A new implementation of the AVR DDS signal generator v2.0 found at: http://www.scienceprog.com/avr-dds-signal-generator-v20

Introduction

This is a new implementation of the AVR DDS signal generator v2.0, already published in scienceprog.com. It is obvious that full credit for the original schematic and the firmware goes to its original creator. Presented here is a different PCB that is compact, single sided with only through-hole components for easy construction.

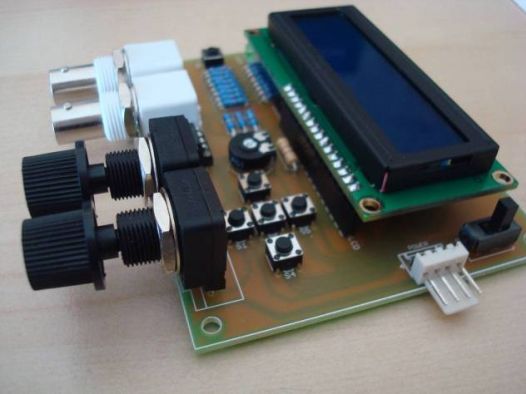

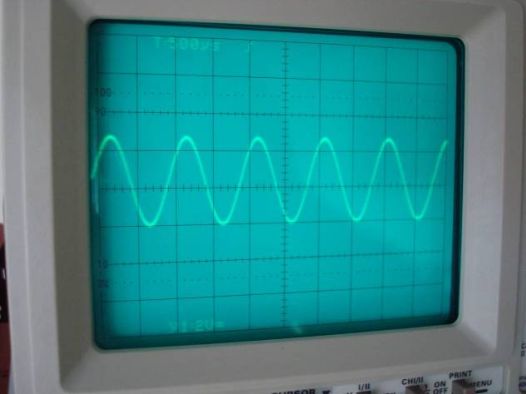

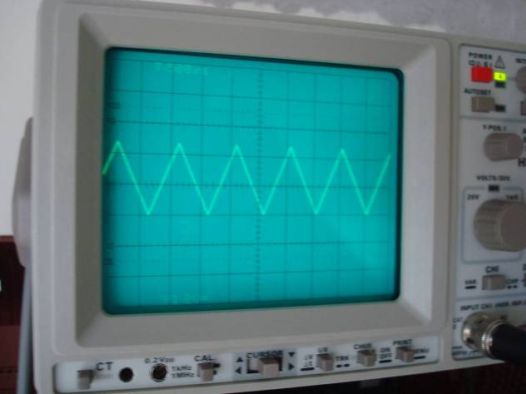

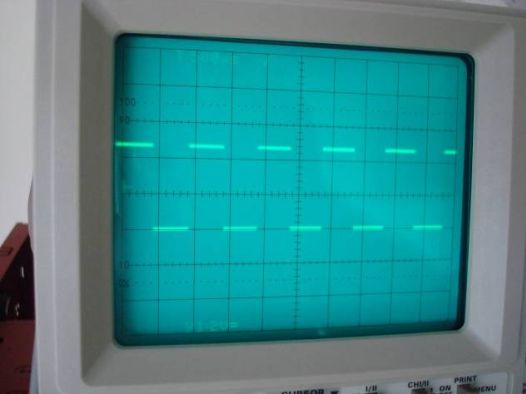

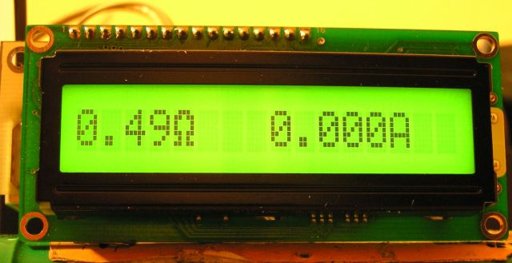

The function generator features two BNC outputs : one for the high speed [1 to 8 MHz] square signal (BNC1) and another for the DDS signal (BNC2). Offset and amplitude can be regulated by two potentiometers : offset in range of +5V to -5V (POT1) and amplitude in range of 0 to 10V (POT2). Up and down arrow buttons are used for changing the function type (sine, triangle etc.) while left and right arrow buttons are used for changing the frequency value. There is also a separate menu for changing frequency step. When the middle button is pressed, the signal generation starts. Middle button is pressed again for stopping the signal. More details can be found in the original site.

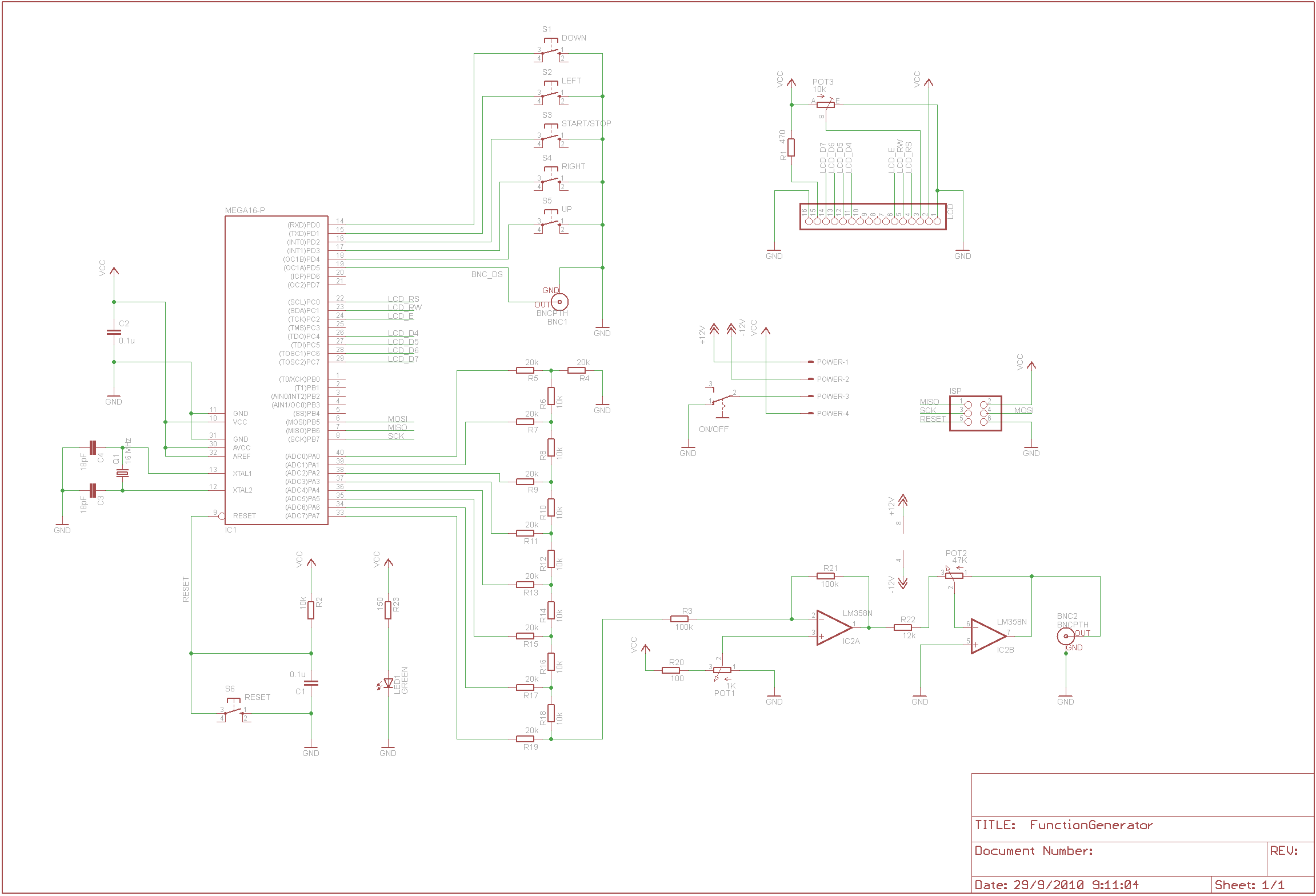

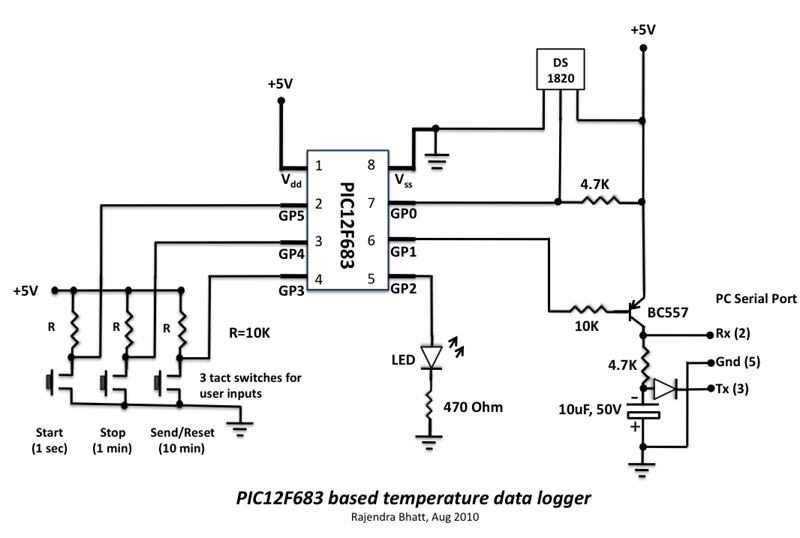

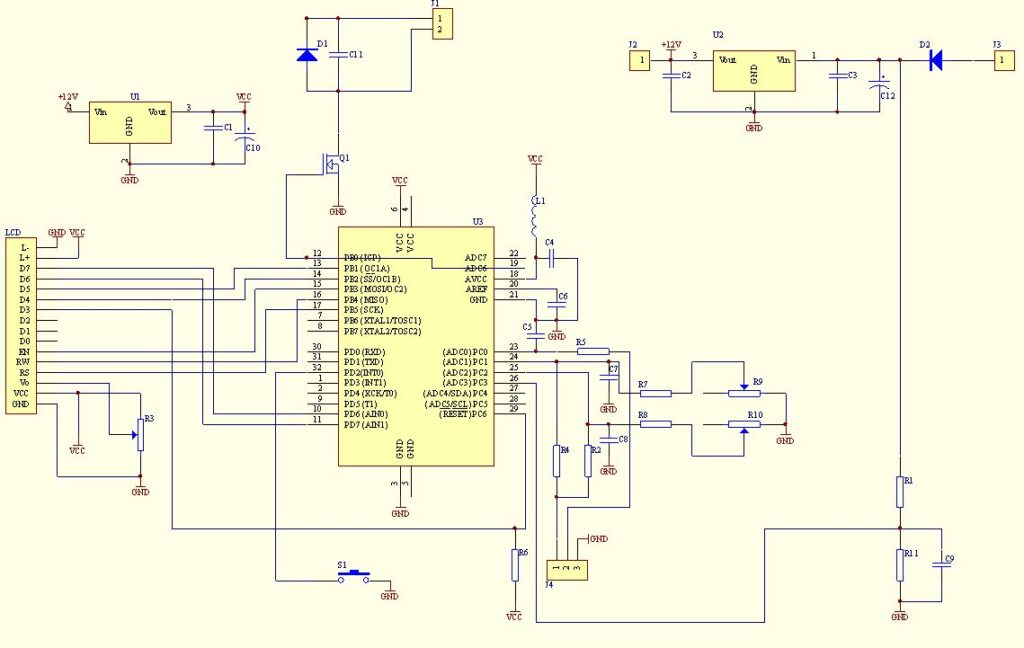

Schematic

EAGLE Schematic (only a status led and an on/off switch was added)

Parts

| Part | Value |

| R1 | 470 Ω ½W 5% |

| R2 | 10 ΚΩ ¼W 5% |

| R3 | 100 ΚΩ ¼W 1% |

| R4 | 20 ΚΩ ¼W 1% |

| R5 | 20 ΚΩ ¼W 1% |

| R6 | 10 ΚΩ ¼W 1% |

| R7 | 20 ΚΩ ¼W 1% |

| R8 | 10 ΚΩ ¼W 1% |

| R9 | 20 ΚΩ ¼W 1% |

| R10 | 10 ΚΩ ¼W 1% |

| R11 | 20 ΚΩ ¼W 1% |

| R12 | 10 ΚΩ ¼W 1% |

| R13 | 20 ΚΩ ¼W 1% |

| R14 | 10 ΚΩ ¼W 1% |

| R15 | 20 ΚΩ ¼W 1% |

| R16 | 10 ΚΩ ¼W 1% |

| R17 | 20 ΚΩ ¼W 1% |

| R18 | 10 ΚΩ ¼W 1% |

| R19 | 20 ΚΩ ¼W 1% |

| R20 | 100 Ω ¼W 5% |

| R21 | 100 ΚΩ ¼W 1% |

| R22 | 12 ΚΩ ¼W 1% |

| R23 | 150 Ω ¼W 5% |

| POT1 | 1 ΚΩ linear potentiometer |

| POT2 | 47 KΩ linear potentiometer |

| POT3 | 10 ΚΩ trimmer |

| C1 | 100 nF MKT/polyester |

| C2 | 100 nF MKT/polyester |

| C3 | 18 pF ceramic |

| C4 | 18 pF ceramic |

| Q1 | 16 MHz crystal |

| IC1 | ATMEL ATMEGA16P |

| IC2 | LM358N |

| BNC1 – BNC2 | BNC female connector |

| S1 – S6 | Push button |

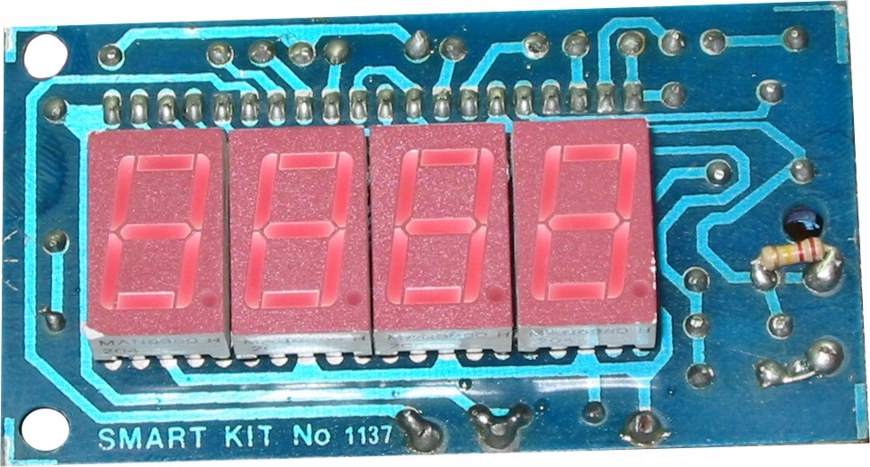

| LCD Header | Female header 16 pin for LCD |

| LCD Module | HD44780-based 2×16 character LCD |

| ISP | Male header 2×3 for ISP |

| POWER | Female header 4-pin for power as follows : PIN1 : +12V PIN2 : -12V PIN3 : GND PIN4 : +5V |

| LED1 | 3 mm green led |

| ON/OFF | Miniature on/off switch |

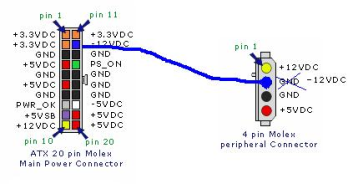

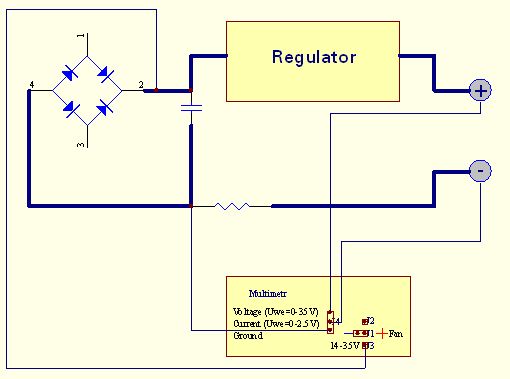

Power Supply

For powering up the function generator, a PC ATX power supply unit was used, where all voltages are already available (+12V, -12V, +5V). The wiring is shown in the following image, taken from scienceprog.com

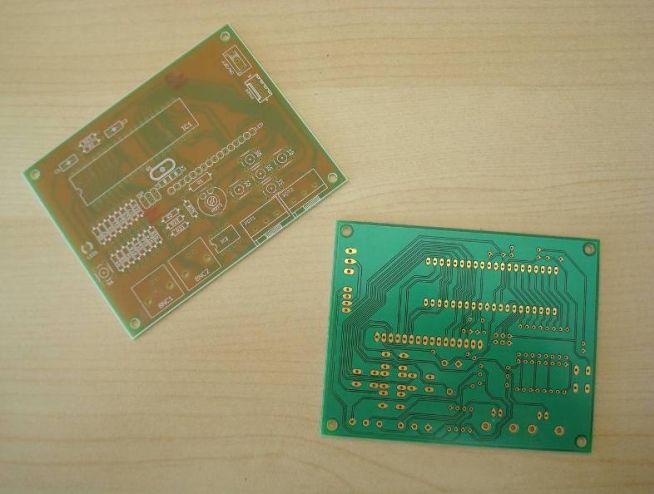

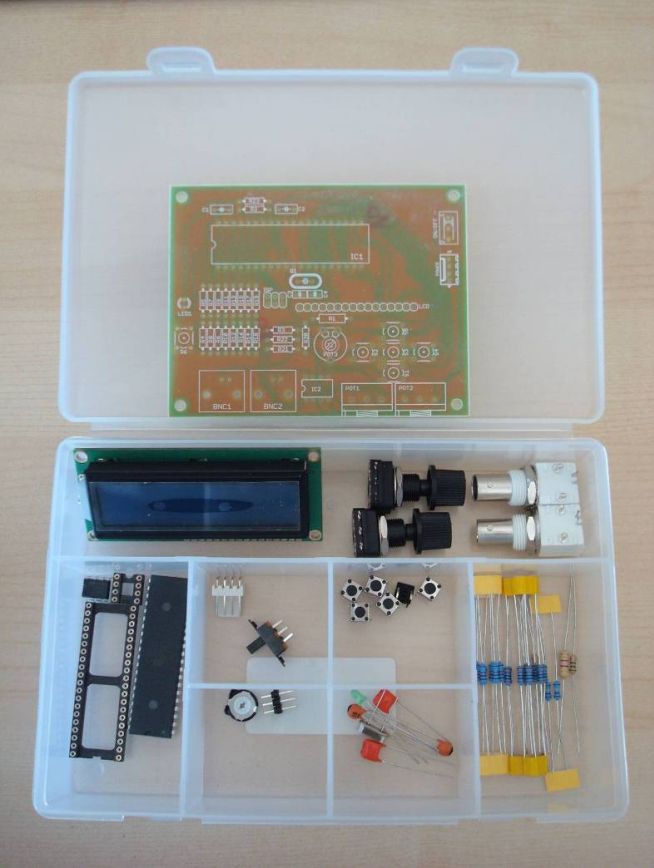

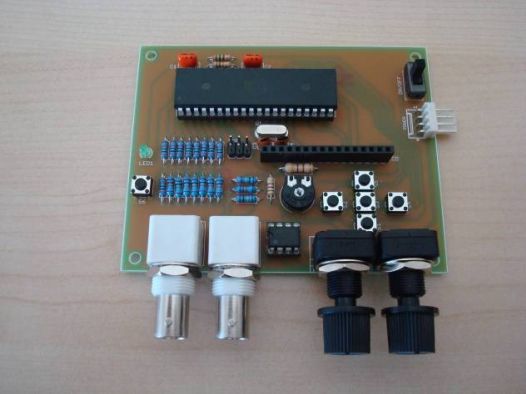

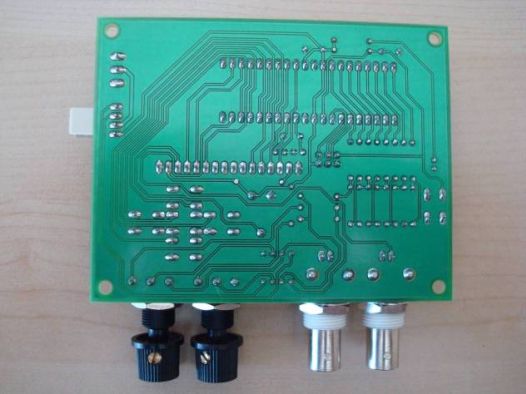

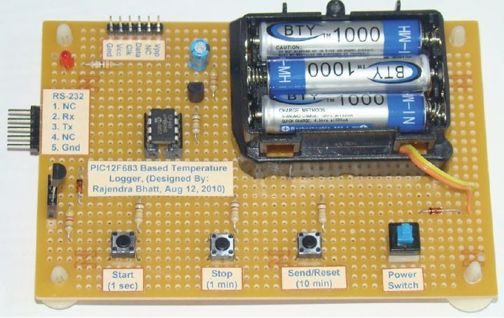

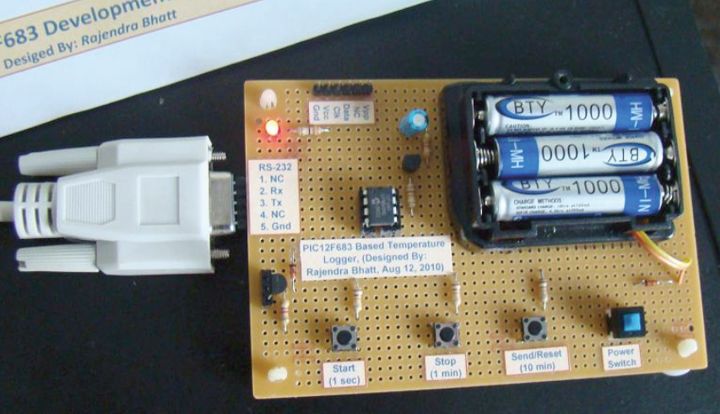

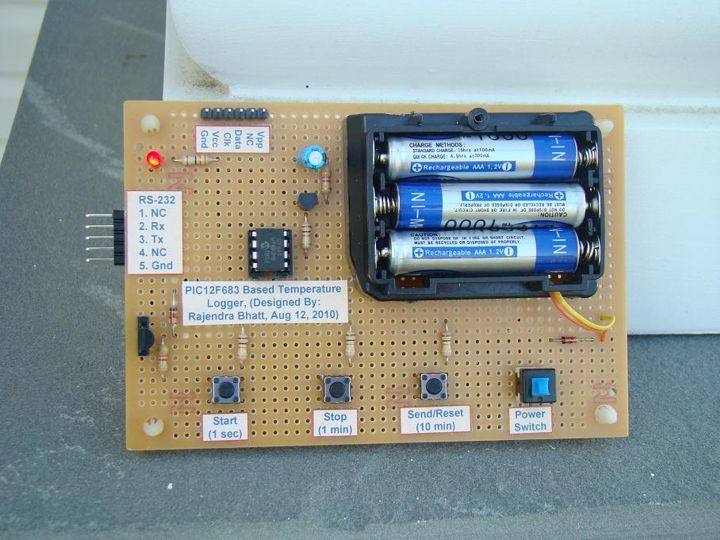

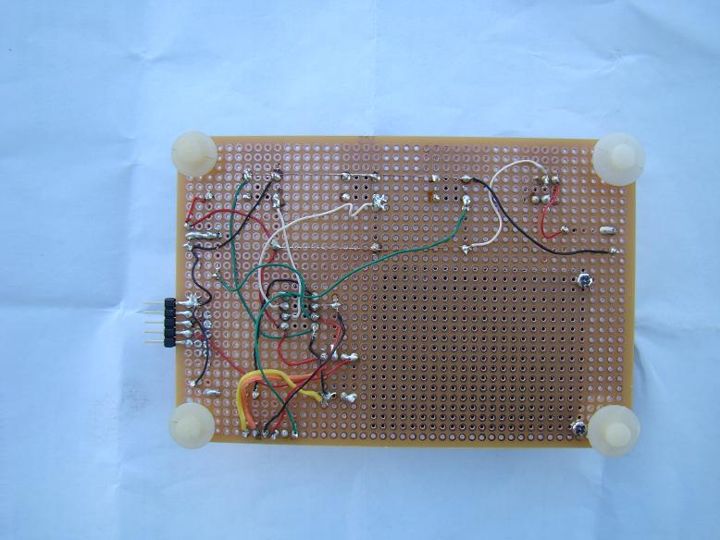

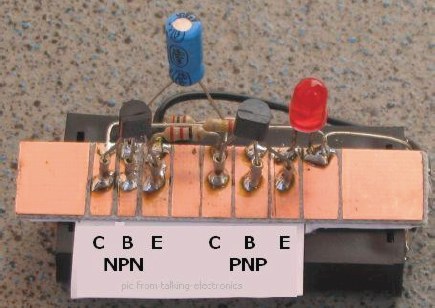

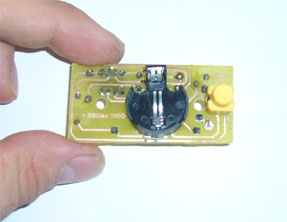

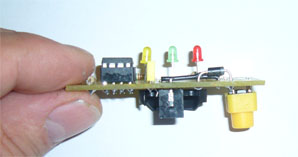

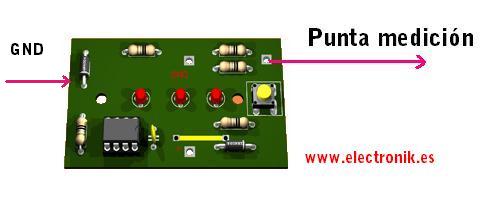

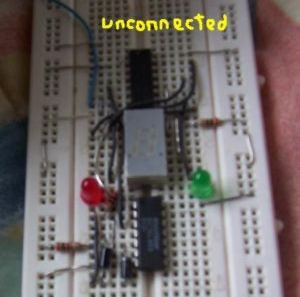

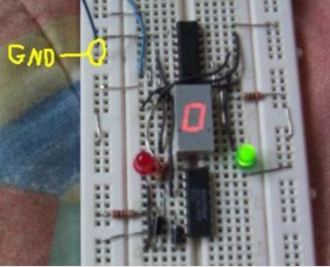

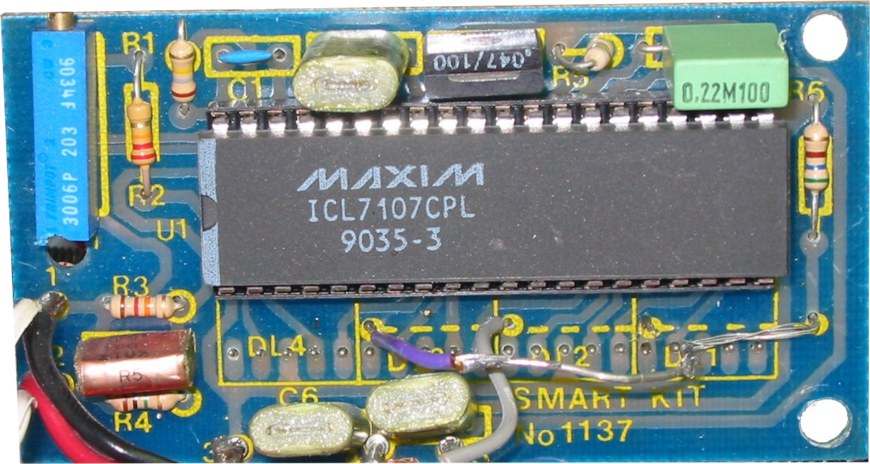

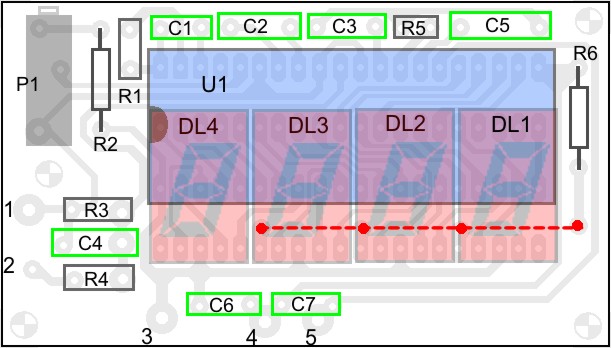

Photos of factory-made PCB and parts

Video

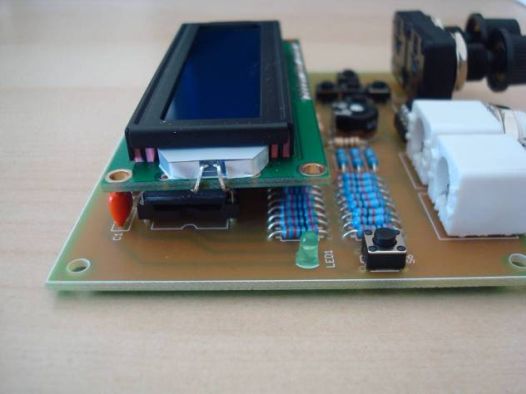

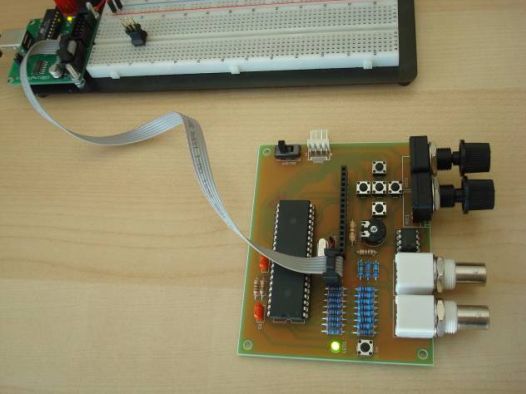

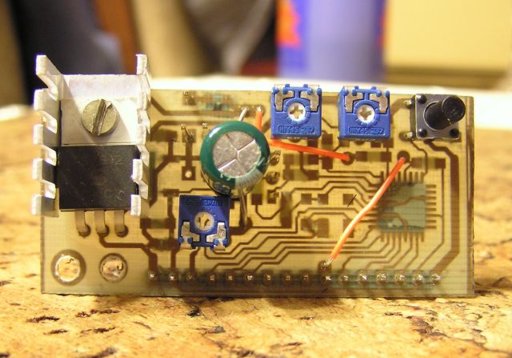

Photos of assembled PCB

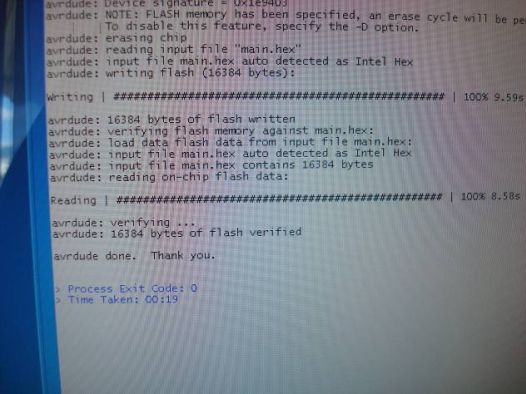

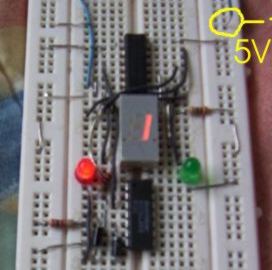

Programming of the ATMEGA16 with usbtiny programmer

The device firmware can be downloaded from :

http://www.scienceprog.com/avr-dds-signal-generator-v20

Changes in firmware

Because of the present LCD character orientation, which is different from the original implementation (180 degrees), the following changes in main.c were made : Buttons LEFT and RIGHT were reversed :

#define LEFT 3//PORTD #define RIGHT 1//PORTD

Buttons TOP and BOTTOM were reversed :

#define DOWN 4//PORTD #define UP 0//PORTD

For the latest version of AVR-GCC compiler, the following changes should be made (according to Geoff comment on scienceprog.com) :

struct signal{

volatile uint8_t mode; //signal

volatile uint8_t fr1; //Frequency [0..7]

volatile uint8_t fr2; //Frequency [8..15]

volatile uint8_t fr3; //Frequency [16..31]

volatile uint32_t freq; //frequency value

volatile uint8_t flag; //if 0 generator is OFF, 1 is ON

volatile uint32_t acc; //accumulator

volatile uint8_t ON;

volatile uint8_t HSfreq; //high speed frequency [1...4Mhz]

volatile uint32_t deltafreq; //frequency step value

}SG;

The ATMEGA16 fuses should be :

HIGH = 0×59 LOW = 0xCF

This is interpreted to the following options checked (all others unchecked) :

OCDEN SPIEN BOOTSZ1 BOOTSZ2 SUT1 SUT0