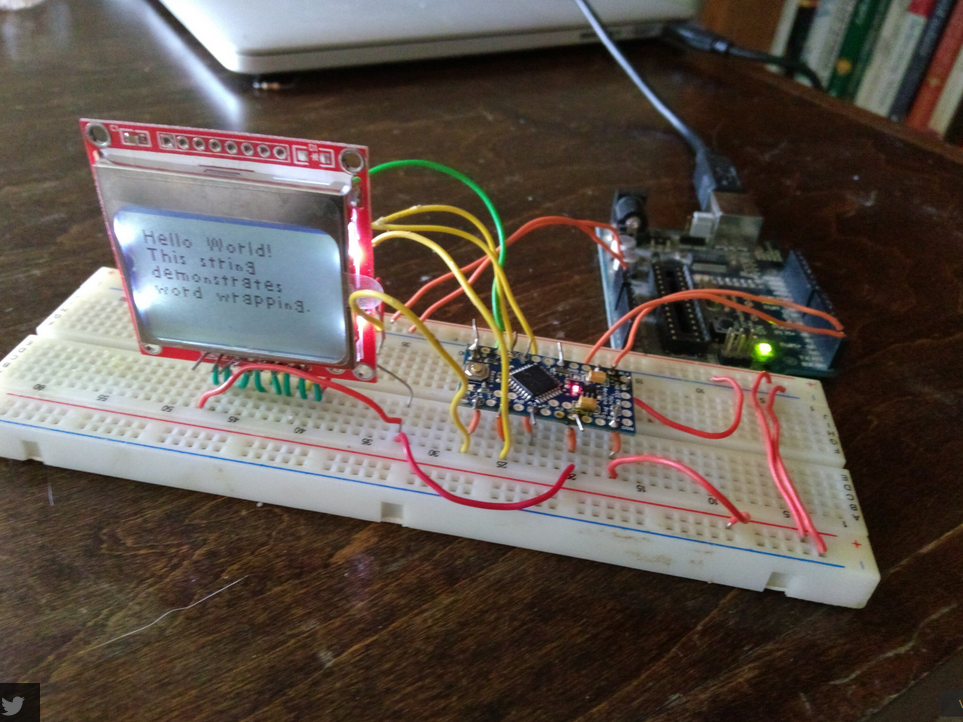

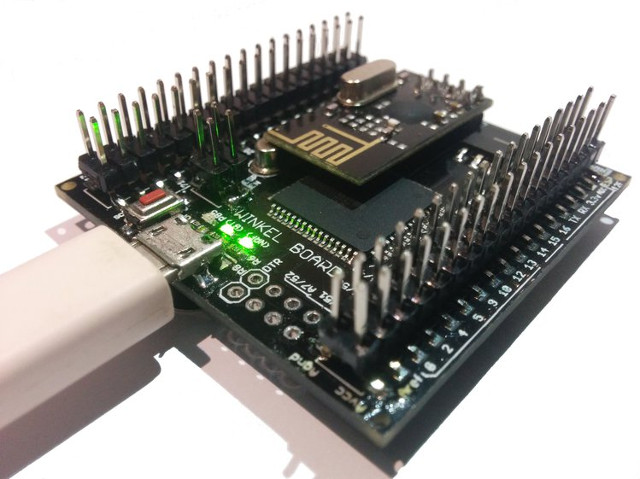

Mintbox Technologies is an Indian tech startup who build smarter connected devices for everyone. It is specialized in consumer electronics, open source software & hardware, PCB design services. Mintbox latest product is The Winkel Board, a powerful new Arduino-compatible, open source hardware platform for development and prototyping.

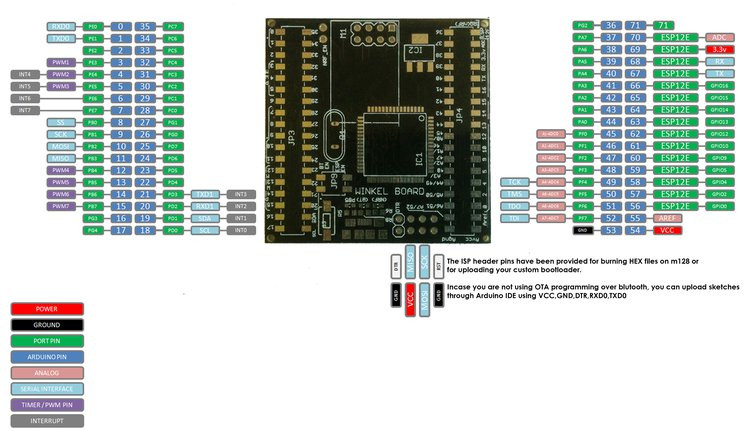

Based on the Atmel ATmega128 microcontroller, The Winkel Board is designed to be easy to use for both junior and senior makers including many popular peripherals such as WiFi, radio, and Bluetooth on board.

Check this video to know The Winkel Board features:

By providing an all-in-one compatible Arduino board, Mintbox team is working to solve the routine each maker does before starting a project, which they clarify in this list:

TODO for a maker while building something awesome:

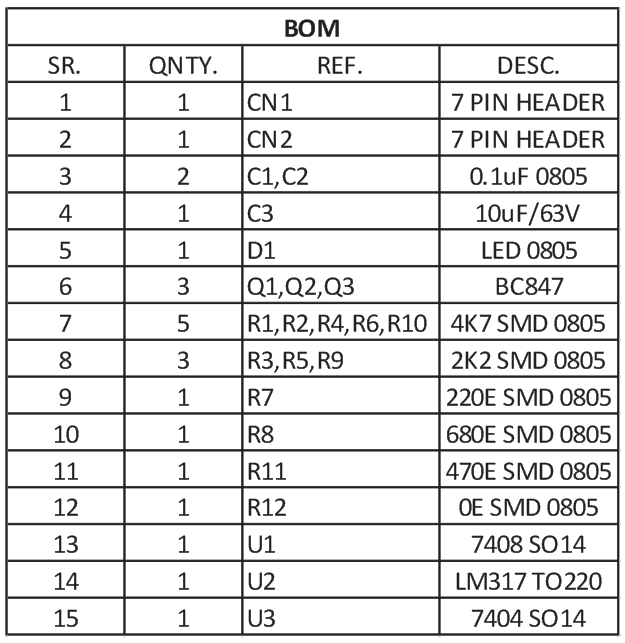

- Prepare a list of right electronics components

- Prepare BOM

- Search them locally or online to fit the BOM

- Wait for the components to arrive if sourced online

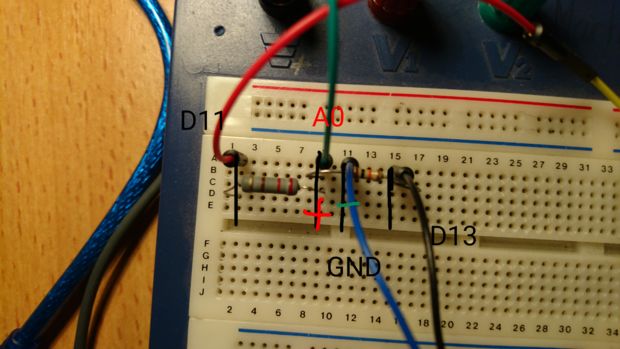

- Getting started with prototyping

- Go online again studying libraries and figuring out how they can be interfaced on breadboard or etch a PCB

- Finally start building and actually working on your project and then try not to rage quit

The Winkel Board specifications

- MCU – Microchip/Atmel ATmega128 MCU @ 16 MHz with 128KB flash memory, 4KB SRAM, 4KB EEPROM

- Connectivity

- WiFi 802.11 b/g/n via ESP12E module based on ESP8266

- Bluetooth 2.0 + EDR via HC-05 module

- RF Radio – NRF24l01 2.4 GHz ISM radio.

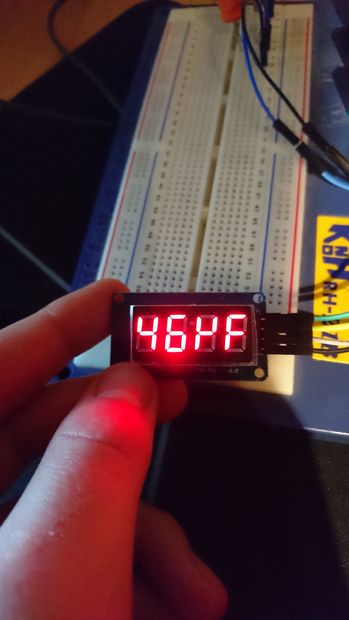

- I/Os (through both Atmel MCU and ESP8266)

- 38x Digital I/Os

- 7x PWM Digital I/Os

- 8x Analog Inputs

- USB – micro USB port for programming and power

- Misc – DS3231 Real-Time Clock + CR2032 battery slot, a few LEDS, reset button, jumper for OTA mode, ISP header, optional MPU-6050 Gyro+accelerometer mount

- Power Supply – 5 V

- Dimensions – TBD

This board is said to be a one stop platform, that combines different communication protocols and allows a lot of I/O operations, thus you can do everything at once or choose specific on-board components to work with.

The Winkel Board is completely open source, you can check Mintbox’s Github once they upload all the source files soon. This board is now live in a crowd -funding campaign, you can pre-order your own Winkel now for around $21.

![Emulate an Apple ][ on an AVR Microcontroller](https://www.electronics-lab.com/wp-content/uploads/2016/12/01-604x270.jpg)

The

The