Low cost / Automatic Emergency Light

- Izhar Fareed

- http://www.extremecircuits.net

- izhar@gmx.us

- 53.177 Views

- moderate

- Non tested

Description

Here is a white-LED-based emergency light that offers the following advantages:

- It is highly bright due to the use of white LEDs.

- The light turns on automatically when mains supply fails, and turns off when mains power resumes.

- It has its own battery charger. When the battery is fully charged, charging stops automatically.

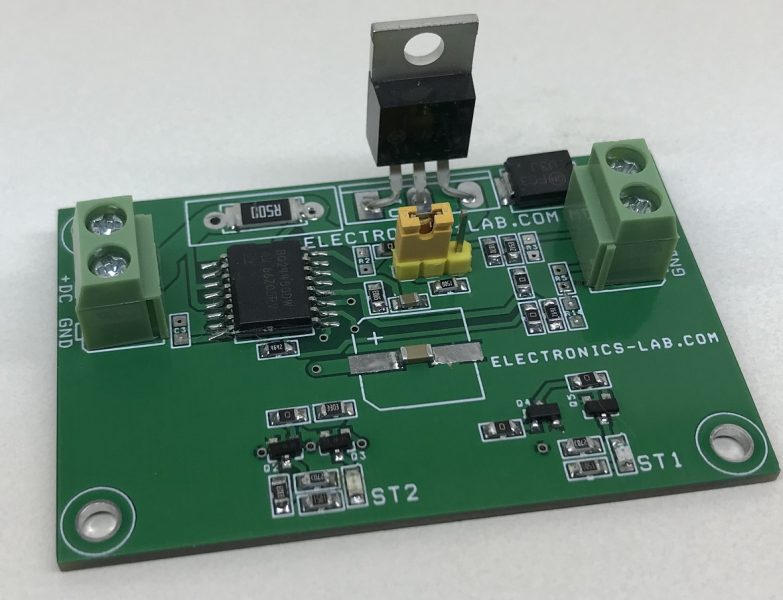

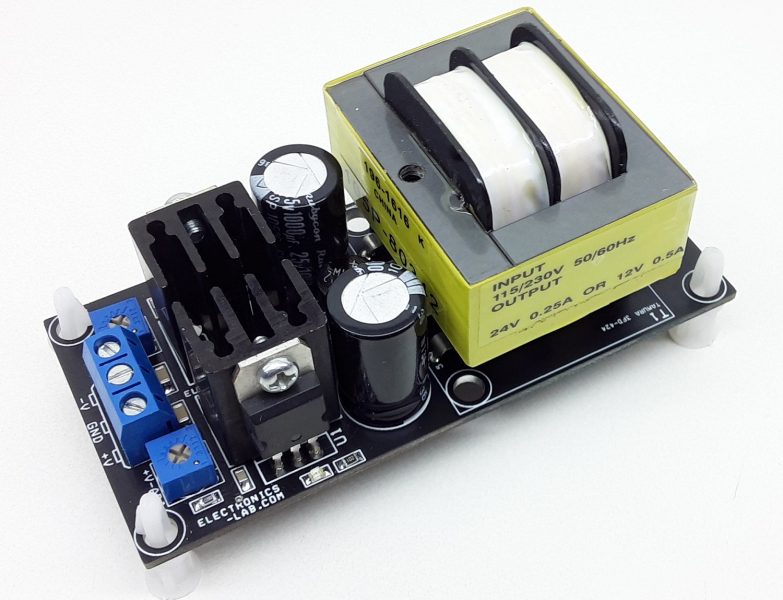

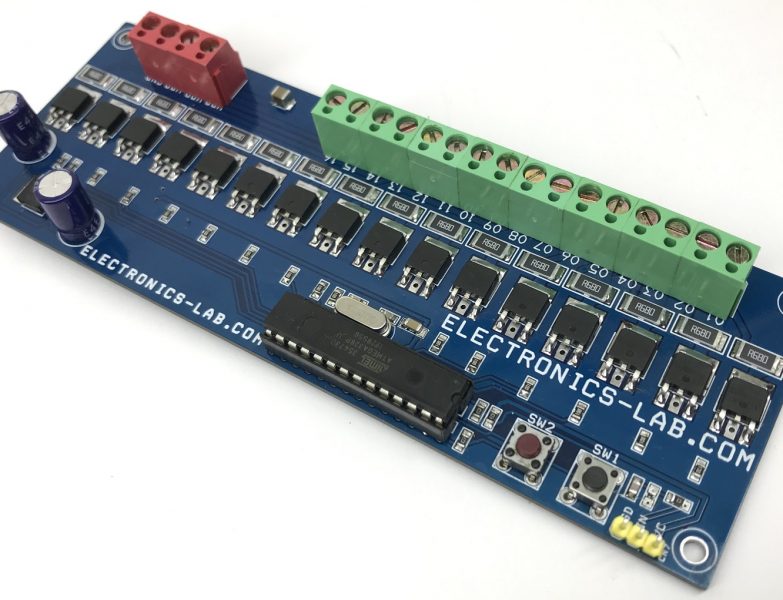

The circuit comprises two sections: charger power supply and LED driver.The charger power supply section is built around 3-terminal adjustable regulator (IC1) LM317, while the LED driver section is built around transistor BD140(T2). In the charger power supply section, input AC mains is stepped down by transformer to deliver 9V, 500mA to the bridge rectifier, which comprises diodes (IN4007x4). Filter capacitor (25v/1000uf)eliminates ripples. Unregulated DC voltage is fed to input pin 3 of IC1 and provides charging current through diode IN4007(D5) and limiting resistor (16ohm)R16. By adjusting preset 2.2K(VR1), the output voltage can be adjusted to deliver the required charging current. When the battery gets charged to 6.8V, zener diode conducts and charging current from regulator (IC1) finds a path through transistor BC547(T1) to ground and it stops charging of the battery. The LED driver section uses a total of twelve 10mm white LEDs.

All the LEDs are connected in parallel with a 100-ohm resistor in series with each. The common-anode junction of all the twelve LEDs is connected to the collector of pnp transistor T2 and the emitter of transistor T2 is directly connected to the positive terminal of 6V battery. The unregulated DC voltage, produced at the cathode junction of Bridge(Diodes), is fed to the base of transistor T2 through a 1k resistor. When mains power is available, the base of transistor T2 remains high and T2 does not conduct. Thus LEDs are off. On the other hand, when mains fails, the base of transistor T2 becomes low and it conducts. This makes all the LEDs (LED1 through LED12) glow. The mains power supply, when available, charges the battery and keeps the LEDs off as transistor T2 remains cut-off.

During mains failure, the charging section stops working and the battery supply makes the LEDs glow. Assemble the circuit on a general-purpose PCB and enclose in a cabinet with enough space for battery and switches. Mount the LEDs on the cabinet such that they light up the room. A hole in the cabinet should be drilled to connect 230V AC input for the primary of the transformer. I have tested the circuit with twelve 10mm white LEDs.You can use more LEDs provided the total current consumption does not exceed 1.5A. Driver transistor T2 can deliver up to 1.5A with proper heat-sink arrangement.

Hello, what is thé part VR1 , 2.2 K?

VR1 is a common 2.2Kohm potentiometer used to adjust the battery charging current.

Thanks a lot

You are welcome.

I am still concerned by this potentiometer. How do I know the correct tuning to ensure correct charging of battery?

Thanks in advance

Adjust VR1 so you get around 200mA through the battery. To measure battery charging current you need to cut + wire of the battery and insert your multimeter probes on the two ends. Multimeter should be in current measurement mode.

Sir.. can 16R/5W resistor replaced with other?

You can replace it with two 8R resistors in series, each one at 2.5W rating

Tested above circuit. It works great however it takes 2-3 seconds to glow the LEDs after power cut. Can we use 12 V 7.5 Ah battery here? In that case what components values need to be changed to ensure trickle charging.

Planning to build one for my home. Please help 🙂

1.2k = ? watt

2.2k vr ? watt

180R = ? watt

1.2k and 180R = 1/4W and potensiometer 0.5W should be sufficient.

Can a 12V lead acid 9ah battery be used with this charger and if so what components would I have to change?

Can we use 12 V 7.5 Ah battery here? In that case what components values need to be changed to ensure trickle charging.

Rather very inefficient way to design a battery charger. Routing the output of LM317 across BC547/180 ohms resistor is a total waste of energy, just producing heat. Besides, marginal battery charging monitoring and no trickle charge.

It will work, but much room for improvements.

Thanks for your feedback. Yes i would agree, this is a pretty simple and low cost charger, so don’t expect any special characteristic or efficiency. If you have any suggestion for improvement, we would be glad to hear.Also, If you are looking for a better 6V battery charger check this: https://www.electronics-lab.com/project/6v-lead-acid-battery-charger-using-bq24450/