HEY is an innovative bracelet that really makes you feel connected to a loved one. It uses a unique technology to send your touch as far as needed. It’s the first bracelet that mimics a real human touch, not by producing a mechanical vibration or buzzing sensation, but an actual gentle squeeze.

On Valentine’s Day the stylish piece of smart jewelry was launched on Kickstarter and within one hour it was already ‘trending’. Check the campaign video:

On Valentine’s Day the stylish piece of smart jewelry was launched on Kickstarter and within one hour it was already ‘trending’. Check the campaign video:

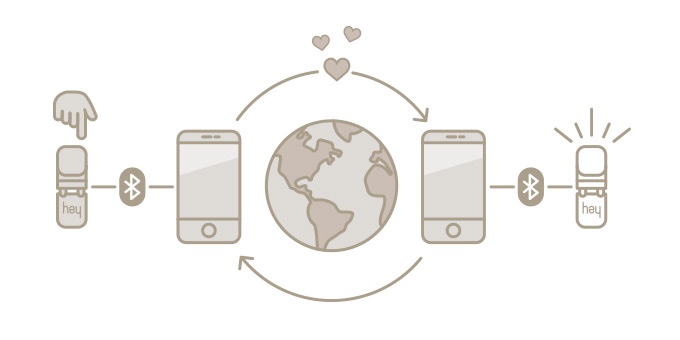

The bracelet incorporates advanced technology that communicates through Bluetooth with your smartphone. The ingenious design ensures that a touch wouldn’t be sent accidentally. In order to send a message you should touch the bracelet in two places and it will be transferred directly to your phone and from there to the connected HEY bracelet anywhere in the world.

“Via Bluetooth HEY is connected to an app on your smartphone. This app makes sure all your little squeezes reach the other bracelet directly. It also helps you pair the bracelets easily, fast and without any hassle. And last but not least it keeps track of your love stats. For instance the distance between you and your loved one or the last time you were together. If desired, these features can be turned off. In the future more features will be added to the app.”

HEY is invented by Mark van Rossem. He looked at the current world of communication and saw that one thing was missing. And that thing was touch. People communicate through technology 24/7, but there is always a physical distance separating them. So Mark set himself the seemingly impossible goal to send touch at great distances and came up with the idea for HEY. Together with successful entrepreneur, David van Brakel, he gathered a team of creative and technical professionals that have all earned their credentials in their field of expertise. Together they want to build products that bring people closer.

“From a simple touch like squeezing someone’s hand, to hugging, social touch is important in the way we maintain healthy and happy social relationships with the people that we care about most.” – Gijs Huisman, who collaborated in developing bracelet, is an expert at the University of Twente in the field of Social Touch Technology and has been researching haptic technology (touch by tech) for five years now.

No need to worry a lot about the safety of the bracelet electronics since the design is weatherproof. With only 30 minutes of charging, you will be able to send touches for around 3 weeks!

HEY adds a completely new dimension to relationships and more haptic products will be developed in the near future. For more information and updates, check the official website and the Kickstarter campaign. 35 days are left to pre-order 2 HEY bracelets with the Kickstarter deal for €83 which is 30% of the retail price.

The product is available for $150 on

The product is available for $150 on