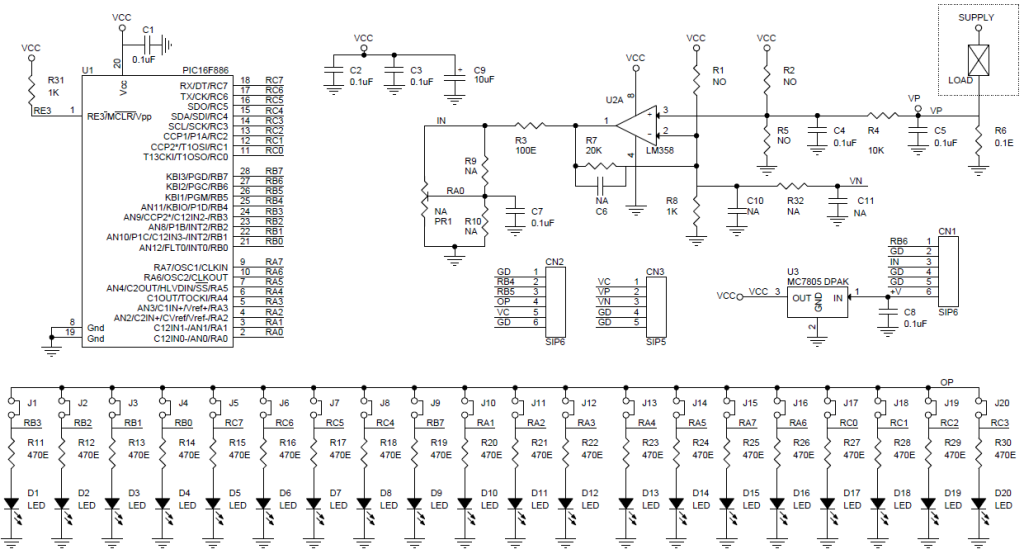

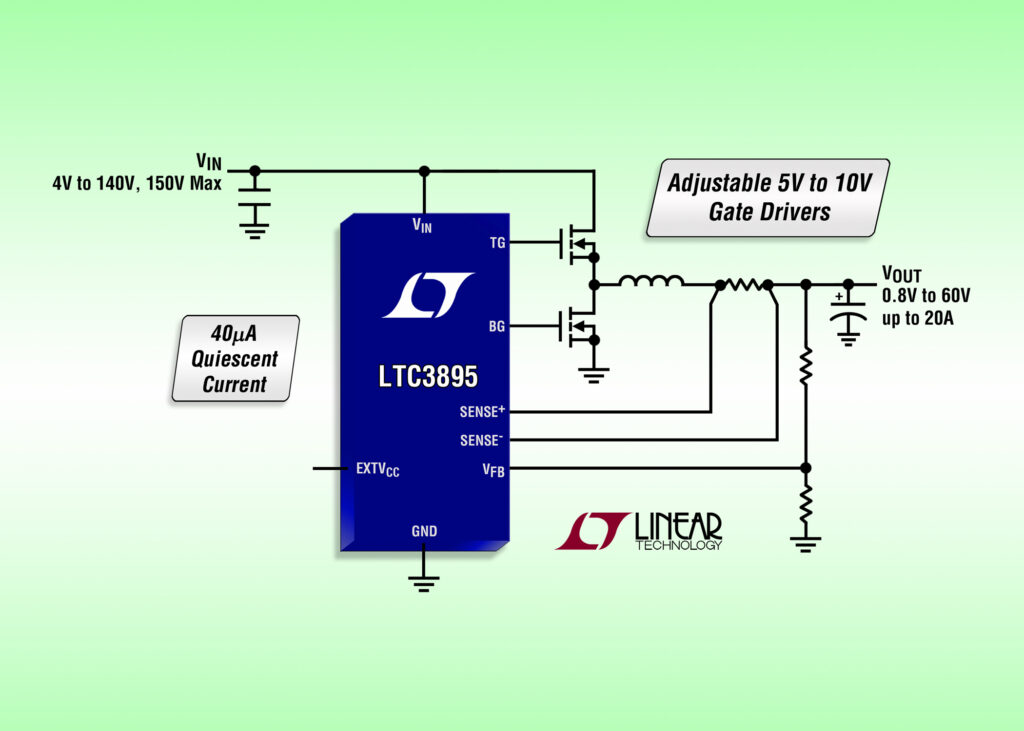

Linear Technology Corporation announces the LTC3895 , a high voltage non-isolated synchronous step-down switching regulator controller that drives an all N-channel MOSFET power stage. Its 4V to 140V (150V abs max) input voltage range is designed to operate from a high input voltage source or from an input that has high voltage surges, eliminating the need for external surge suppression devices. The LTC3895 continues to operate at up to 100% duty cycle during input voltage dips down to 4V, making it well suited for transportation, industrial control, robotic and datacom applications.

The output voltage can be set from 0.8V to 60V at output currents up to 20amps with efficiencies as high as 96%. This part draws only 40μA in sleep mode with the output voltage in regulation, ideal for always-on systems. An internal charge pump allows for 100% duty cycle operation in dropout, a useful feature when powered from a battery during discharge. The

LTC3895’s powerful 1Ω N-channel MOSFET gate drivers can be adjusted from 5V to 10V to enable the use of logic- or standard-level MOSFETs to maximize efficiency. To prevent high on-

chip power dissipation in high input voltage applications, the LTC3895 includes an NDRV pin which drives the gate of an optional external N-channel MOSFET acting as a low dropout linear

regulator to supply IC power. The EXT VCC pin permits the LTC3895 to be powered from the output of the switching regulator or other available source, reducing power dissipation and improving efficiency.

LTC3895 – Step-down controller handles 150 V – [

Link]