Automatic Fan Controller

- Izhar Fareed

- http://www.extremecircuits.net

- izhar@gmx.us

- 46.615 Views

- moderate

- Non tested

Description

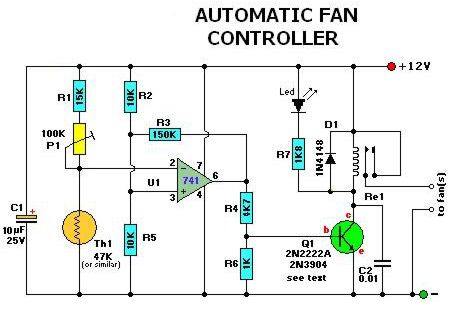

Th1, the 50K thermistor, is a standard type. Mine was a bar or rectangular looking thingy. Available from Tandy/Radio-Shack. Almost any type will do. I experimented with different models from 22K to 100K and all worked fine after replacing the trimmer pot. The one used in the above circuit diagram was a 50K model. This 50K was measured at exactly 25 °C and with 10% tolerance. The resistance increases as the surrounding temperature decreases. Tolerance for my application (cooling a large powersupply coolrib) is 10%. Another name for this thing is ‘NTC’. NTC stands for “Negative Temperature Coefficient” which means when the surrounding temperature decreases the resistance of this thermistor will increase. I replaced my thermistor for a 60K hermetically

sealed glass type since the environment for my application may contain corrosive particles which may affect performance on a future date. P1 is a regular Bourns trimmer and adjusts a wide range of temperatures for this circuit.

I used the 10-turn type for a bit finer adjustment but the regular type will work for your application. R1 is a ‘security’ resistor just in case the trimmer pot P1 is adjusted all the way to ‘0’ ohms. At which time the thermistor would get the full 12 volt and it will get so hot that it puts blisters on your fingers… :-)R3 feeds a bit of hysteresis back into the op-amp to eliminate relay ‘chatter’ when the temperature of the thermistor reaches its threshold point. Depending on your application and the type you use for Q1 and Re1, start with 330K or so and adjust its value downwards until your satisfied. The value of 150K shown in the diagram worked for me. Decreasing the value of R2 means more hysteresis, just don’t use more then necessary. Or temporarily use a trimmer pot and read off the value. 120K worked for me.

Transistor Q1 can be a 2N2222(A), 2N3904, NTE123A, ECG123A, etc. Not critical at all. It acts only as a switch for the relay so almost any type will work, as long as it can provide the current needed to activate the relay’s coil. D1, the 1N4148, acts as a spark arrestor when the contacts of the relay open and eliminates false triggering. For my application the 1N4148 was good enough since the tiny relay I used was only 1 amp.

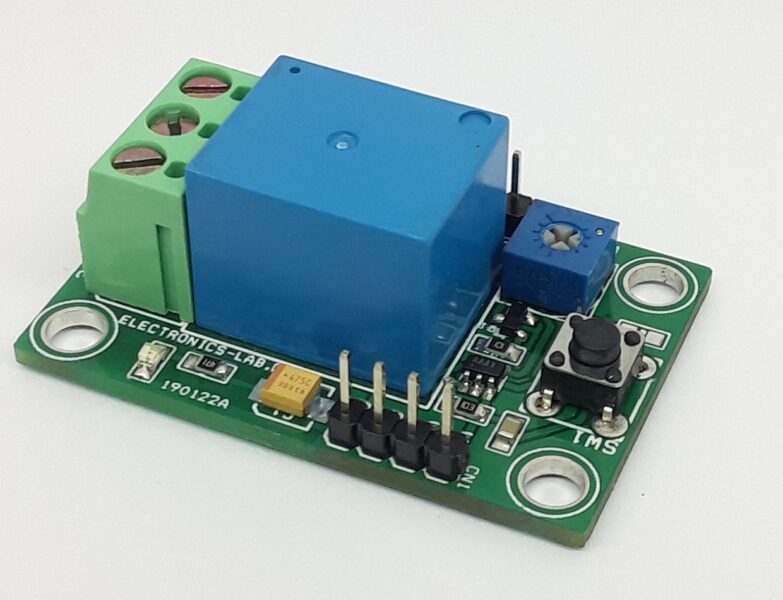

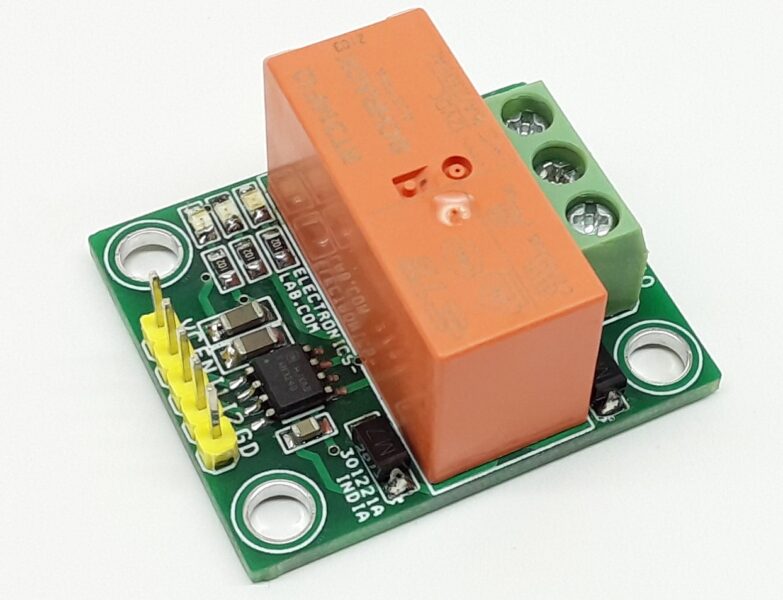

However, you can use a large variety of diodes here, my next choice would be a regular purpose 1N4001 or something and should be used if your relay type can handle more then 1 amp. If you like to make your own pcb, try the one above. The pcb is fitted with holes for the relay but may not fit your particular relay. It was designed for a Aromat HB1-DC12V type.

The variety and model of relays is just to great. How to mount it then? Well, I left ample space on the pcb to mount your relay. You can even mount it up-side-down and connect the wires individually. Use Silicon glue, cyanoacrylate ester (crazy glue), or double-sided tape to hold the relay in place. Works well. Note that the pcb and layout is not according to the circuit diagram in regards to the hookup of the fans. The PCB measures approximately 1.5 x 3 inches (4.8 x 7.6mm) If you print the pcb to an inkjet printer it is probably not to scale. Try to fit a 8-pin ic socket on the printed copy to make sure it fits before making the pcb…

where is the components list

There is no components list for this project. All parts are marked clearly on the schematic.

What is 741 ?

It’s LM741 Operational Amplifier – OPAMP

“Decreasing the value of R2 means more hysteresis”

Should that not be ‘R3’?

WHAT KIND OF RELAY IS THAT?

It’s a 12V general type relay.