Organic Photovoltaic Solar Cells: Conventional Structure Achieving Over 20% Power Conversion Efficiency in Lab

The solar industry is constantly evolving with new technologies and products. One of the most promising advancements is the third generation of photovoltaic devices: organic solar cells.

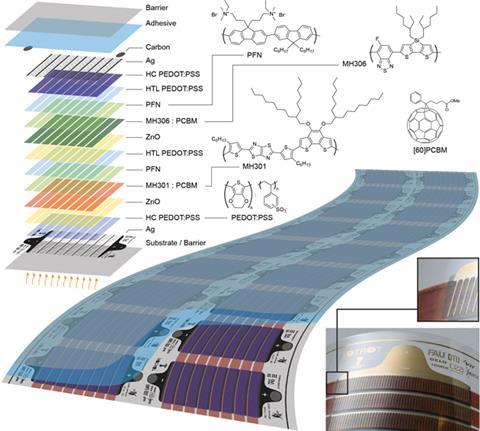

Also known as organic photovoltaic (OPV) cells, these cutting-edge solar cells are gaining attention for their high performance, exceptional light absorption, and remarkable versatility. Their lightweight, flexible design and energy-efficient manufacturing process make them particularly attractive for commercialization.

OPV is a rapidly emerging photovoltaic (PV) technology, offering continuous improvements in cell efficiency (currently 18.2% certified) and an impressive performance lifetime of over 10 years unencapsulated. It also shows strong potential for roll-to-roll manufacturing through solution processing.

The building-integrated PV market may find OPV particularly appealing due to its customizable absorber colors and the ability to produce efficient transparent devices.

Unlike traditional crystalline solar cells, which use silicon as an absorber, organic solar cells rely on carbon-based materials like polymers or small molecules in organic electronics. This allows for the creation of lightweight, flexible, and ultra-thin solar cells that are more durable and can cover larger surface areas than traditional solar cells.

Despite these structural differences, organic solar cells generate electricity using the same photovoltaic effect as monocrystalline and polycrystalline silicon solar cells.

Both organic solar cells and traditional silicon cells have similar structures. The main difference is the material used as the organic semiconductor (OSC). Traditional solar cells use crystalline silicon, while organic solar cells feature a thin-film active layer of carbon-based compounds on top of plastic.

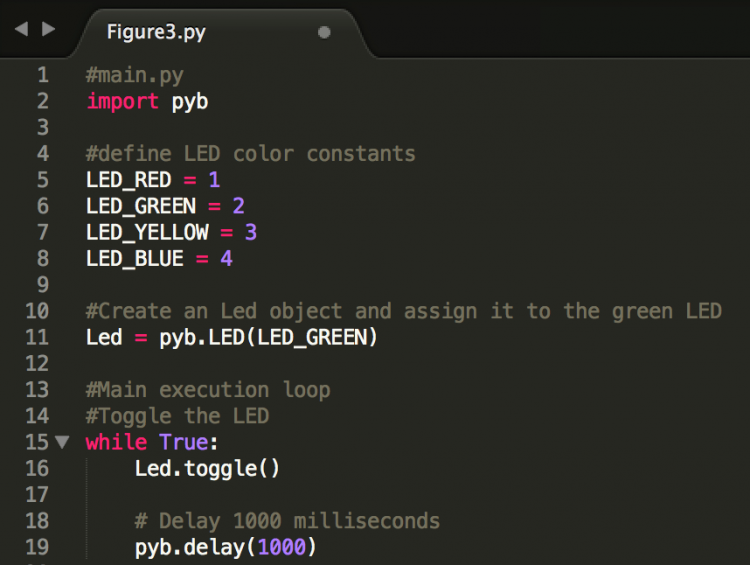

The top contact layer of a solar cell should be made from the most robust material for long-term durability. This makes structure-inverted (n-i-p) solar cells a more stable option, though their power conversion efficiency still lags behind conventional designs. Researchers have identified ways to enhance the performance and stability of these structurally inverted organic solar cells.

One challenge in these devices is the bottom contact, which is typically made from metal oxides like zinc oxide. This creates a narrow recombination area, leading to photocurrent loss. However, applying a thin, solvent-processed silicon oxide nitrate (SiOxNy) passivation layer on the bottom contact eliminates this recombination area, significantly improving efficiency.

Scientists have developed high-efficiency organic solar cells, achieving over 18% efficiency in controlled conditions. However, this is still lower than silicon solar technology, which reaches real-world efficiencies of up to 23%. Despite this, OPV technology holds great promise, enabling surfaces like windows, cars, and buildings to effectively generate solar power.

This information was sourced from eeNews Europe and SolarReviews. Additional resources on OPV technology can be found on Google.