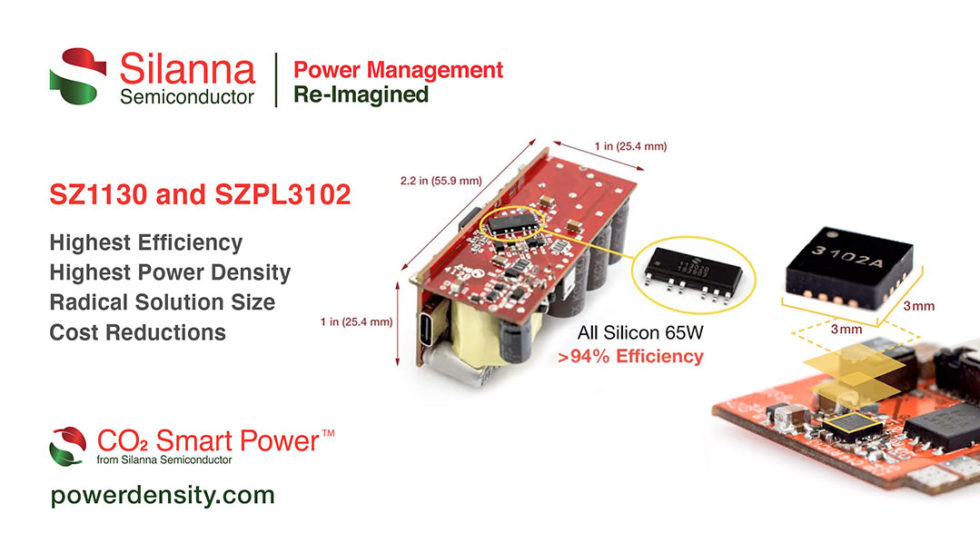

High-Efficiency ‘CO2 Smart Power’ Devices are Now Available for Volume Order

Silanna Semiconductor, The Power Density Leader, has confirmed that despite the worldwide chip shortage, it has been able to ramp up production of its ‘end-to-end’ family of power conversion semiconductors allowing it to satisfy customer orders in volume.

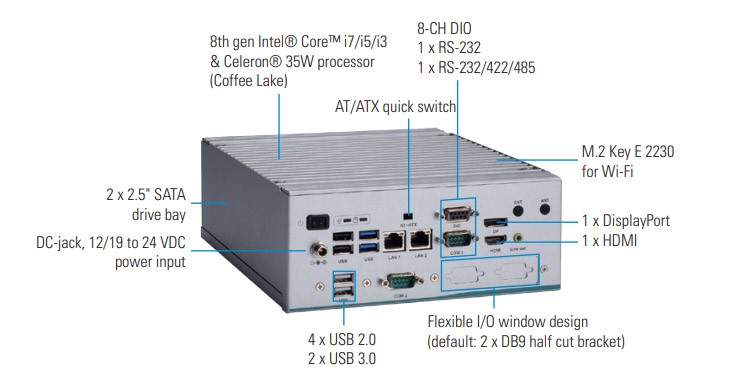

Silanna Semiconductor’s CO2 Smart Power™ portfolio, which includes active clamp flyback (ACF) AC/DC controllers and wide-voltage, high-frequency point-of-load (PoL) DC/DC converters, offers the industry’s highest levels of integration and efficiency. The unique nature of the technology combined with Silanna’s robust approach to management of its manufacturing and supply chain, has ensured minimum impact on production and lead times.

Mark Drucker, Silanna Semiconductor’s CEO, comments:

“While the lead time on a growing number of conventional power management ICs has risen, Silanna has been able to ramp up volume production. As a result, engineers choosing our AC/DC and DC/DC components for their power management schemes can realize all the benefits of improved efficiencies, reduced component counts and improved reliability while minimizing time-to-market.”

Silanna’s CO2 Smart Power™ portfolio of AC/DC and DC/DC devices provides complete solutions that address the ultimate power management challenge of delivering improved performance, unrivaled power densities and reduced BoMs while ensuring more efficient energy use. All of the products have been specifically designed for optimum performance and best-in-class power density. As well as minimizing energy use during operation, they also drive down the so-called ‘vampire’ power drain when on standby. In most cases, this translates directly into advanced products and systems that use less electricity and, therefore, contribute less to harmful CO2 emissions.

Silanna’s AC/DC controllers provide the ease-of-design of a simple flyback controller with all the benefits of an ACF design. This includes recycling the leakage inductance energy of the flyback transformer and limiting the primary FET drain voltage spike during the turn-off events. Employing Silanna Semiconductor’s OptiModeTM digital control architecture, these devices adjust the mode of operation on a cycle-by-cycle basis to maintain high efficiency, low EMI, fast dynamic load regulation, and other key power supply parameters in response to varying line voltage and load.

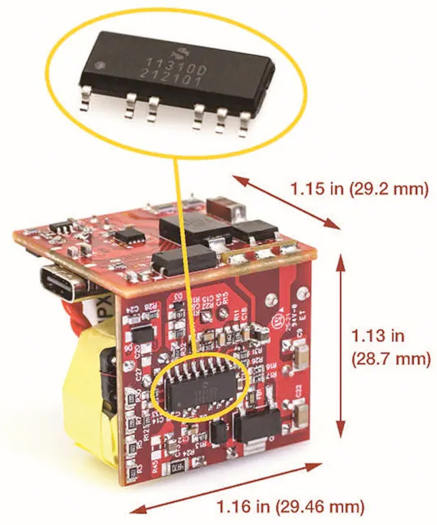

The high operating frequencies of Silanna’s PoL DC/DC converters mean smaller, lower cost, higher-performing output filters and significant size and cost reductions. Choosing these devices allows engineers to significantly increase the power density of their designs with volumes approaching 12% of that required by low-frequency alternatives.

The combination of best-in-class power density and efficiency, minimum no-load power and unprecedented BoM savings makes Silanna’s CO2 Smart Power technologies particularly suited to reducing the size, weight and energy consumption of single- and multi-port travel adaptors and device chargers.

Uncased power density is 22W/inch3, peak efficiency is >92% and no-load power (at 230Vac) is <20mW, according to Silanna, with flat efficiency across 90 to 265Vac, and more that 6dB margin over conducted and radiated EMI requirements – see the design test report to interpret this claim.

more information: RD-23 reference design report can be found here