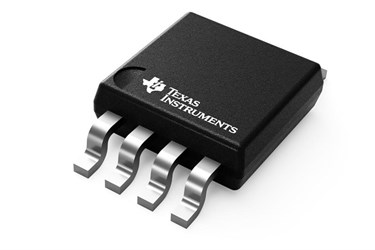

Texas Instruments has introduced a 3D Hall-effect position sensor. With the TMAG5170, engineers can achieve uncalibrated high precision at speeds up to 20kSPS for faster and more accurate real-time control in factory automation and motor-drive applications.

The sensor also provides integrated functions and diagnostics to maximize design flexibility and system safety, while using at least 70% less power than comparable devices.

The TMAG5170 is the first device in a new family of 3D Hall-effect position sensors that will meet a wide range of industrial needs, from high performance to general purpose.

“Smart factories have an increasing number of highly automated systems that must operate in a more integrated manufacturing flow while simultaneously collecting data to control processes,” said Noman Akhtar, senior research analyst, Omdia.

“3D position-sensing technology that delivers higher accuracy, speed and power efficiency is essential for automated equipment to quickly deliver precise real-time control for increased system efficiency and performance while reducing downtime.”

Achieve faster, more accurate real-time control

Texas Instruments claim that the TMAG5170 is the industry’s first 3D Hall-effect position sensor to provide a low 2.6% full-scale total error at room temperature.

It also features a drift of 3% total error, 30% lower than the next closest competitor, along with at least 35% lower error than comparable devices in the presence of a cross-axis field.

Together, these features enable the TMAG5170 to deliver higher accuracy than any other 3D Hall-effect position sensor, eliminating the need for end-of-line calibration and off-chip error compensation, and simplifying system design and manufacturing. To achieve faster, more accurate real-time control, the sensor supports measurements as high as 20kSPS for low-latency throughput of high-speed mechanical motion.

Maximize design flexibility and system safety with integrated functions and diagnostics

The TMAG5170 eliminates the need for off-chip computation and enables flexible sensor and magnet orientations by integrating features such as an angle calculation engine, measurement averaging, and gain and offset compensation. These features simplify design and maximize system flexibility, enabling faster control loops, reduced system latency, and simpler software development, regardless of sensor placement.

The sensor’s integrated computation functions also reduce the system’s processor load by as much as 25%, enabling engineers to use general-purpose microcontrollers (MCUs) such as TI’s low-power MSP430 MCUs to minimize overall system cost.

Additionally, the TMAG5170 increases safety with a set of smart diagnostic capabilities, such as checks for communication, continuity and internal signal path, as well as configurable diagnostics for the external power supply, magnetic field and system temperature. This allows engineers to customize a safety scheme at both the chip and system level for long-term reliability and lower design costs.

Increase power efficiency by at least 70%

The TMAG5170 provides multiple operation modes to reduce power consumption by at least 70% compared to other linear 3D Hall-effect position sensors while maintaining system performance. These configurable modes enable engineers to optimize power across a 1-SPS to 20-kSPS sampling range for battery-powered devices or light-duty modes where system efficiency is paramount.

Package, availability, and pricing

The TMAG5170 is available now from TI.com in an 8-pin, 4.9-mm-by-3-mm thin shrink small-outline package (VSSOP). Pricing starts at $1.139 in 1,000-unit quantities. Multiple payment and shipping options are available.