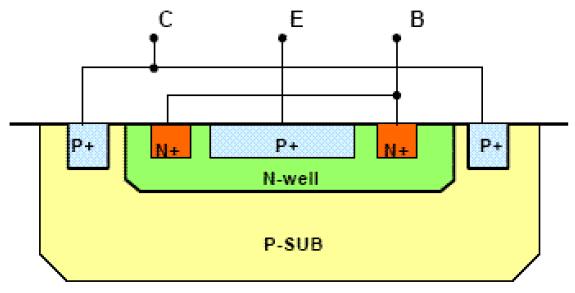

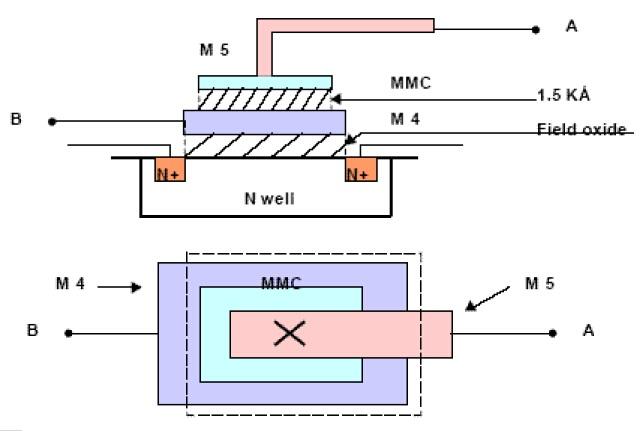

PCB Layout Tutorial: For High-Quality PCB Design http://www.apogeeweb.net/article/89.html Asymmetric source/drain MOS transistor LPNP MMC

-

Every digital clock has a crystal inside it to keep track of time. This crystal is not only present in the clock but also present in all computing real-time systems. This crystal generates clock pulses, which is needed for timing calculations. Although there are some other ways to get clock pulses for higher accuracy and frequency, but the most preferred way is to use crystal to keep track of time. Here we will DS3231 RTC IC to build an Atmega16 based Digital Wall Clock. DS3231 RTC has a highly accurate crystal inside it, so no external Crystal oscillator is needed. In this Digital Clock Project, ten common anode 7-segment displays of 0.8-inch are used to display time and date. Here seven segment displays are used to show hour, minute, date, month and year. Our PCB design also has options to display seconds and temperature, which can be displayed by adding more display units. Circuit Diagram and Explanation There are two parts of this Digital Wall Clock Circuit, one is display part which has 5 pairs of 7-segments on five different PCB boards and another is controlled Unit part which is responsible for fetching time from RTC chip and send that data and time to 7-segment display. As we have used 10 seven segment displays so we cannot connect each display with a separate IO port. So here multiplexing technique is used to connect multiple seven segments using fewer pins of microcontroller. LED pins a,b,c,d,e,f,g,h of seven segment display is connected to PORTB of atmega16 parallel. Here we have used 10 seven segment displays so we need 10 control pins which are connected at PORTD, PORTA and PORTC. RTC DS3231 having an internal crystal is connected to PORTC’s SDA and SCL pin because this chip works on I2C communication. Interfacing method of this chip is the same as DS1307. We have used DS1307 with Arduino, Raspberry Pi and 8051 MCU. Same code can be used for both DS3231 and DS1307. For one display board, two seven segment displays and 2 LED are used. So here we have five different display boards to display Time in Hours and minute (HH-MM), and date in DD-MM-YY. PCB Design and fabrication for the Digital Clock For this Atmega16 based wall clock project, we have designed two PCBs. One is for Control unit which is used to control all the operations of the project and second part is for displaying the time and date on seven segment displays. Display part contains five pairs of 0.8 inches seven segment display. So by assembling 5 pieces we have the complete Digital Clock. To multiplex 7-segment displays, Data line of the 5 PCBs will be connected to the same port of control unit and control line is connected different pin of the control unit. Below are the top and bottom views of PCB layouts of one Display board which consists two seven segment displays: Below are the top and bottom views of Control Unit PCBs Ordering the PCB using PCBGoGo There are many PCB fabrication services are available online, but as I used PCBGoGo previously in one of my other projects, I found it cheap and hassle-free as compared to other vendors. Here are the steps to order PCB from PCBGoGo: Step 1: Get into www.pcbgogo.com, sign up if this is your first time. Then, in the PCB Prototype tab enter the dimensions of your PCB, the number of layers and the number of PCB you require. Step 2: Proceed by clicking on the Quote Now button. You will be taken to a page where to set few additional parameters if required like the material used track spacing etc. But mostly the default values will work fine. The only thing that we have to consider here is the price and time. As you can see the Build Time is only 2-3 days and it just costs only $5 for our PSB. You can then select a preferred shipping method based on your requirement. Step 3: The final step is to upload the Gerber file and proceed with the payment. To make sure the process is smooth PCBGOGO verifies if your Gerber file is valid before proceeding with the payment. This way you can sure that your PCB is fabrication friendly and will reach you as committed. Now PCBGoGo will take some time around 10 min to 1 Hour to review your Gerber file. After completion of the review, you can proceed with the payment. Assembling the PCB After the board was ordered, it reached me after some days though courier in a neatly labeled well packed box and like always the quality of the PCB was awesome. I am sharing few pictures of the boards below for you to judge. I turned on my soldering rod and started assembling the Board. Since the Footprints, pads, vias and silkscreen are perfectly of the right shape and size I had no problem assembling the board. The board was ready in just 10 minutes from the time of unpacking the box. Few pictures of the board after soldering are shown below. Testing the Digital Clock Complete code is given at the end of this tutorial, just connect the PCBs as shown in the circuit diagram and upload the code into Atmega16. And you will see time and date appearing on the ten Seven segments displays.

- 1 reply

-

- pcb

- pcb assembly

-

(and 1 more)

Tagged with:

-

The board is made very precisely, it's clean and very pleasant to touch. Markings on the silkscreen layer are very good readable. Soldering does not cause trouble, tin adheres very well to soldering points with a small amount of flux. It is also worth mentioning that the PCB is very robust to desoldering. The company is very solid, although you order 10 pieces, you get at least 1 PCB more for test, prototype, present, etc. When I signed up for an account, I also got a $20 coupon for free. Excellent construction and assembly work done by PCBgogo.No problems encountered, highly recommended.

-

- pcb

- pcb prototype

-

(and 1 more)

Tagged with:

-

My team has decided to make a prototype of an "Advanced" SPD by incorporating an electronic circuit which shows notifications and an additional circuit which shows earth faults if any in a circuit. As we were planning to use MOVs with Thermal cut-off, the notification incorporation is not a big deal. But the problem is that, there is only 20kA Imax for the proposed model of EPCOS and we require models with more than 40kA which is not available in the MOVs with Thermal cut-off so we have decided to use normal MOVs of that capacity for which there is no notification/monitor lead. Please propose any alternative or a better idea to put this things together. Also we are trying to use GD tube/Spark Gaps in the higher models along with MOVs for which the notification is again a concern. valuable suggestions please!!!

-

- spd

- surge_protection

- (and 9 more)

-

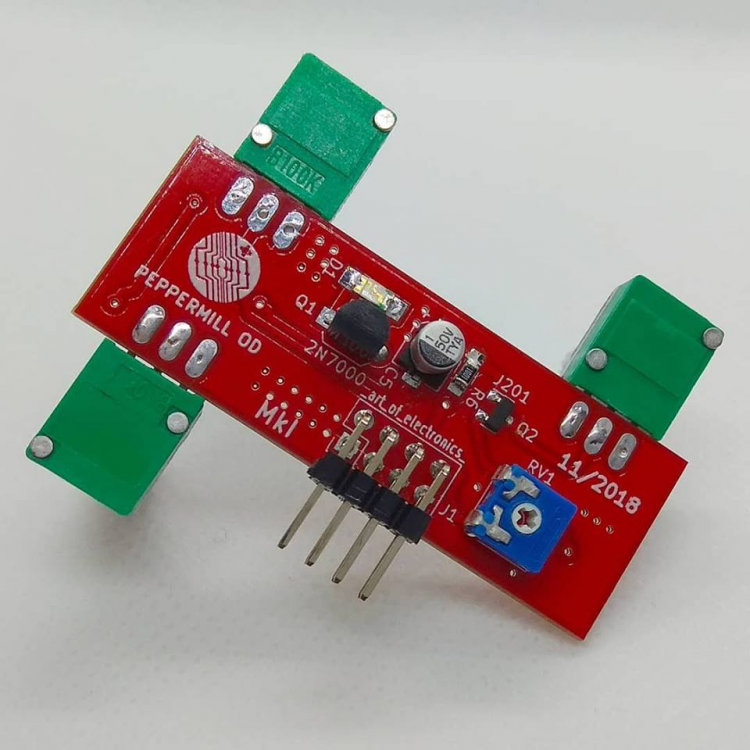

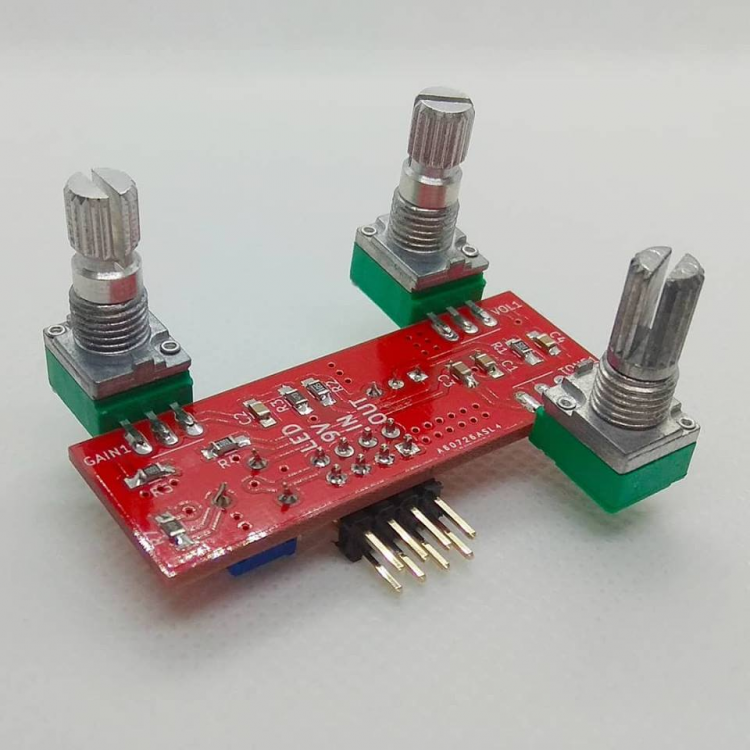

Hello guys, Another 1590B marvelous pedal effect - the peppermill overdrive (original concept found on #runoffgroove ). Looks pretty much the same as CMOS Fuzz (minimalistic raw metal design) but shines red instead of blue. In case someone is wondering I'm not changing my main coure from electronics to guitar effects. I just decided to combine three of my passions (electronics, guitar, CAD/diy) and show some new type content along with mechateonics engineers flexibility. I'll be back with some hardcore electronics content as soon as I manage to overcome some communication issues. pcb from: PCBGOGO

-

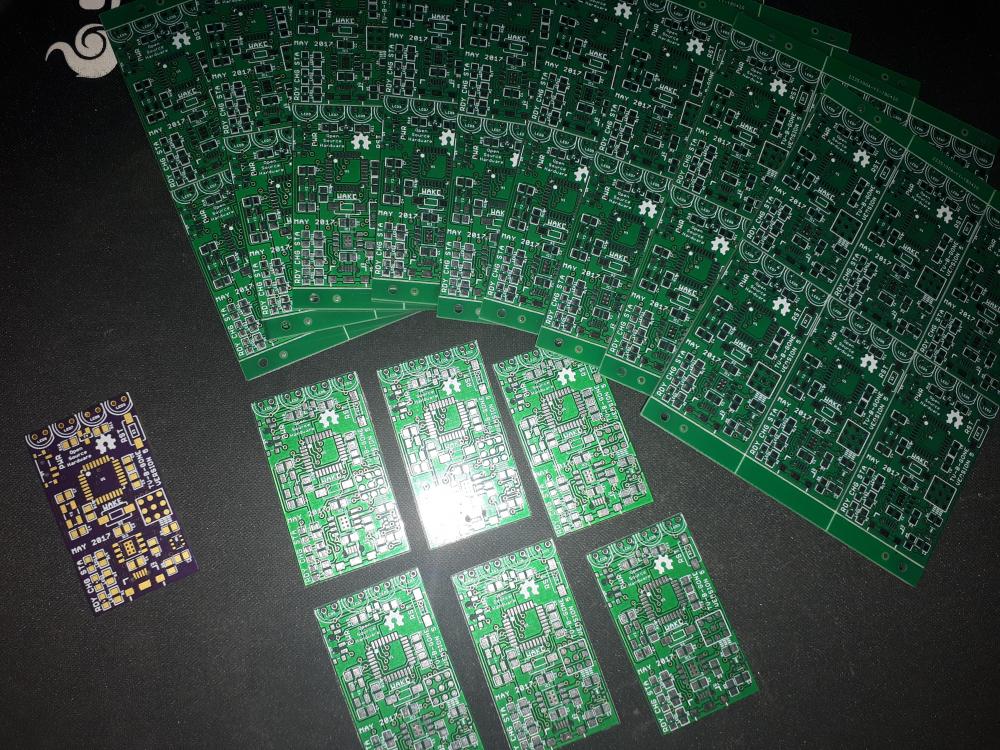

Hello guys, im a 17yo student that loves electronics and i started working on custom tv-b-gone based on arduino version with rechargeable battery and i needed pcbs for it. Firstly i ordered pcbs(on the left) that were $3 PER PIECE and then i found out for JLCPCB. They have amazing offer of 10pcs 10x10cm pcbs for $2!! I could fit 6 tv-b-gone boards on one 10x10cm pcb and multiply that by 10 and you get 60 pcbs for $2!!! When i first ordered i tough that its just a low quality board but when i received them in 2 weeks (which is really fast) i was SURPRISED by QUALITY for that LOW PRICE. First there was no shorts between any of the tracks. My design has really tight traces and they came out perfectly! Silk screen is also really good and vias are covered fully which gives boards nicer look. Panel by JLCPCB really made my job easier and it is also good, VCut is perfect, you just can snap the boards with hands and sand the sharp edges. They also make solder paste stencils which are helpful with pcbs with 95% of smd components and its also cheap, only $7 for big stainless steel stencil! Ordering is really simple. Go to https://jlcpcb.com/ and upload your gerber files in zip or rar format (there is also tutorial how to export gerber). If you want panel select "Yes" for "Panel By JLCPCB" and enter how many boards you want in a row and column. Im just really surprised by quality and looks of the pcbs. If you are interested in the project here are some video clips and soon there will be clip of assembling one with board from jlcpcb. https://jlcpcb.com/ https://jlcpcb.com/ https://jlcpcb.com/

-

Hello, Everyone!!! I am Katy Radcliff and new to this forum. I love to repair and rework PCB's, so I hope I will get something new related to PCB's and other electronic things.

-

Hi all, I found a ver very good and really cheap pcb service! Its called PCBWay, and they have cheap 2layer 10x 10x10cm pcb for just $5! and shipping to the Netherlands was just $7!(china post) And they have real good and very kind customer service witch reply back very fast and every question i had got answered in not time AND they give you $5 free for your first order! Pcb's look good and came fast. All pcb's where exported with eagle. I got 2 extra pcb's(win win) probably if a pcb fails check or something. I used blue silkscreen with white text for the pcb and also bought some project pcb's with holes wich i got in 5 collors and look absolutly great! The blue silkscreen looks absolutly perfect, its really perfectly alligned! and the text looked good, it looked a little bit blocky but still it looks great! I ordered pcb's for a adafruit solar charger clone as i needed 9 of them and just didnt have the money to buy them. Since i already had all the components i needed exept the pcb's i just bought the pcb's since their charger is opensource and created them my self to save some costs.(i'll probable sell the last one i dont need) At first i thought if i had to buy the comonents also it all would be more expensive but i calculated if i wanted to create 10 solar chargers and bought all components from aliexpress and bought the pcbs from pcbway i save around $30 to my suprise!!!!!(first time self build a product is cheaper then buying) The chargers are for my solar powered raspberry pi zero powered wireless timelapse and livestream camera's, witch will be mounted in my backyard pointing at bird homes and one as security camera for my back yard gate to watch intruders. I already finished one of the charger and it looks really really impressive with the blue silkscreen! I'll maybe upload some pics of my assembled pcb's and bare pcb's soon for other peaple to check and i am probably going to clone the adafruit powerboost 1000 charger too!(because its cheaper offcourse, i still bought a lot of products from adafruit so i am still supporting them). The pcb's are of good quality, no broken or half traces, all boards are straight and not bend, all boards got the silkscreen and white text right so they just look amazing! I really really recommend this service to everyone and i am defenitly going to try their 4 layer too some time!! And they also offer cheap assembly services so maybe i will try that sometime too! Since i am very very and very happy with my pcb's i am defenitly buying from them again and again in the future and recommend them to everyone! So now i want to know who else used this service and had good experience or wants to try it out? hope to hear from you all!

-

As a hobbyist,I learned so much from here and thanks very much for everyone. As pcbway manager,here is a good news I think will help hobbyist. In order to express our gratitude and help electronic hobbyist save cost,now we build a page to sponsor electronic hobbyist's pcb project (up to $100 coupon to your account),you can get the details from our sponsorship page.If you have any questions and suggestions,please reply to me here. The sponsorship link is here, (If this link break the rule,please tell to me and I will delete it,thanks Administrator)

-

- pcb manufacturer

- pcb

-

(and 1 more)

Tagged with:

-

Two questions: 1. How to guarantee the quality of BGA and QFN ? 2. What shall be minded for halogen-free process ?

-

PCBGOGO -Custom PCB Prototype Manufacturer ,is provide the best ever service in quick-turn PCB prototype, low & medium volume and low cost.The best PCB(printed circuit board) buying experience in the country today .PCBGOGO is committed to provide short and accurate lead time for PCB manufacturing job.The quickest lead time PCBGOGO can do is 12hours. And PCBGOGO has Instant online quote and detailed tracking system which will inform you the each process of the PCB boards. www.pcbgogo.com/f And now big promotion is coming.don't miss it.

-

(This is my 1st post in this forum and I will post many post in the near future. ) Printed circuit board design software This electronic design software is a license software professional edition. This is a PCB Wizard Professional edition with learning samples. This printed circuit board design software uses latest transistors, ICs, Resistors, Condensers, Triacs, Logic gates, Input also output components, digital meters, analog meters also oscilloscope also includes many type of Pin types. Just like SIL, DIL, and DO Etc. This printed circuit board design software[highlight #000000][color #000000][/highlight] packages includes 01 PCB Wizard Professional Unlimited Edition 02 Livewire Professional Edition 03 Bill of Materials Database Update 04 Examples Here is the download link of printed circuit board design software. http://tinyurl.com/zq9sd8f I will upload it soon. It’s Includes new facility to do more works. In the near future we will upload it to this playlist and wait for the latest update.

-

I have a PCB fabricator line which is specialized for electrical DIY lover or electrics engineers. All the fabricated PCB will be tested and ensured the quality. The fabrication of 5 pics usually costs 12-14 bucks for 100mm*100mm 2 layer board depending on the design. If you need the PCB very soon, I can get it for you as soon as 5 working days. Here is the basic stand of my fabrication: Layer: 1-10min trace width/ distance: 0.1mmmin via diameter: 0.15mmcooper thickness: 1oz/2oz/3ozblind/buried via: unavailableSolder Mask colour: Green, Red, Yellow, Blue, White and BlackIf my services suit to your needs, you can contact me by Email. I can get you a coupon or some nice gift from fabricator partner. Email: [email protected]

.jpeg.c31344da463863c78b381b78e9c76917.jpeg)

H8JK02UZ4773AQ7LB3.thumb.png.751f02586bea855db953ce0a444fbbbe.png)