TI introduced two new buck converters and an LDO linear regulator at APEC 2022 that address design challenges for automotive and industrial systems.

Texas Instruments (TI) will launch three new power ICs and address power-management design challenges for electric vehicles (EVs) and industrial systems at the Applied Power Electronics Conference (APEC) 2022. The new products include the LMQ66430 and LMQ66430-Q1 buck converters and TPS7A94 low-dropout (LDO) linear regulator.

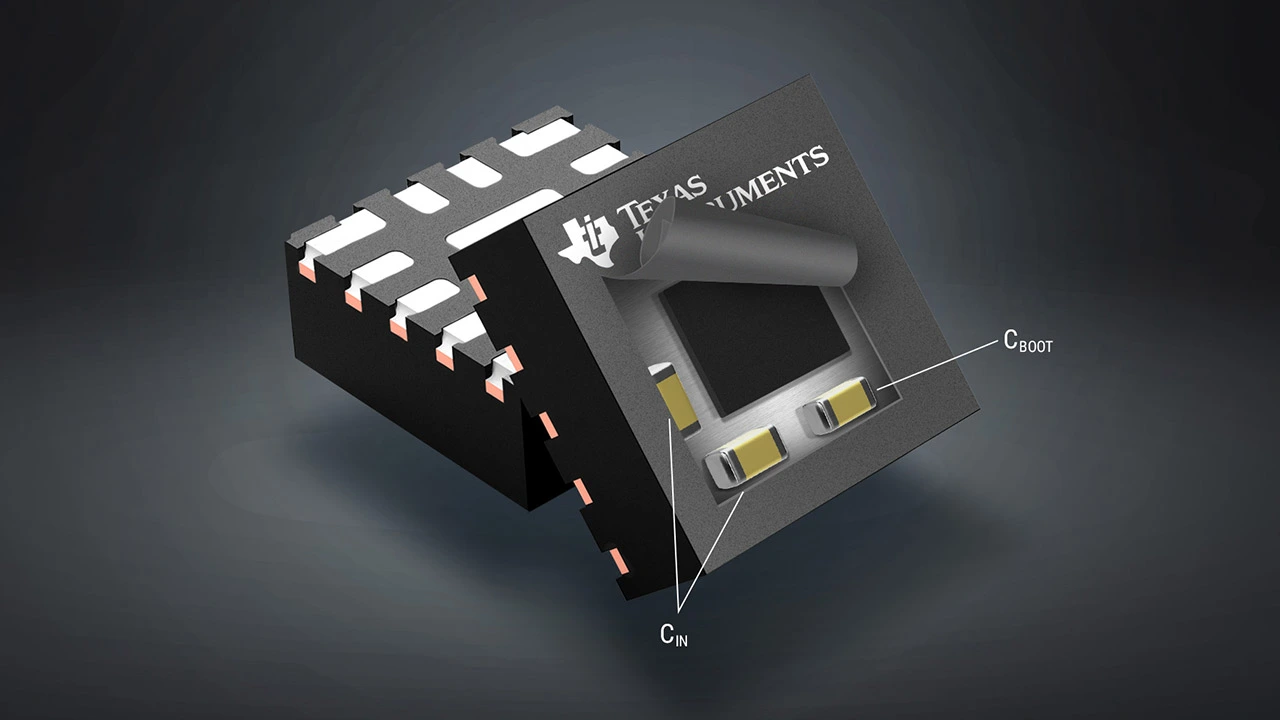

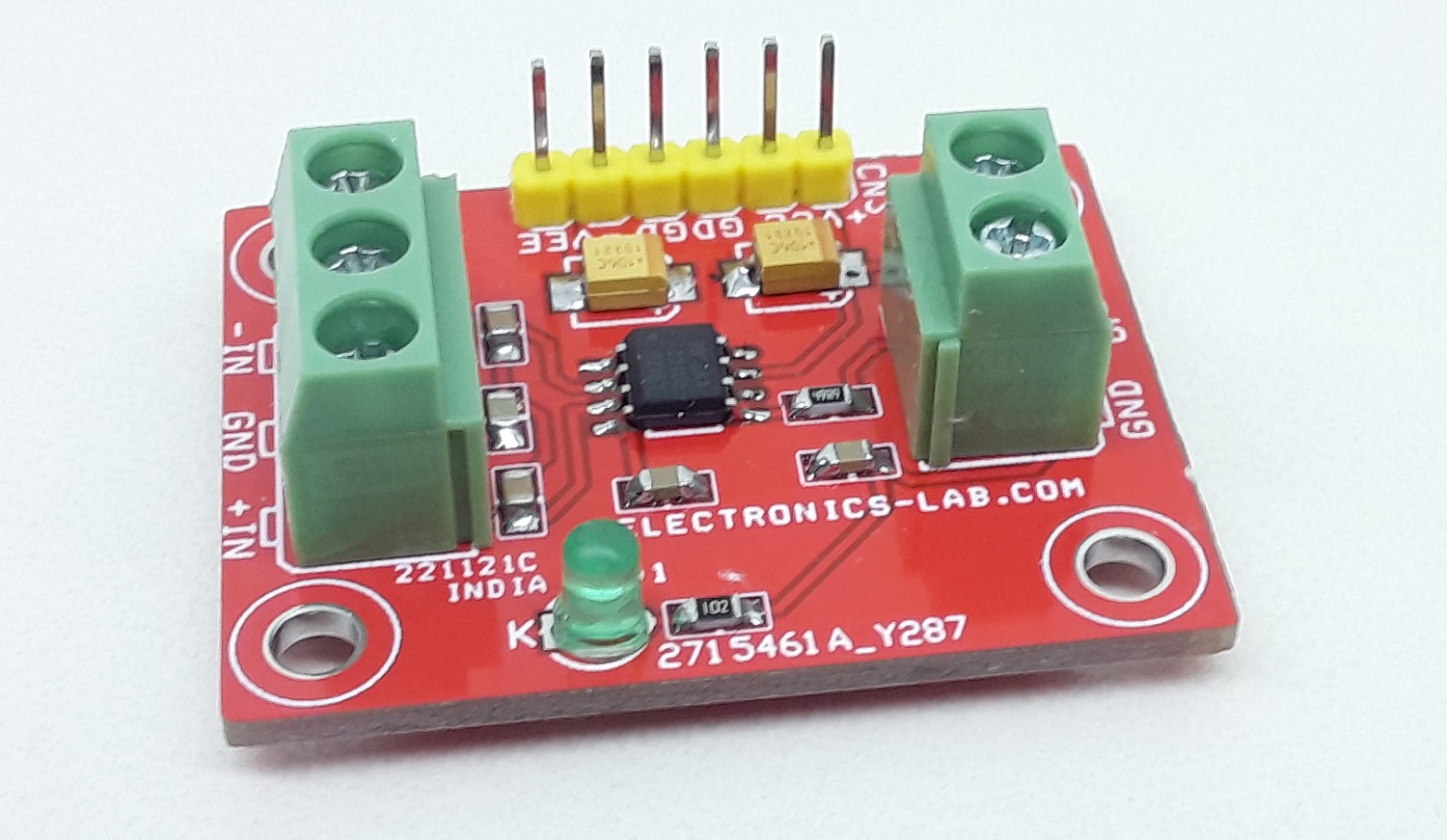

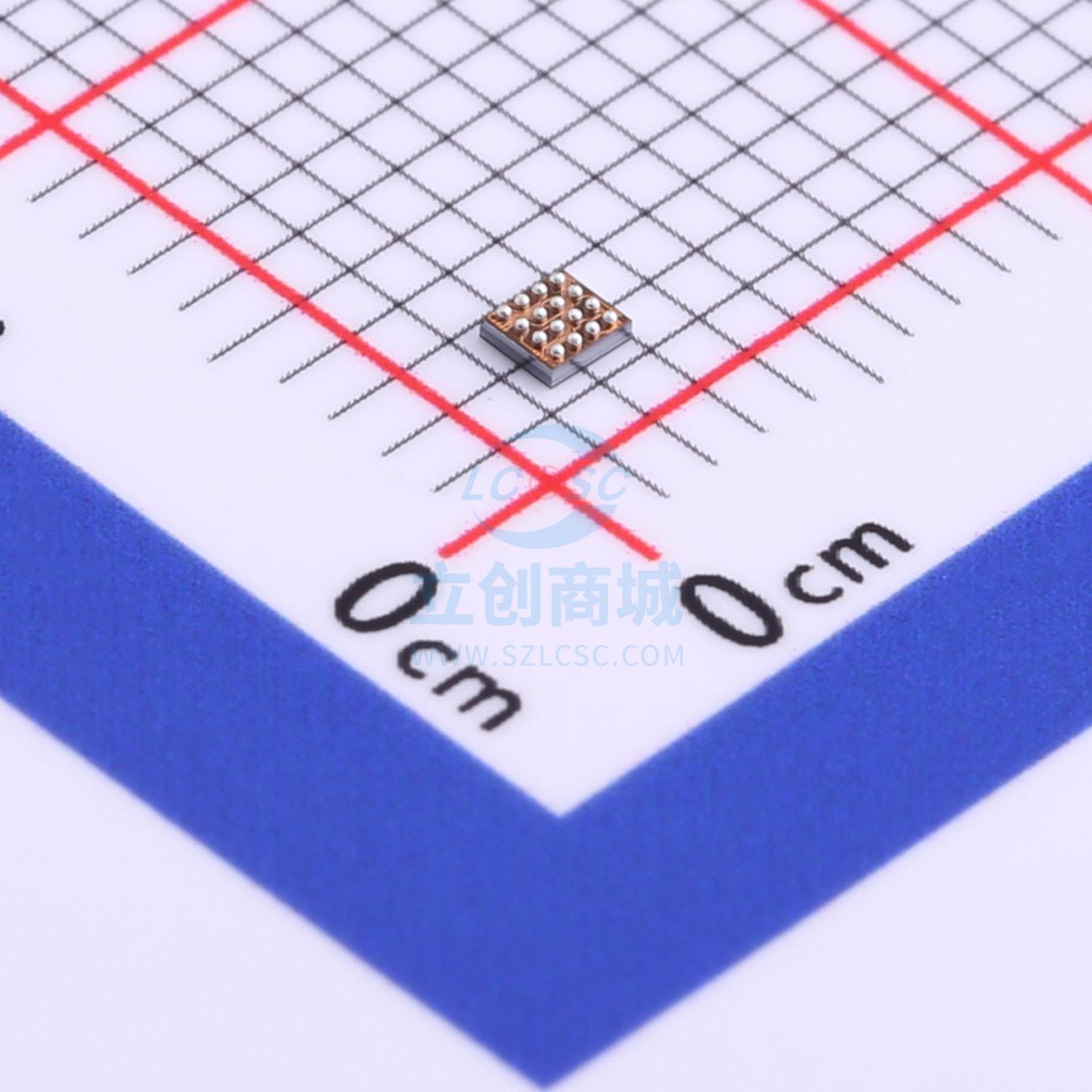

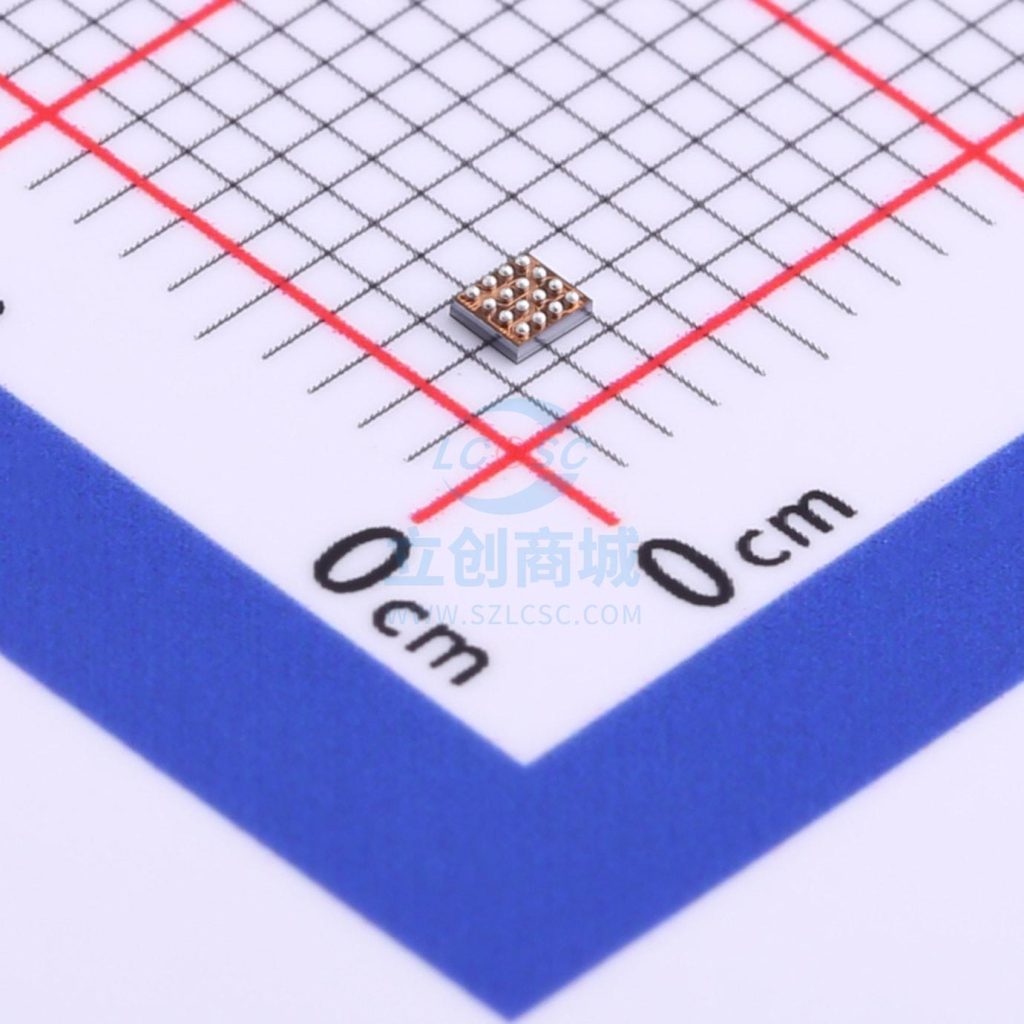

The new 36-V, 3-A LMQ66430 and LMQ66430-Q1 buck converters are designed to lower electromagnetic inductance (EMI) in automotive and industrial applications while improving filter size. The devices integrate two input bypass capacitors and one boot capacitor. This enables engineers to meet Comité International Spécial des Perturbations Radioélectriques (CISPR) 25 Class 5 EMI standards while claiming a best-in-class total solution size of of 114 mm2, 1.5-µA quiescent current (IQ), and reduced bill-of-materials costs.

By integrating the three capacitors in a 2.6 × 2.6-mm enhanced QFN package, it allows for a super small solution, and the benefit to customers is a much smaller EMI passive filter, said Carsten Oppitz, vice president and general manager, buck switching regulators at TI.

“By integrating the bypass capacitors very close to the die, we are reducing the internal inductance, which means we have very little overshoot in the switching,” he said. “This eliminates the interference where it’s usually produced. This means we don’t have to filter so much compared to a standard solution where there is a big passive filter that leads to increased weight of the system and increased size of the system.”

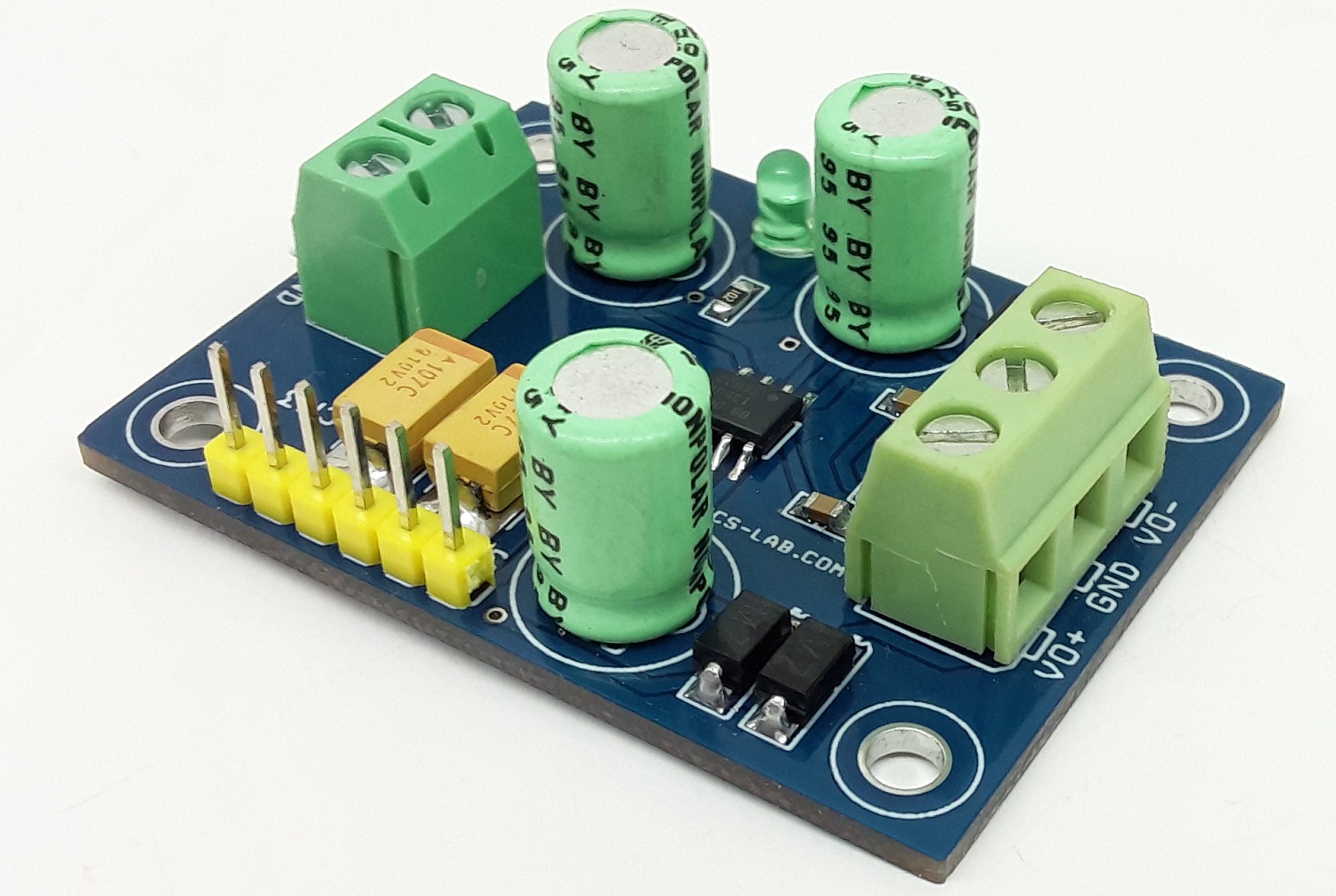

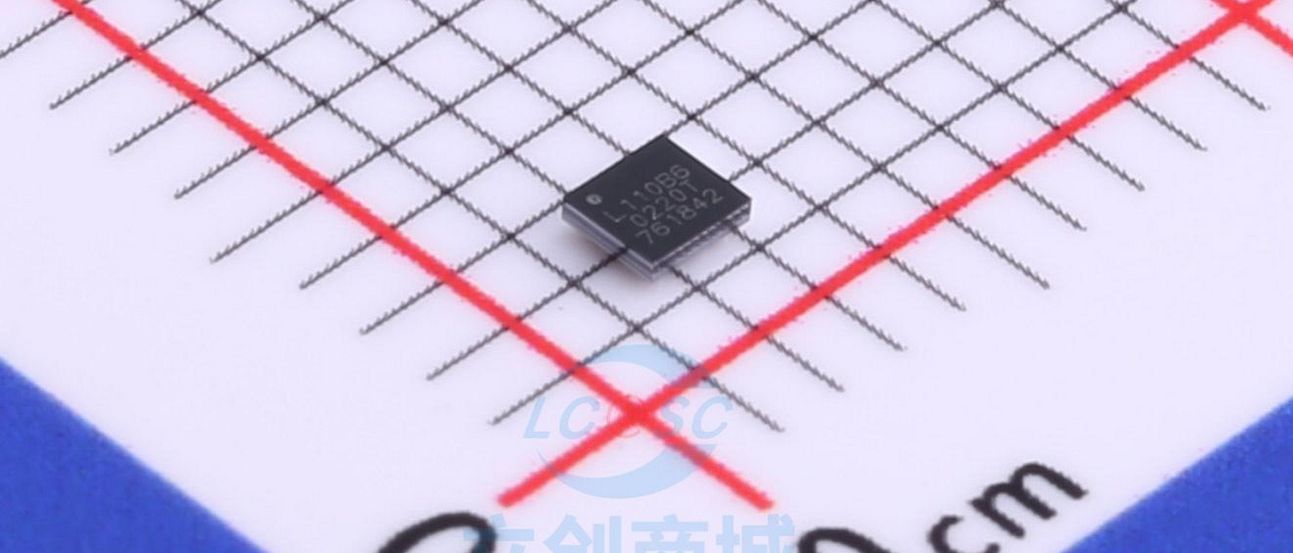

Designed to enhance the power and signal integrity of low-voltage devices thanks to its low noise, the TPS7A94 LDO linear regulator claims the industry’s lowest noise of 0.46 µVRMS – at least 42% better than competing solutions – with a high power-supply rejection ratio (PSRR). This helps designers improve system accuracy and precision in highly sensitive applications.

“Low noise is especially critical in certain types of high-precision analog systems. This includes test and measurement, medical, and telecom applications that really require a very clean power rail,” said Alex Chin, vice president and general manager, linear power at TI.

“Even a small amount of noise can have a negative effect on the performance of noise-sensitive circuits. So, for example, think about server and telecom applications, they’re evolving to accommodate more users and to keep up with more demand for precise signals and even higher date capacity,” said Chin. “Without super-low-noise power rails, the next generation of communication systems will fail to increase the channel density and even the data rates needed to accommodate the increase in both the number of connected devices and the data that each consumes.”

One of TI’s newest devices, the TPS7A94, offers the lowest noise for high precision and high accuracy applications, he said. “With the TPS7A94 we’re adjusting two main noise sources of a power rail. The first one is driving the inherent noise generated by the LDO down to industry leading levels, while also providing amazing PSRR performance to clean up the noise coming from the upstream power supply.”

“The inherent noise from the TPS7A94 LDO is at the industry’s best at 0.46 µVRMS from 10 Hz to 100 kHz and we’re at least 42% better than competing solutions,” said Chin. “Secondly, we’ve also provided 100 dB of PSRR at 1 kHz, while also achieving more than 60 dB at 1 MHz to filter out the upstream power supply. We do this while also providing the solution with a very low dropout making it the most efficient LDO with a typical dropout of 150 mV at 1 A.

Chin also noted the TPS7A94 does not require additional filtering components, which makes the design smaller and more cost-efficient.