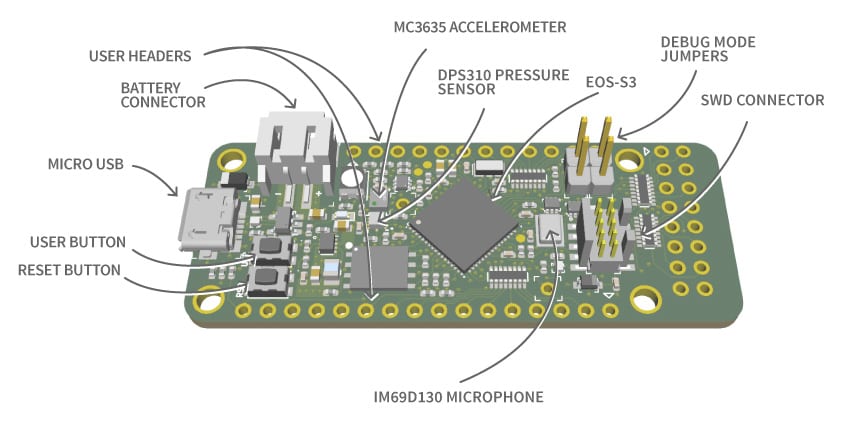

QuickLogic Corporation and Antmicro jointly-announced QuickFeather™, a small form factor development board designed to enable the next generation of low-power Machine Learning (ML) capable IoT devices. On top of the open source hardware design, available on GitHub today, Antmicro has also added support for the QuickFeather board in the Zephyr Real Time Operating System (RTOS) as well as in its open source Renode simulation framework.

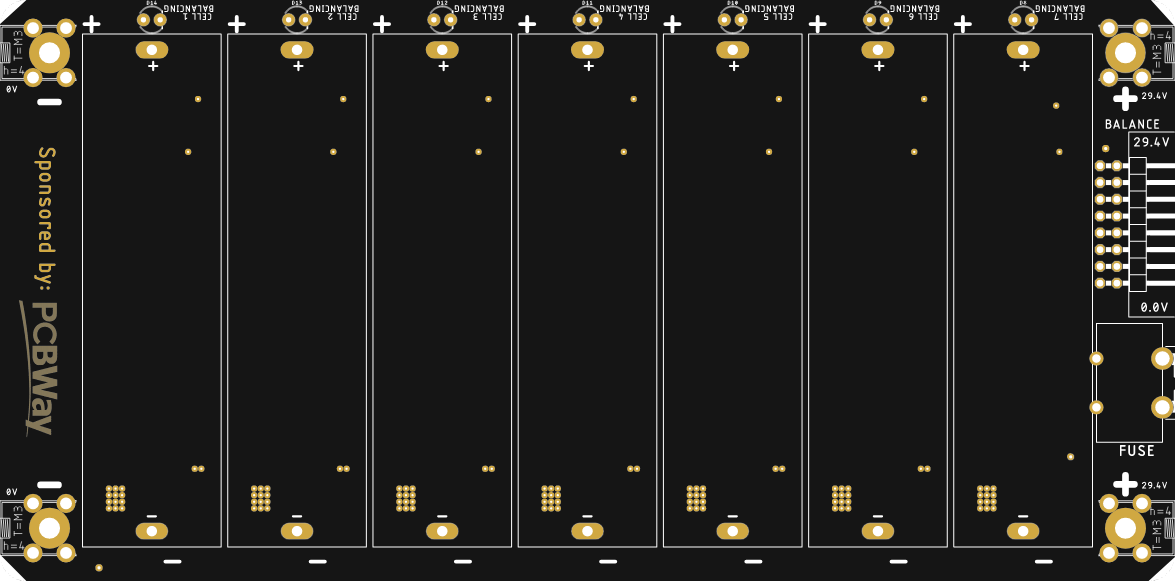

The QuickFeather board is powered by QuickLogic’s EOS™ S3, the first FPGA-enabled SoC to be fully supported in the Zephyr RTOS, with flexible eFPGA logic integrated with an Arm Cortex®-M4F MCU and functionality such as:

- 16-Mbit of flash memory

- MC3635 accelerometer

- Infineon DPS310 pressure sensor

- Infineon IM69D130 PDM digital microphone

- User button and RGB LED

- Powered from USB or a single Li-Po battery

- Integrated battery charger

- USB data signals tied to programmable logic

The QuickFeather development board was created to give developers a powerful and effective way to explore the functionality of the EOS S3 platform and enable compatibility with extensions available for the Feather PCB format from Adafruit, recently also added as a Zephyr Project member.

As announced in late 2019, the EOS S3 is supported in Antmicro’s Renode open source simulation framework for rapid prototyping, development and testing of multi-node systems, offering a more efficient hardware/software co-design approach. Utilizing Renode gives developers the flexibility and functionality to fully evaluate the QuickFeather development board across a number of deployment and configuration scenarios with or without access to hardware.

“An open hardware development board for a cost effective, FPGA-enabled SoC platform coupled with useful sensors, supported in a mainstream open source RTOS and the open source Renode simulation framework, QuickFeather is ideally positioned for use in tiny ML applications such as SensiML’s AI Software Platform and Google’s TensorFlow Lite,” said Michael Gielda, vice president of business development at Antmicro. “We are proud to be helping QuickLogic build an open hardware and software ecosystem that can serve as a model for the entire industry.”

“Machine learning applications are being deployed at an amazing rate and the new QuickFeather board will further accelerate that trend,” said Brian Faith, president and chief executive officer of QuickLogic. “Developers love the fact that it and its associated Renode simulation framework are open source, making it even more attractive for implementing ML algorithms on endpoint IoT applications.”

Availability

The QuickFeather board with integrated EOS S3 voice and sensor processing SoC, and the Renode simulation environment are all sampling now and will be available in early Q2.