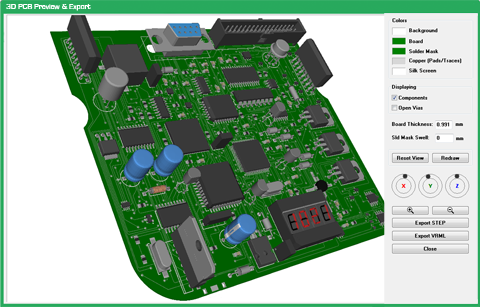

sfcircuits.com compares the top 5 PCB CAD Programs, DipTrace, Eagle, Altium, Pads and Orcad:

There are several programs available that range from simple and intuitive to highly sophisticated.

They range from free or inexpensive to high-end/premium.

They come feature-less or feature-heavy.

All of the tools are different and unique in their own way. Ultimately, your needs and preferences should drive what CAD program you use. This guide is structured to help you decide which is optimal or explore alternatives.

Comparing the Top 5 PCB CAD Programs – [Link]

Hi,

I have been designing PCBs since about 1975 (That show my age!) starting with XActo knives and Bishop Graphic thru today with a PADs ES Suite. I have used various OrCAD and Altium products through the ages and many others along the way. I put myself through U of MD EE doing PCB layout and design.

Which tool to use? Wow does that depend on the person and where you want to go. Doing a design a year for yourself is very different that doing 10 a month for other people. (Other people are much more demanding.)

The first big question is “Who will design the schematic.” Using a schematic capture front end that is “Native” for you PCB tool is a really smart way to go. If you do this for a living (at times I do that) it will never happen. You need to work with, and take data from the customer, whatever schematic tool they use. End of Story.

Doing it for a living means time is $$$. If for yourself then things are different.

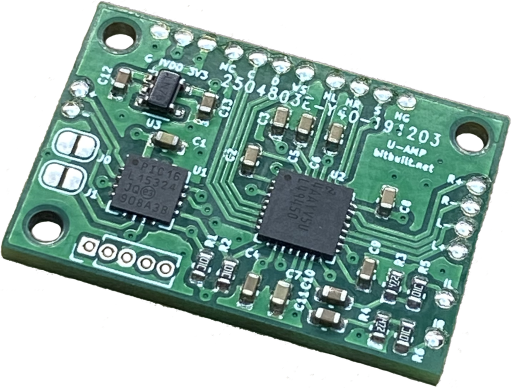

Probably the worst case issues in PCB design is doing something like power supply design (analog) or DDR3 routing. Yes it takes experience but it also takes tools. The DDR3 is probably the worst, you MUST have something like the Hyperlynx functions (Field Solver) or you are dead meat.

The next “Function Down” is power plane management. You must have the ability to design complex power plains AND execute continuity verification. If you are going to screw up a PCB design it will probably be power planes. (Well getting a footprint wrong is probably more common.)

A huge issue is part library management. Every tool claims great parts management but these buy you a big ZERO when you are designing jobs for other customers. I started out using Parts & Vendors a long time ago for parts management and used my own software tools to merge my footprint and vendor info with the customer data I receive. Now even if you roll your own boards you still need to buy parts and have things assembled. Schematic library tools are, in general, terrible database tools, I mean really bad. So I forget about trying to load a schematic with attributes to manage downstream functions (I often cannot touch the customers schematic) and I maintain these attributes in a database parallel to the job. Driving assembly is a really important subject for me. As a sample output see: http://www.kondner.com/files/BB25E_SMT.pdf I also helped setup http://www.aapcb.com.

For a DIY person with simple boards the freebie tools are fine. For a closed shop Altium is pretty good. For doing jobs for others PADs and its open .ASC format is really good. For high speed design you gotta have Hyperlynx type functions, gotta.

So I use PADs (ES Suite) for PCB Design, typically OrCAD for schematic (or my customer provides a netlist) and custom code to manage all my parts. I bought Altium, learned it well, but wend back to PADs. The schematic front end for PADs was “Logic” (EOL for maybe a decade) and now DX Designer (AKA ViewDraw) which is not “Native” to PADs by my definition, I won’t touch it myself. About 90% of my customer use OrCAD and all the others easily generate PADs netlists. (A really simple netlist format.)

Also, I like the SPECCTRA auto-router., a huge help on some jobs.

As for the database tools that I use to eliminate the need for schematic attributes see: http://www.partsync.com

And samples of schematics and BOMs I produce at http://www.sunduino.com

All these tools are free or very low cost. Take a look and let me know how I can help.

Thanks,

Bob K.

No KiCAD? Sheesh