In this tutorial, you’ll learn how to burn Arduino bootloader on a new ATmega328 using USBasp ISP programmer. Every Arduino Uno Board comes with a microcontroller called the Atemga328P, and they are already pre-program with Arduino Bootloader firmware. Therefore, there is no need to burn Arduino bootloader into those Atmega328P chips again. Here, we will be focusing on burning the Arduino bootloader on an off the shelf Atmega328 chip so that you could make your own DIY Arduino board or deploy your Arduino-based circuit to a printed circuit board.

NOTE – The bootloader is the little program that runs when you turn the Arduino on or press the reset button. It’s main function is to wait for the Arduino IDE on your computer to send a new program, which then is written to Arduino memory.

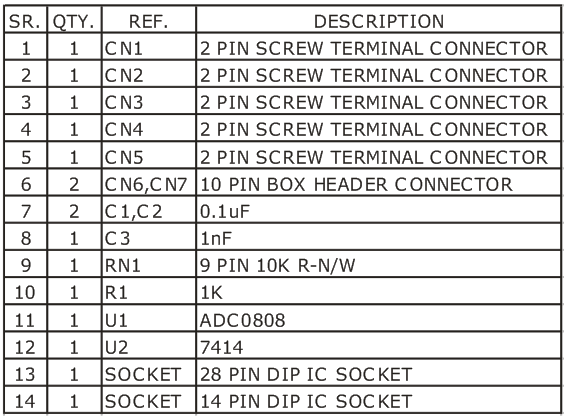

Required components:

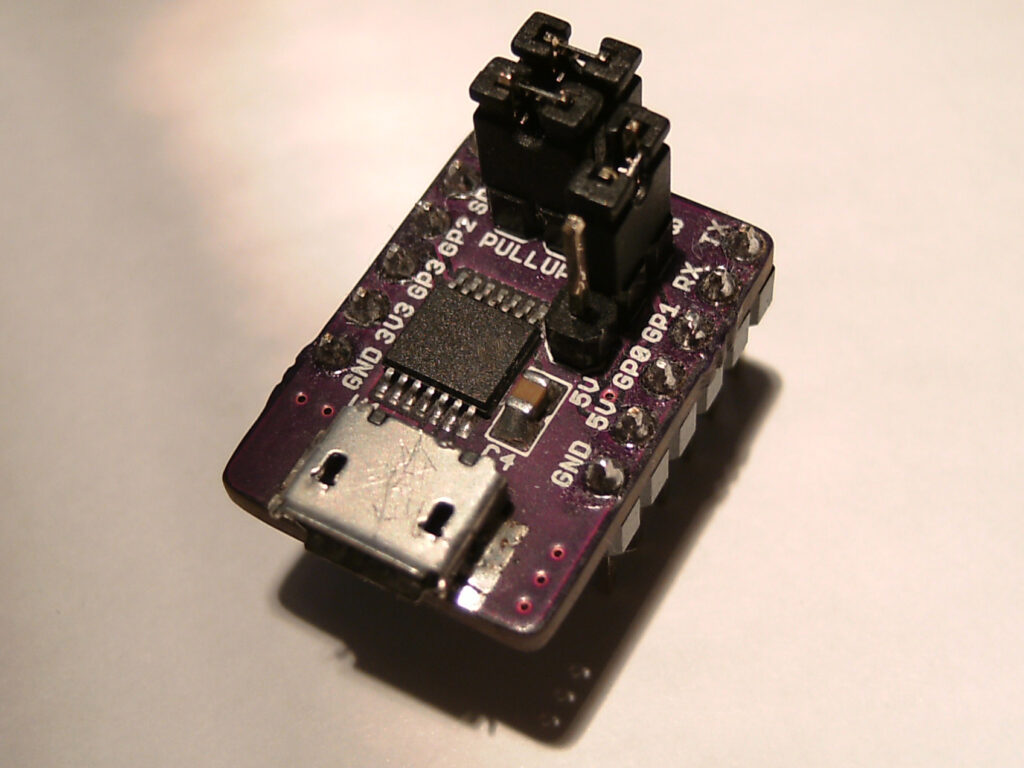

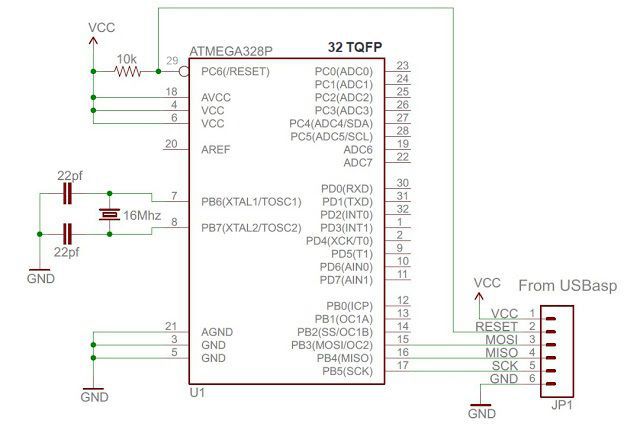

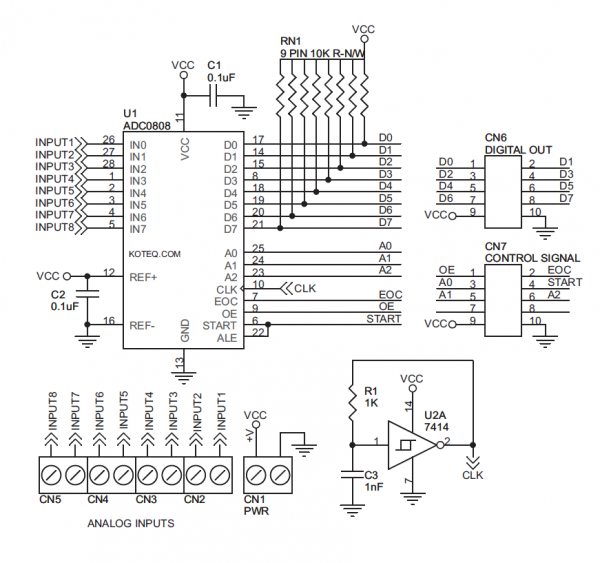

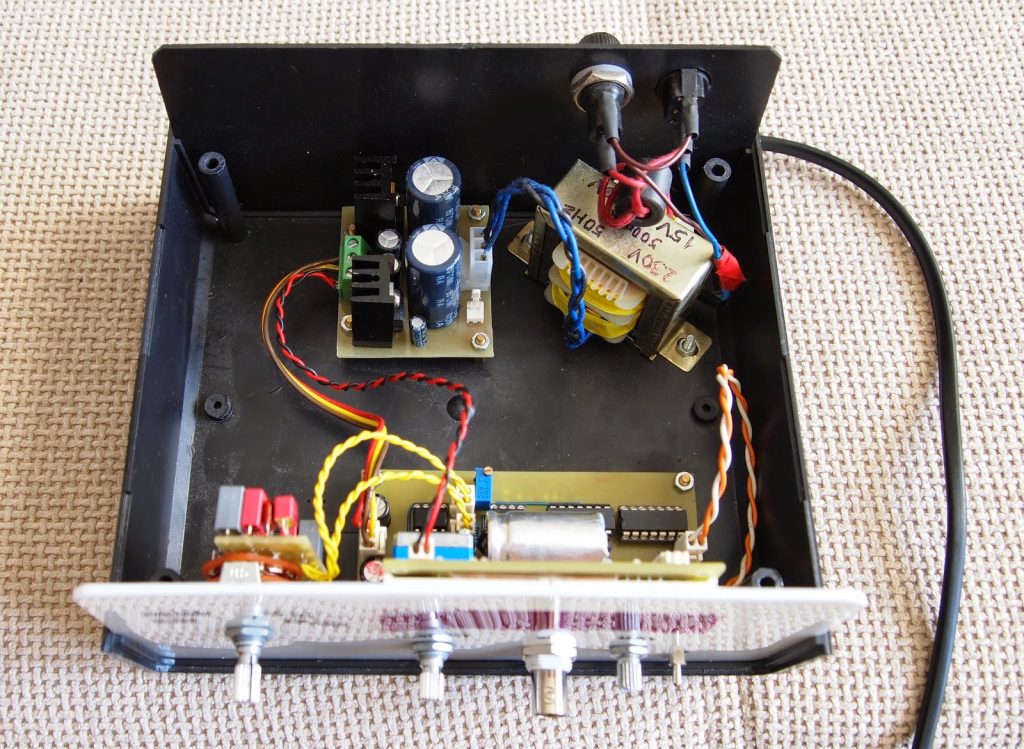

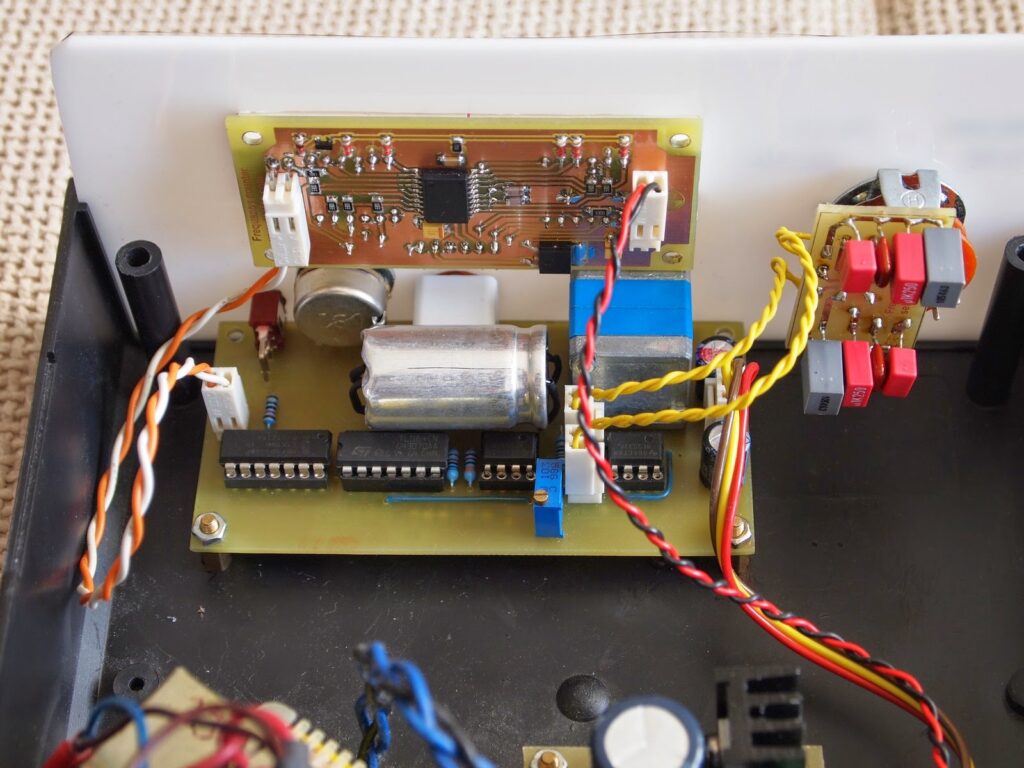

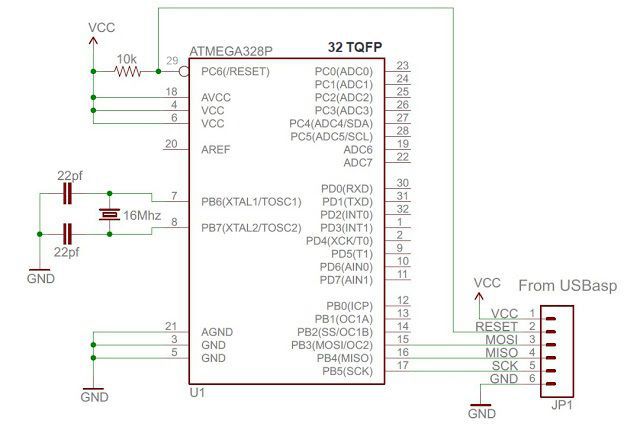

First of all wire up the circuit in the breadboard as shown in the diagram above. Please connect all the connections carefully.

In above circuit JP1 is where USBasp programmer is connected. Connect all the wires carefully as per above diagram using a jumper wire.

Software Install

If you wire up your circuit correctly then it’s time to load hex file which is located in your Arduino software folder. Here is the complete path for Arduino 1.x in windows – C:\Program Files (x86)\Arduino\hardware\arduino\avr\bootloaders\optiboot\optiboot_atmega328.hex you can also download from here optiboot_atmega328

Next, you need to install AVRdude software and USBasp Programmer Driver.

Bootloading

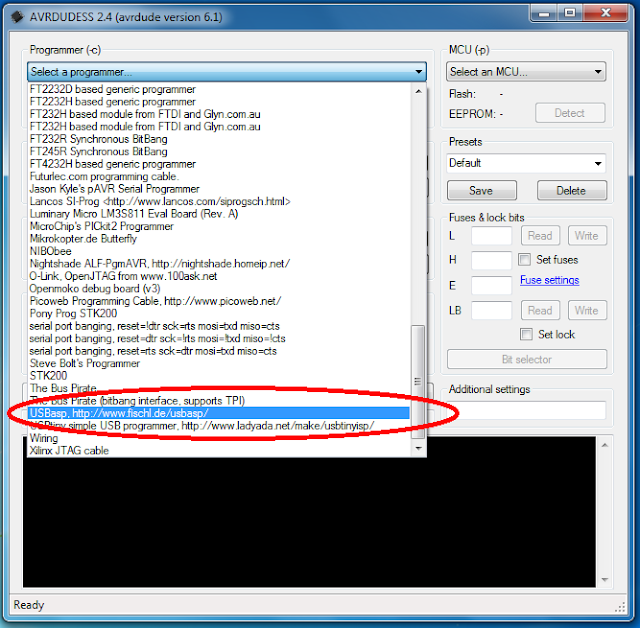

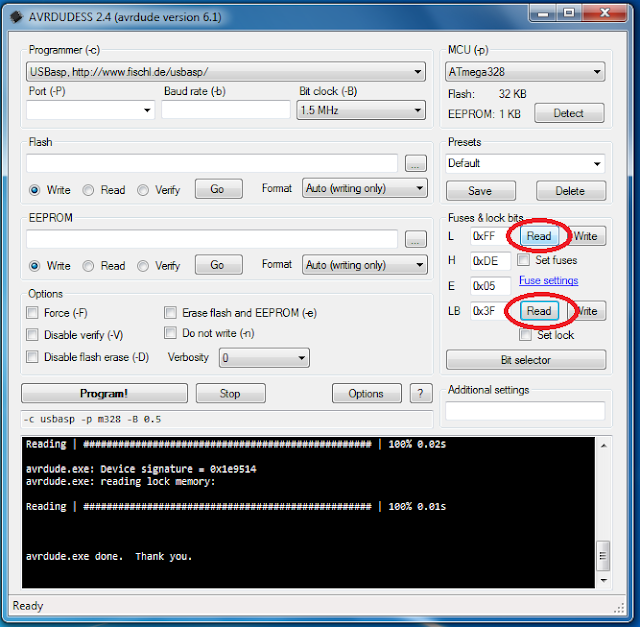

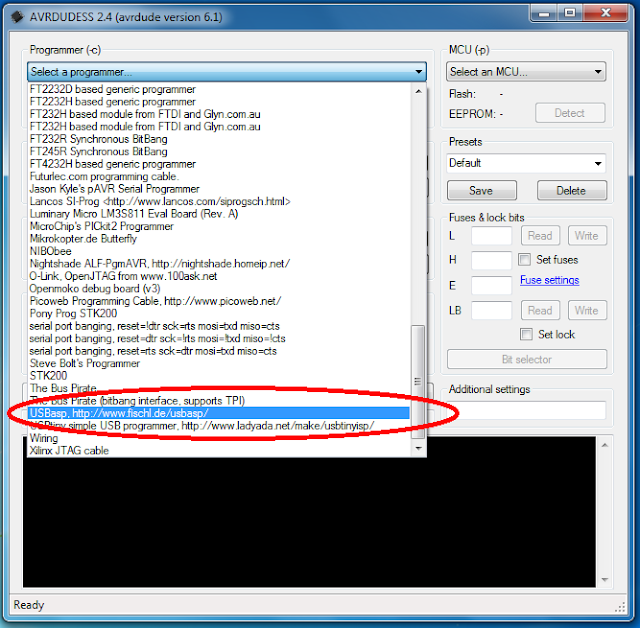

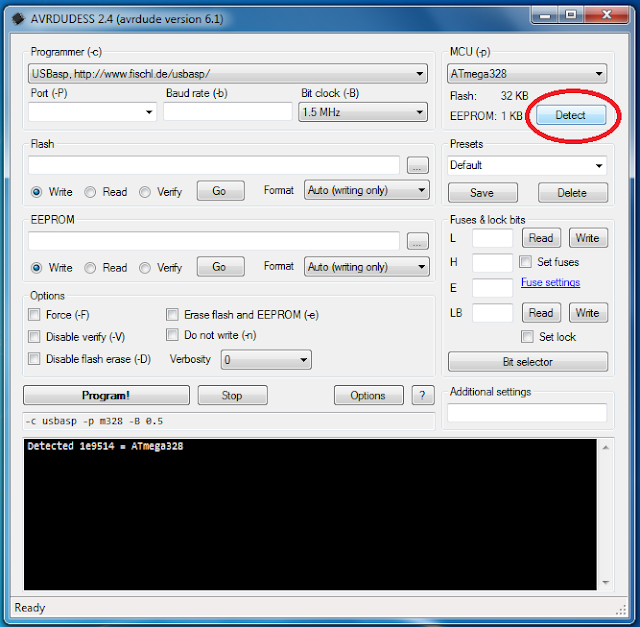

Open the AVRdude software and select programmer type from the drop-down list shown in below image. In our case programmer is the USBasp programmer.

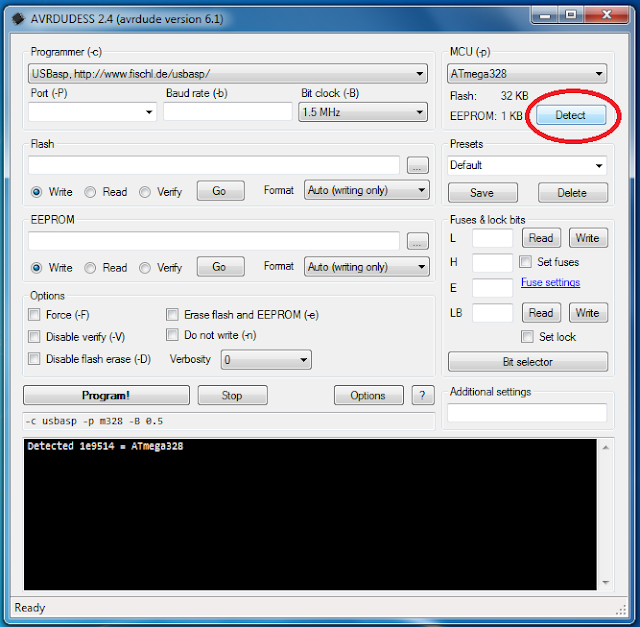

After Selecting programmer type click on “Detect” so programmer automatically detects ATmega328. If you have any problem with detecting microcontroller check all connections carefully.

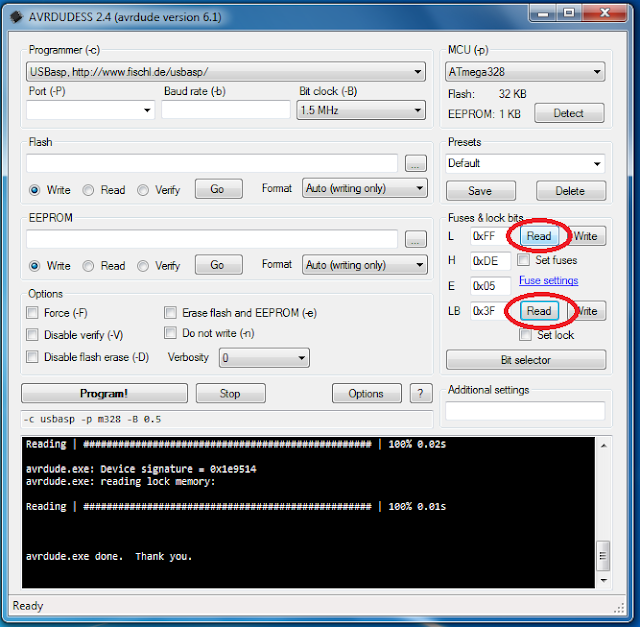

After detecting microcontroller, it’s time to read fuse bits and lock bits. As shown in below screenshot click on “Read.”

Make sure you don’t write wrong fuse bits, otherwise your microcontroller will stop working.

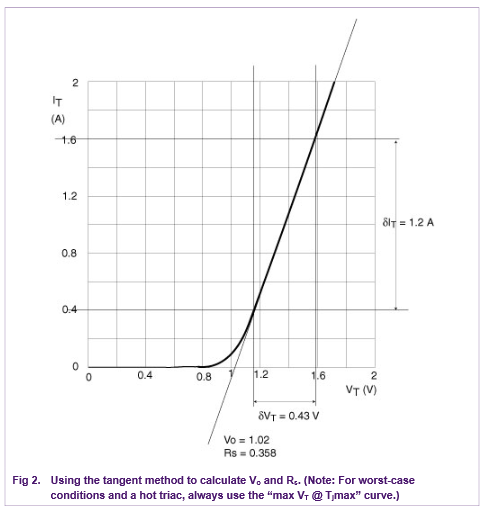

The default value of fuse bit.

- LOW Fuse : 0x62

- HIGH Fuse : 0xD9

- Extended : 0x07

- LOCK :0xFF

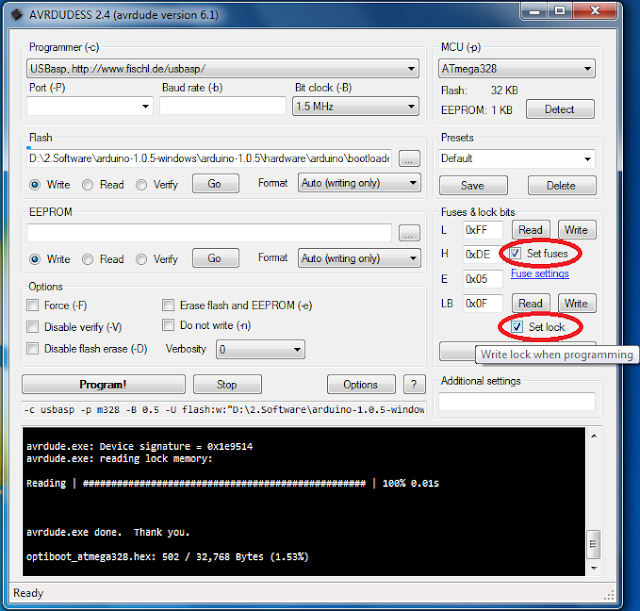

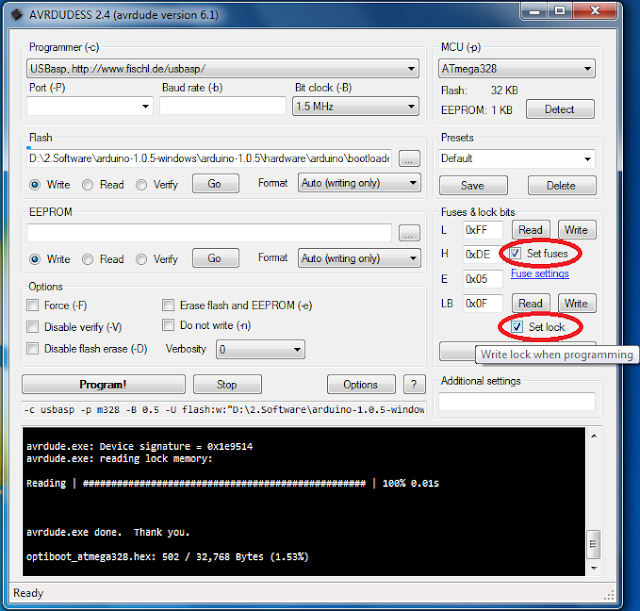

To configure the Atmega328 for use with Arduino Uno boards, set the fuse settings as below:

- LOW Fuse=0xFF

- HIGH Fuse=0xDE

- Extended Fuses=0x05

Under Flash, browse the hex file optiboot_atmega328.hex which you downloaded previously, select the file and click “Open.”

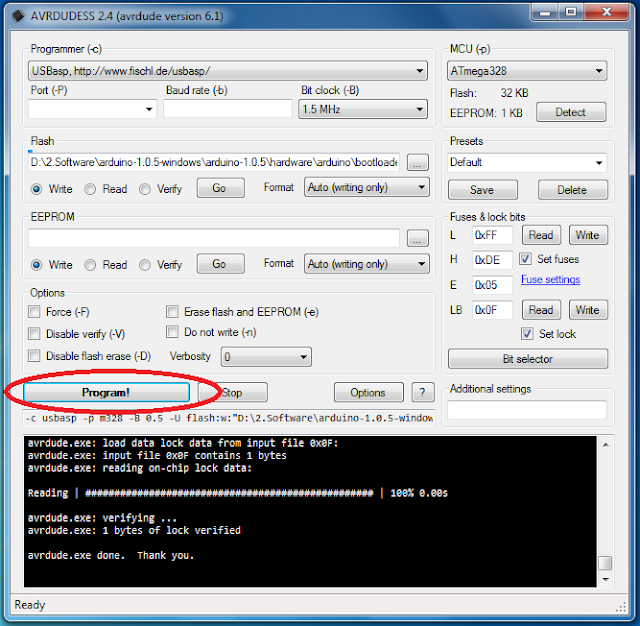

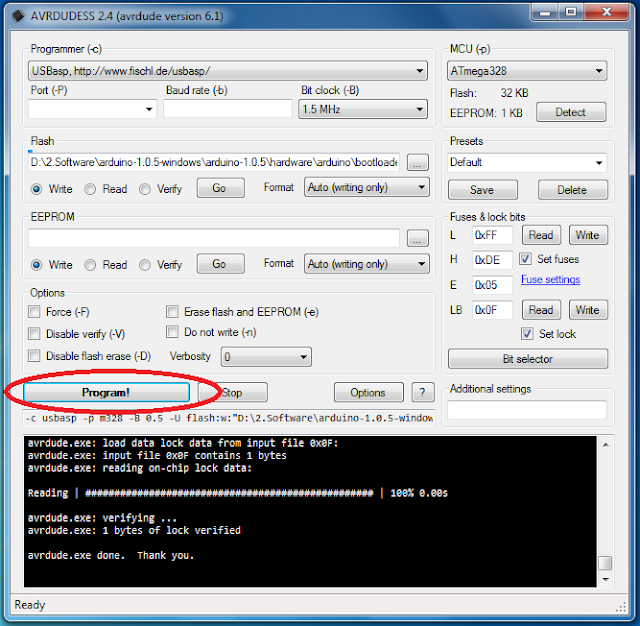

Now click on “Program!” button. It will take about 30 seconds. You can now use your cheap ATMega328 microcontroller as a regular Arduino.

You now have an Atmega328P that can be programmed with the Arduino IDE. Just plug in your new Atmega328P into any Arduino Uno board or using a USB to Serial Converter to upload your Arduino Sketch.

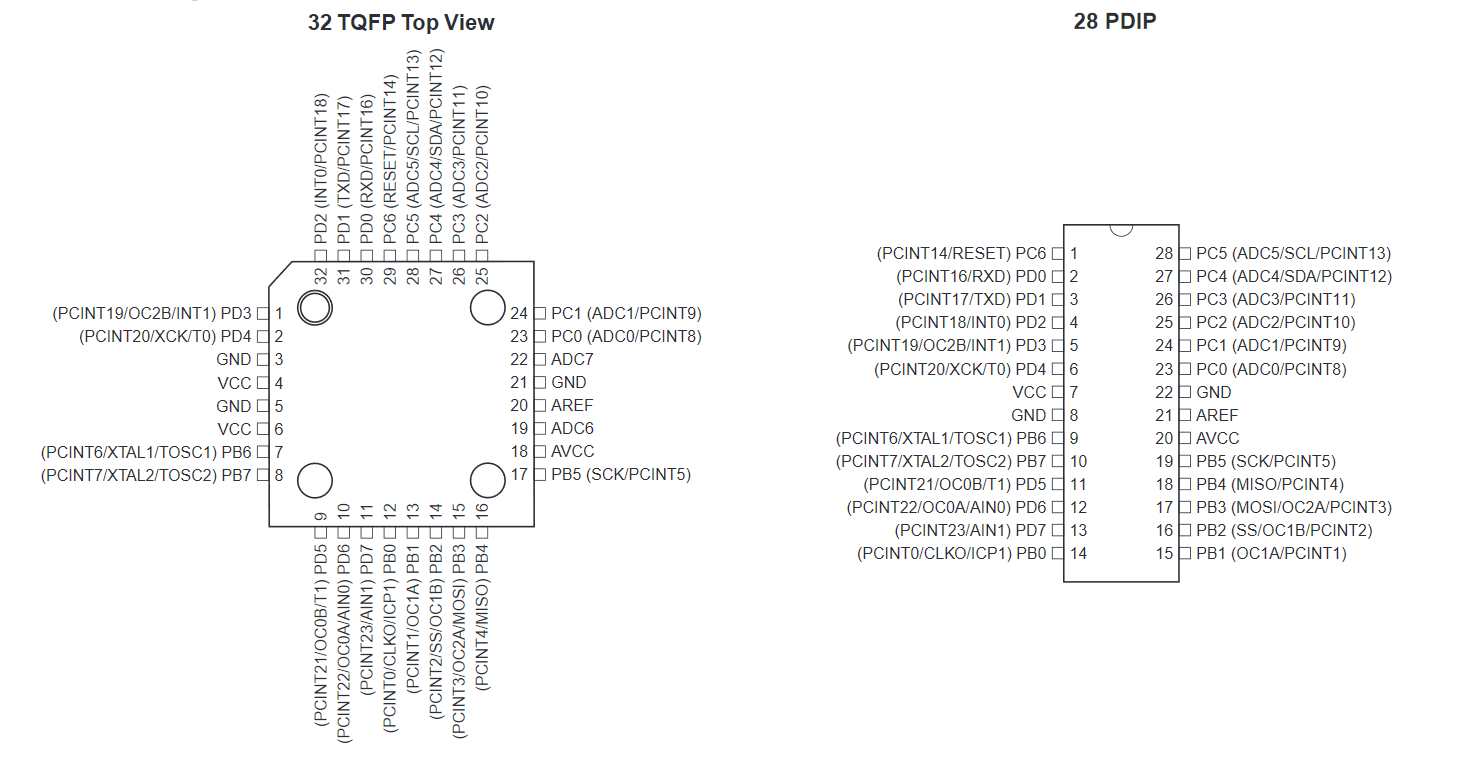

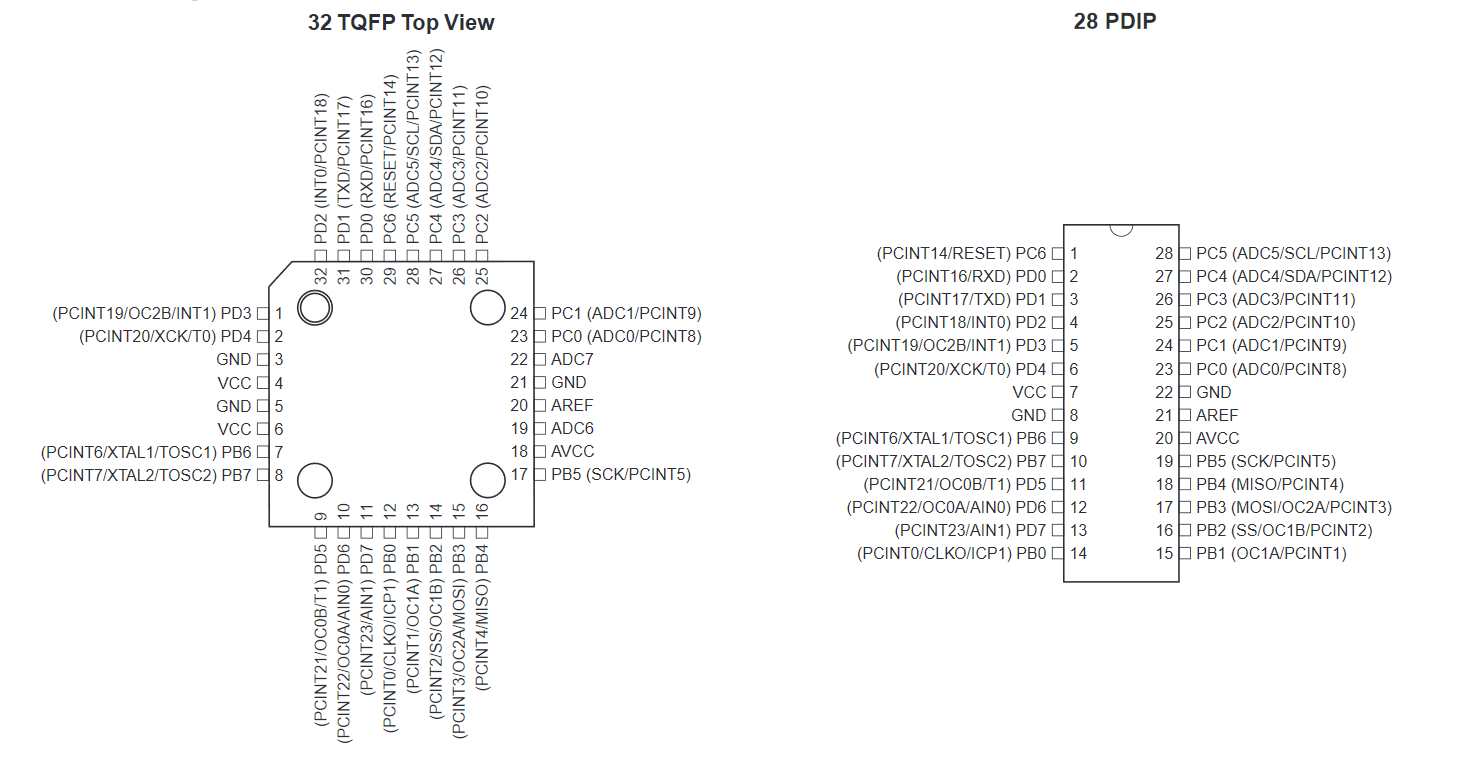

ATMega328 Pinout (TQFP and PDIP)

The schematic at the start of the post is for the 32 TQFP package and you can easily modify it for the 28 PDIP version using the following pinout.

The tutorial’s part list is sponsored by www.lcsc.com, the wholesale retail electronic components store in China. To learn more about LCSC.com read their company profile:

- Who we are: LCSC Electronics is one of the fastest growing suppliers of electronic components in China. LCSC Electronics has been committed to offering multitudinous, genuine and in-stock items, since its founding in 2011.

- Main Products: Our extensive product includes semiconductors, resistors, capacitors, diodes, inductors, connectors, transistors, and sensor.

- Line cards: LCSC purchasing teamwork persistently to select the Chinese trusted manufacturers according to a high standard. We have 72 authorized brands suppliers which are still increasing by time, 173 international brands and 489 Asian brands suppliers.

- Warehouse: LCSC Electronics has a self-owned modern component warehouse with 10,000 ㎡ by stocking more than 180,000 kinds of parts. LCSC’s project of building the Technology Industry Park with an area of 350,000 ㎡ was launched in Jiangsu in July 2018, which provides a solid foundation for the development of stocking and supply chain in the next 5-10 years and it is Asian largest in-store components warehouse.

- Shipping: In-stock orders are ready to be shipped in 4 hours and send out to each corner of the world by DHL, FedEx EMS, USPS, and other carriers.