Copyright of this circuit belongs to smart kit electronics. In this page we will use this circuit to discuss for improvements and we will introduce some changes based on original schematic.

General Description

This is a small but quite powerful FM transmitter having three RF stages incorporating an audio preamplifier for better modulation. t has an output power of 4 Watts and works off 12-18 VDC which makes it easily portable. It is the ideal project for the beginner who wishes to get started in the fascinating world of FM broadcasting and wants a good basic circuit to experiment with.

Technical Specifications – Characteristics

- Modulation type: FM

- Frequency range: 88-108 MHz

- Working voltage: 12-18 VDC

- Maximum current: 450 mA

- Output power: 4 W

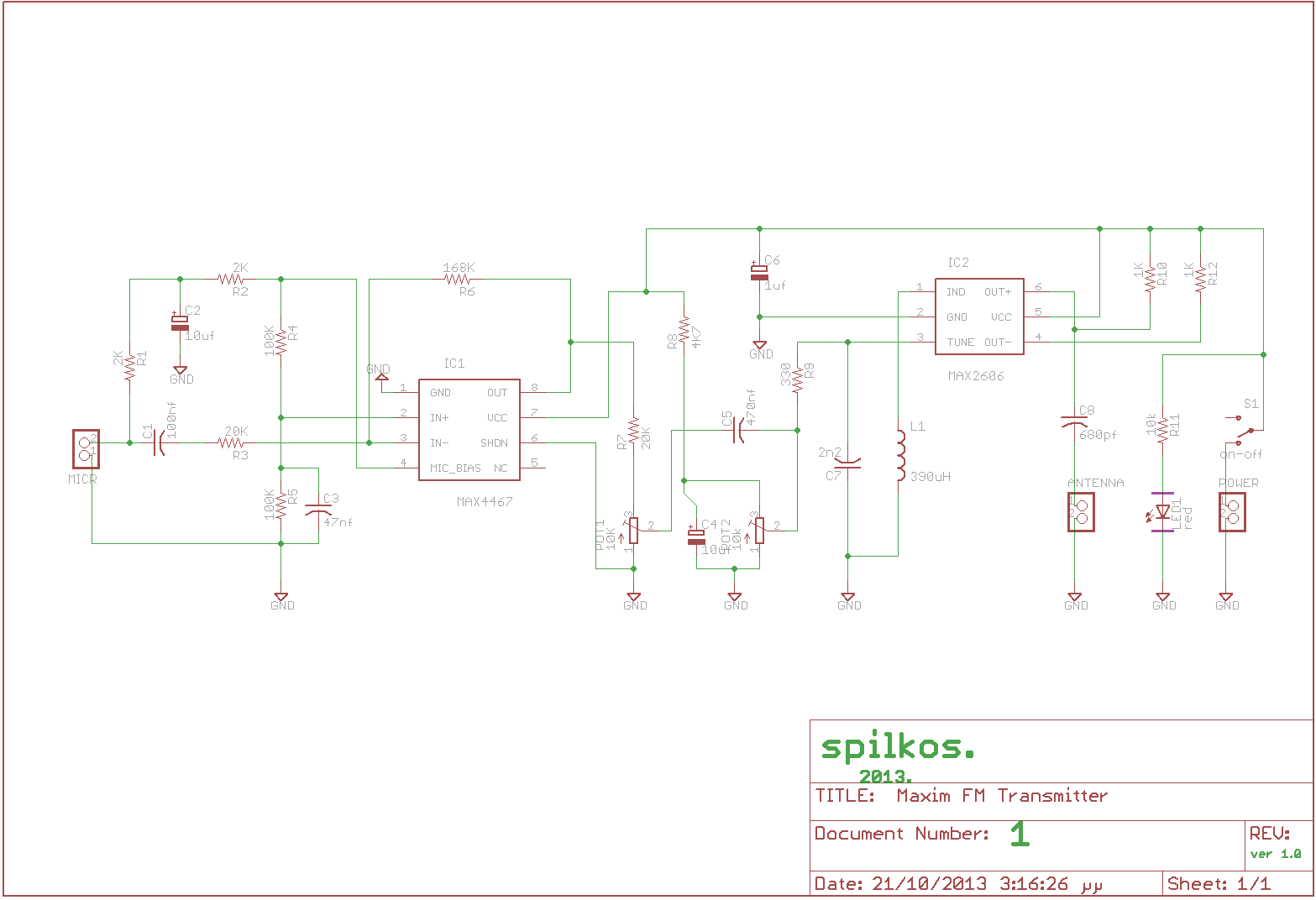

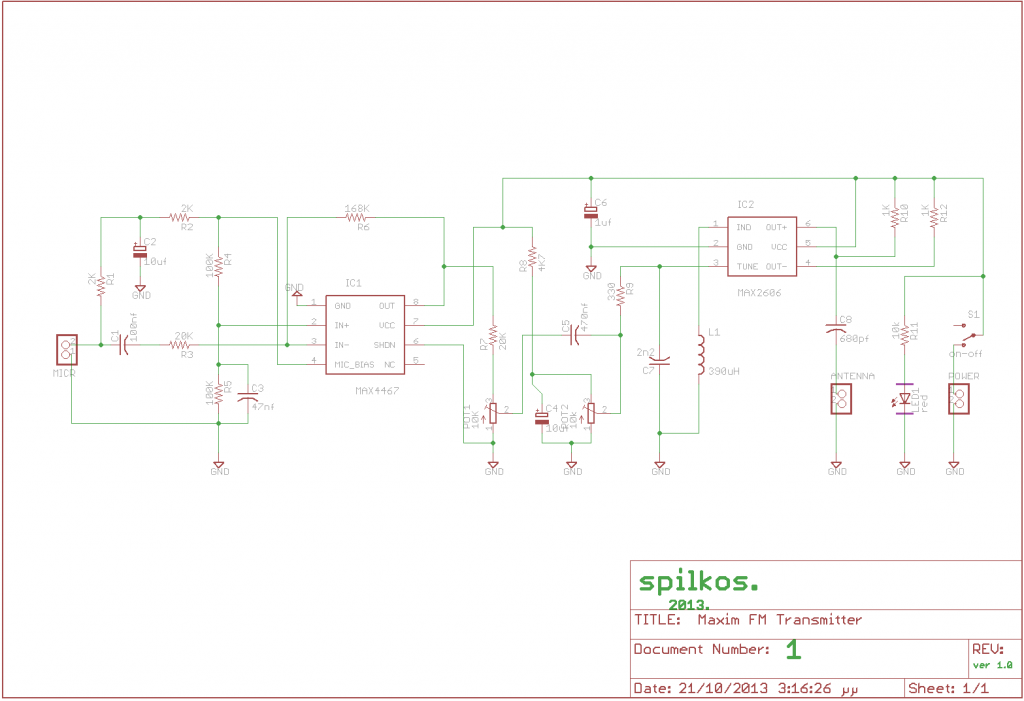

How it Works

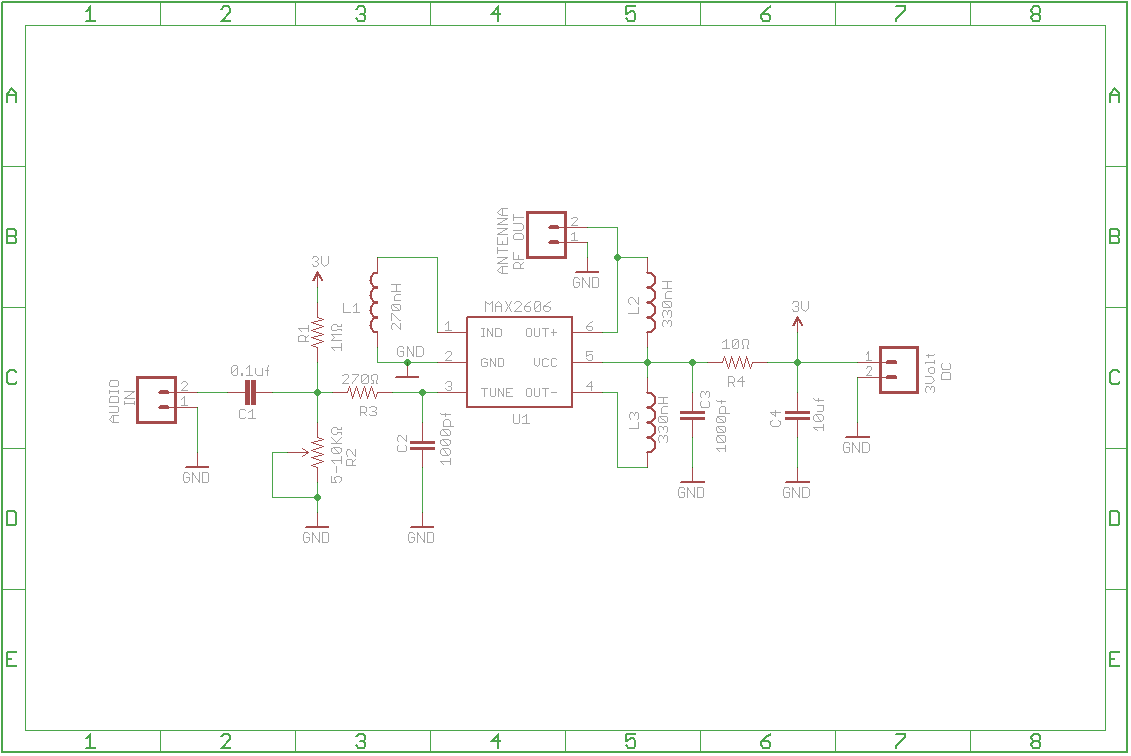

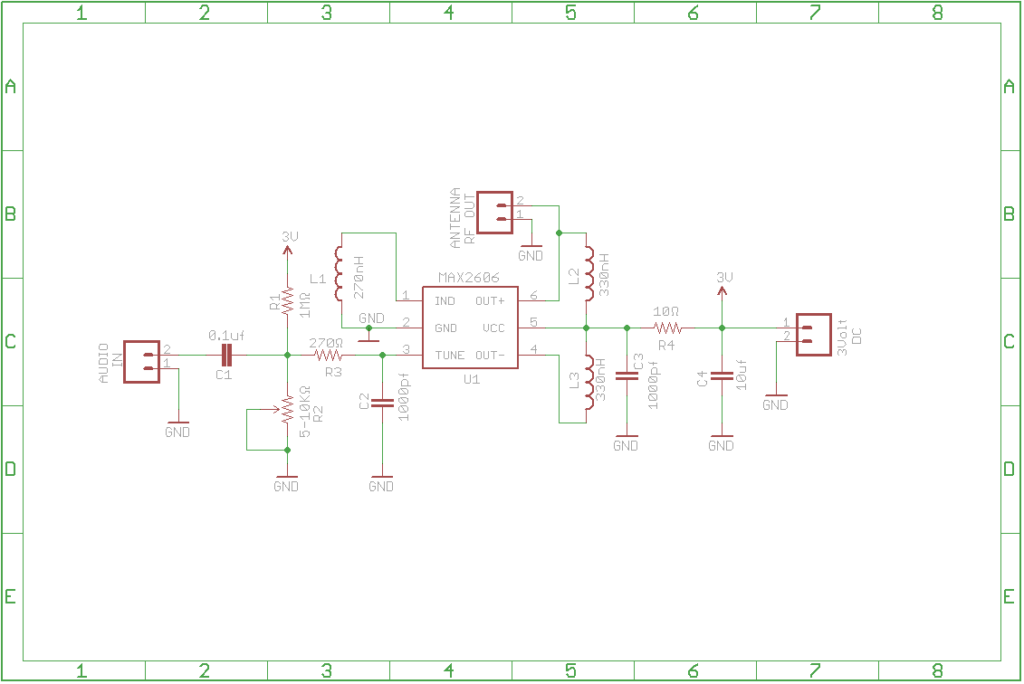

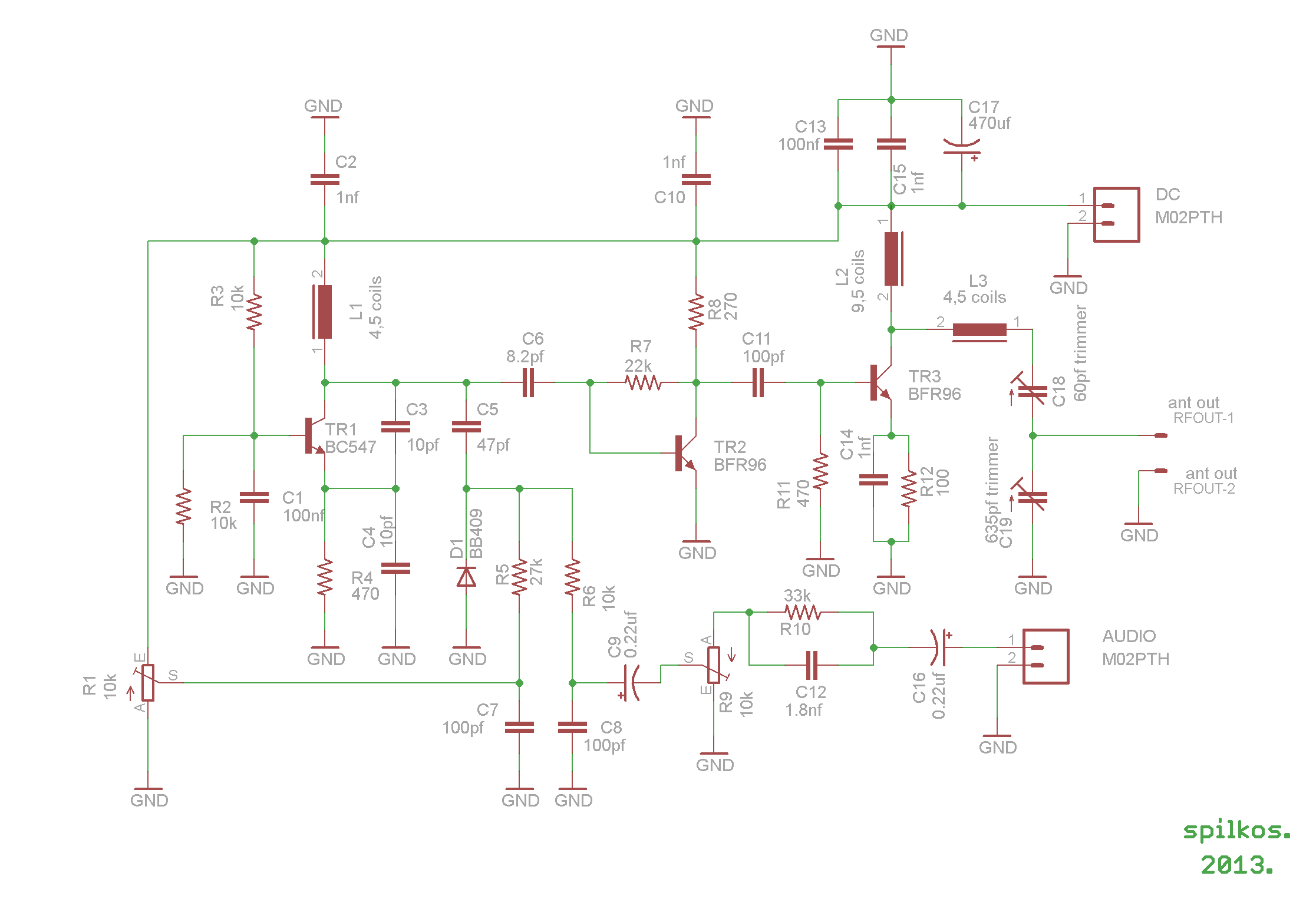

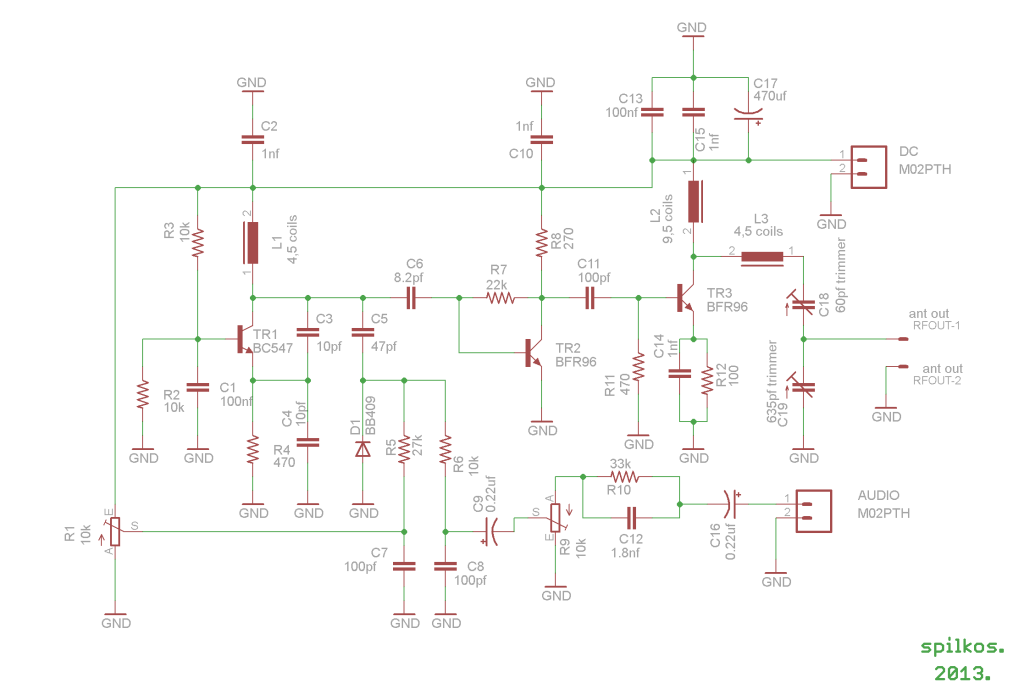

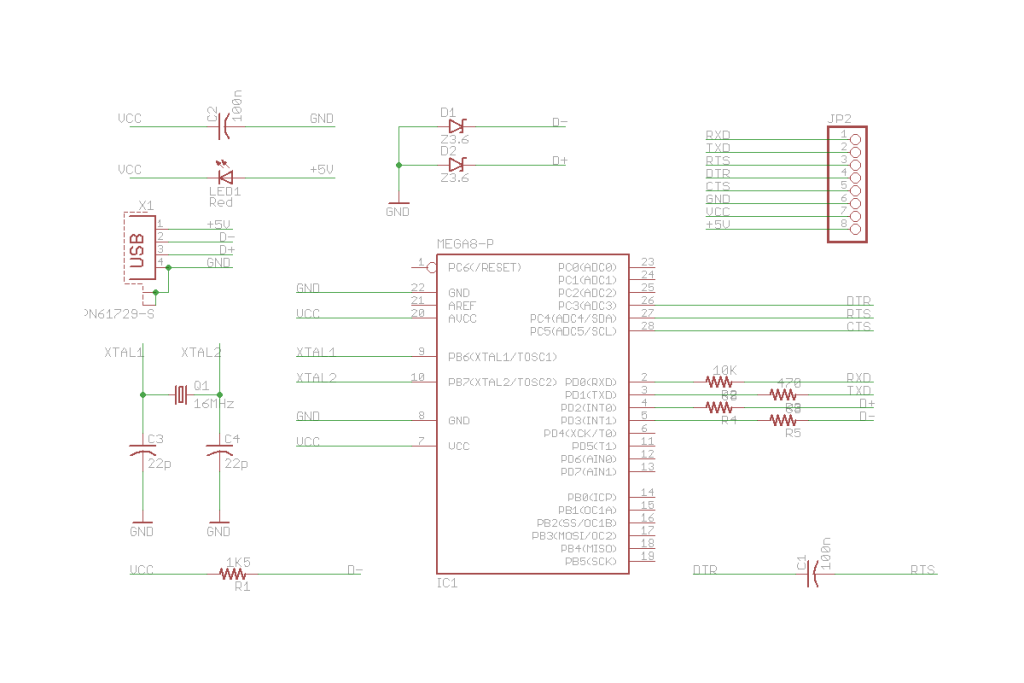

As it has already been mentioned the transmitted signal is Frequency Modulated (FM) which means that the carriers amplitude stays constant and its frequency varies according to the amplitude variations of the audio signal. When the input signals amplitude increases (i.e. during the positive half cycles) the frequency of the carrier increases too, on the other hand when the input signal decreases in amplitude (negative half-cycle or no signal) the carrier frequency decreases accordingly. In figure 1 you can see a graphic representation of Frequency Modulation as it would appear on an oscilloscope screen, together with the modulating AF signal. The output frequency the transmitter is adjustable from 88 to 108 MHz which is the FM band that is used for radio broadcasting. The circuit as we have already mentioned consists of four stages. Three RF stages and one audio preamplifier for the modulation. The first RF stage is an oscillator and is built around TR1. The frequency of the oscillator is controlled by the LC network L1-C15. C7 is there to ensure that the circuit continues oscillating and C8 adjusts the coupling between the oscillator and the next RF stage which is an amplifier. This is built around TR2 which operates in class C and is tuned by means of L2 and C9. The last RF stage is also an amplifier built around TR3 which operates in class C the input of which is tuned by means of C10 and L4. From the output of this last stage which is tuned by means of L3-C12 is taken the output signal which through the tuned circuit L5-C11 goes to the aerial.

The circuit of the preamplifier is very simple and is built around TR4. The input sensitivity of the stage is adjustable in order to make it possible to use the transmitter with different input signals and depends upon the setting of VR1. As it is the transmitter can be modulated directly with a piezoelectric microphone, a small cassette recorder etc. It is of course possible to use an audio mixer in the input for more professional results.

Construction

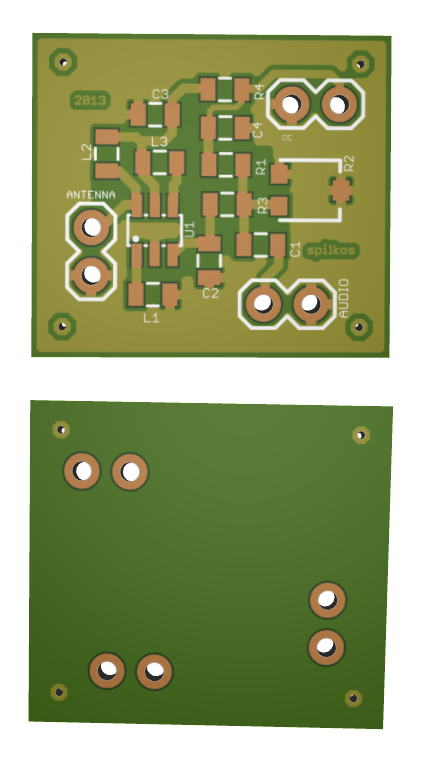

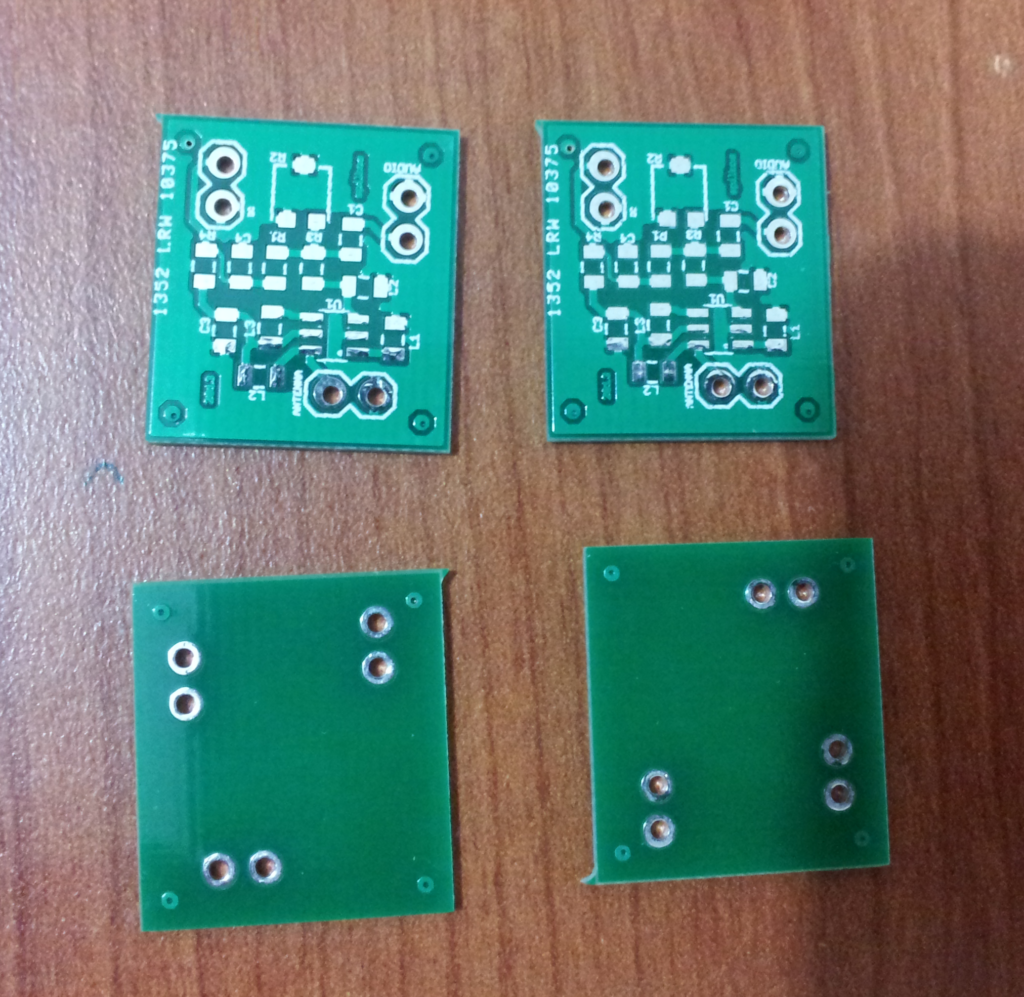

First of all let us consider a few basics in building electronic circuits on a printed circuit board. The board is made of a thin insulating material clad with a thin layer of conductive copper that is shaped in such a way as to form the necessary conductors between the various components of the circuit. The use of a properly designed printed circuit board is very desirable as it speeds construction up considerably and reduces the possibility of making errors. Smart Kit boards also come pre-drilled and with the outline of the components and their identification printed on the component side to make construction easier. To protect the board during storage from oxidation and assure it gets to you in perfect condition the copper is tinned during manufacturing and covered with a special varnish that protects it from getting oxidised and also makes soldering easier. Soldering the components to the board is the only way to build your circuit and from the way you do it depends greatly your success or failure. This work is not very difficult and if you stick to a few rules you should have no problems. The soldering iron that you use must be light and its power should not exceed the 25 Watts. The tip should be fine and must be kept clean at all times. For this purpose come very handy specially made sponges that are kept wet and from time to time you can wipe the hot tip on them to remove all the residues that tend to accumulate on it. DO NOT file or sandpaper a dirty or worn out tip. If the tip cannot be cleaned, replace it. There are many different types of solder in the market and you should choose a good quality one that contains the necessary flux in its core, to assure a perfect joint every time. DO NOT use soldering flux apart from that which is already included in your solder. Too much flux can cause many problems and is one of the main causes of circuit malfunction. If nevertheless, you have to use extra flux, as it is the case when you have to tin copper wires, clean it very thoroughly after you finish your work.

In order to solder a component correctly you should do the following:

- Clean the component leads with a small piece of emery paper.

- Bend them at the correct distance from the components body and insert the component in its place on the board.

- You may find sometimes a component with heavier gauge leads than usual, that is too thick to enter in the holes of the p.c. board. In this case, use a mini drill to enlarge the holes slightly.

- Do not make the holes too large as this is going to make soldering difficult afterward.

- Take the hot iron and place its tip on the component lead while holding the end of the solder wire at the point where the lead emerges from the board. The iron tip must touch the lead slightly above the p.c. board. – When the solder starts to melt and flow wait till it covers evenly the area around the hole and the flux boils and gets out from underneath the solder. The whole operation should not take more than 5 seconds. Remove the iron and allow the solder to cool naturally without blowing on it or moving the component. If everything was done properly the surface of the joint must have a bright metallic finish and its edges should be smoothly ended on the component lead and the board track. If the solder looks dull, cracked, or has the shape of a blob then you have made a dry joint and you should remove the solder (with a pump, or a solder wick) and redo it.

- Take care not to overheat the tracks as it is very easy to lift them from the board and break them.

- When you are soldering a sensitive component it is good practice to hold the lead from the component side of the board with a pair of long-nose pliers to divert any heat that could possibly damage the component.

- Make sure that you do not use more solder than it is necessary as you are running the risk of short-circuiting adjacent tracks on the board, especially if they are very close together.

- When you finish your work cut off the excess of the component leads and

clean the board thoroughly with a suitable solvent to remove all flux residues that may still remain on it.

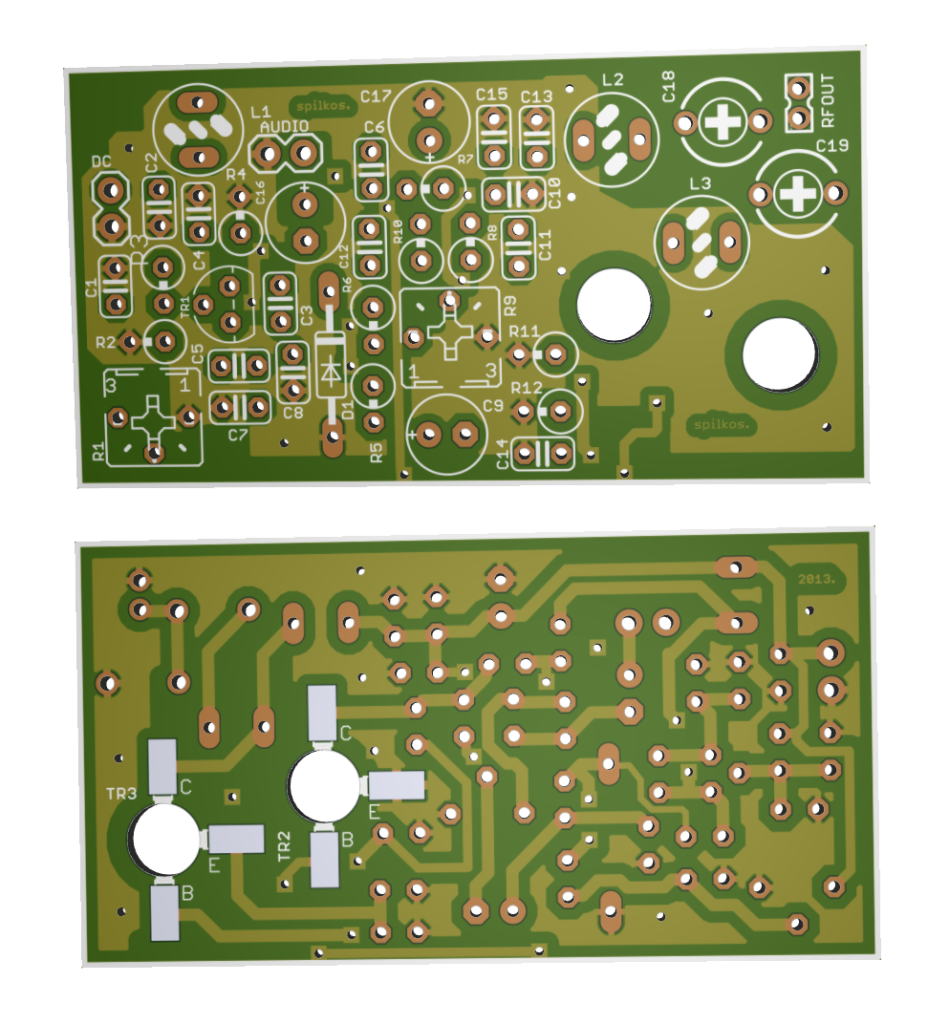

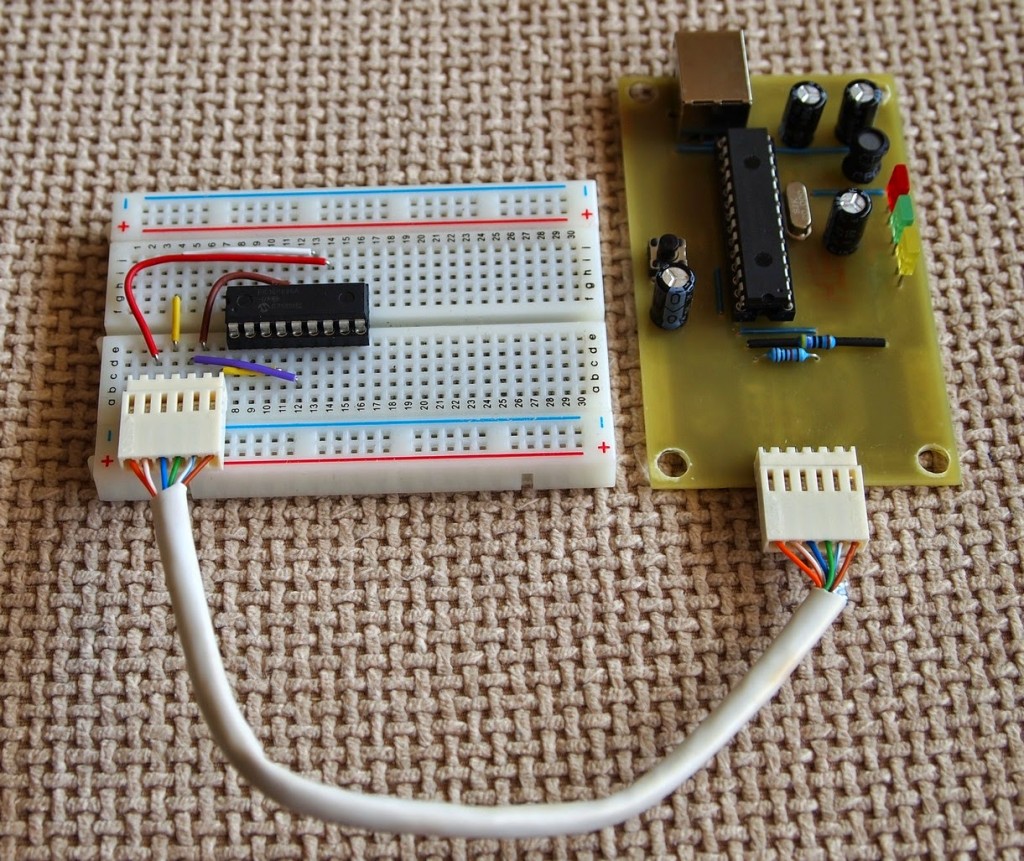

This is an RF project and this calls for even more care during soldering as sloppiness during construction can mean low or no output at all, low stability and other problems. Make sure that you follow the general rules about electronic circuit construction outlined above and double-check everything before going to the next step. All the components are clearly marked on the component side of the P.C. board and you should have no difficulty in locating and placing them. Solder first of all the pins, and continue with the coils taking care not to deform them, the RFCs, the resistors, the capacitors and finally the electrolytic and the trimmers. Make sure that the electrolytic are correctly placed with respect to their polarity and that the trimmers are not overheated during soldering. At this point stop for a good inspection of the work done so far and if you see that everything is OK go on and solder the transistors in their places taking grate care not to overheat them as they are the most sensitive of all the components used in the project. The audio frequency input is at points 1 (ground) and 2 (signal), the power supply is connected at points 3 (-) and 4 (+) and the antenna is connected at points 5 (ground) and 6 (signal). As we have already mentioned the signal you use for the modulation of the transmitter could be the output of a preamplifier or mixer or in case you only want to modulate it with voice you can use the piezoelectric microphone supplied with the Kit. (The quality of this microphone is not very good but it is quite adequate if you are interested in speech only.) As an antenna you can use an open dipole or a Ground Plane. Before you start using the transmitter or every time you change its working frequency you must follow the procedure described below which is called alignment.

Parts List

R1 = 220K

R2 = 4,7K

R3 = R4 = 10K

R5 = 82 Ohm

R = 150Ohm 1/2W x2 *

VR1 = 22K trimmer

C1 = C2 = 4,7uF 25V electrolytic

C3 = C13 = 4,7nF ceramic

C4 = C14 = 1nF ceramic

C5 = C6 = 470pF ceramic

C7 = 11pF ceramic

C8 = 3-10pF trimmer

C9 = C12 = 7-35pF trimmer

C10 = C11 = 10-60pF trimmer

C15 = 4-20pF trimmer

C16 = 22nF ceramic *

L1 = 4 turns of silver coated wire at 5,5mm diameter

L2 = 6 turns of silver coated wire at 5,5mm diameter

L3 = 3 turns of silver coated wire at 5,5mm diameter

L4 = printed on PCB

L5 = 5 turns of silver coated wire at 7,5mm diameter

RFC1=RFC2=RFC3= VK200 RFC tsok

TR1 = TR2 = 2N2219 NPN

TR3 = 2N3553 NPN

TR4 = BC547/BC548 NPN

D1 = 1N4148 diode *

MIC = crystalic microphone

Note: Parts marked with * are used for the tune-up of the transmitter in case you have not a stationary wave bridge.

Adjustments

If you expect your transmitter to be able to deliver its maximum output at any time you must align all the RF stages in order to ensure that you get the best energy transfer between them. There are two ways to do this and it depends if you have a SWR meter or not which method you are going to follow. If you have a SWR meter turn the transmitter on, having connected the SWR meter in its output in series with the antenna, and turn C15 in order to tune the oscillator to the frequency you have chosen for your broad casts. Then start adjusting the trimmers C8,9,10,12 and 11 in this order till you get the maximum output power in the SWR meter. For those who dont have a SWR meter there is another method which gives quite satisfactory results. You only have to build the little circuit in Fig. 2 which is connected in the out put of the transmitter and in its output (across C16) you connect your multi-tester having selected a suitable VOLTS scale. You tune C15 in the desired frequency and then adjust the other trimmers in the same order as it is described above for the maximum output in the multitester. The disadvantage of this method is that you do not align the transmitter with a real antenna connected in its output and it may be necessary to make slight adjustments to C11 and C12 for a perfect antenna match.

Do not forget to align your transmitter every time you change your aerial or your working frequency.

WARNING: In every transmitter there are present apart from the main output frequency various harmonics that usually have a very short range. In order to make sure you havent tuned on one of them do the tuning as far as possible from your receiver, or use a Spectrum Analyser to see your output spectrum and make sure that you tune your transmitter on the right frequency.

Warning

Smart kits are sold as stand alone training kits.

If they are used as part of a larger assembly and any damage is caused, our company bears no responsibility.

While using electrical parts, handle power supply and equipment with great care, following safety standards as described by international specs and regulations.

CAUTION

All the RF kits are sold for experimental and laboratory use only. Their possession and use are limited by laws which vary from state to state. Please get information about what you can or can not do in your area and stay within the legal limits. Make sure you do not become a nuisance to others with your experiments. Smart Kit has no responsibility whatsoever for any misuse of its products.

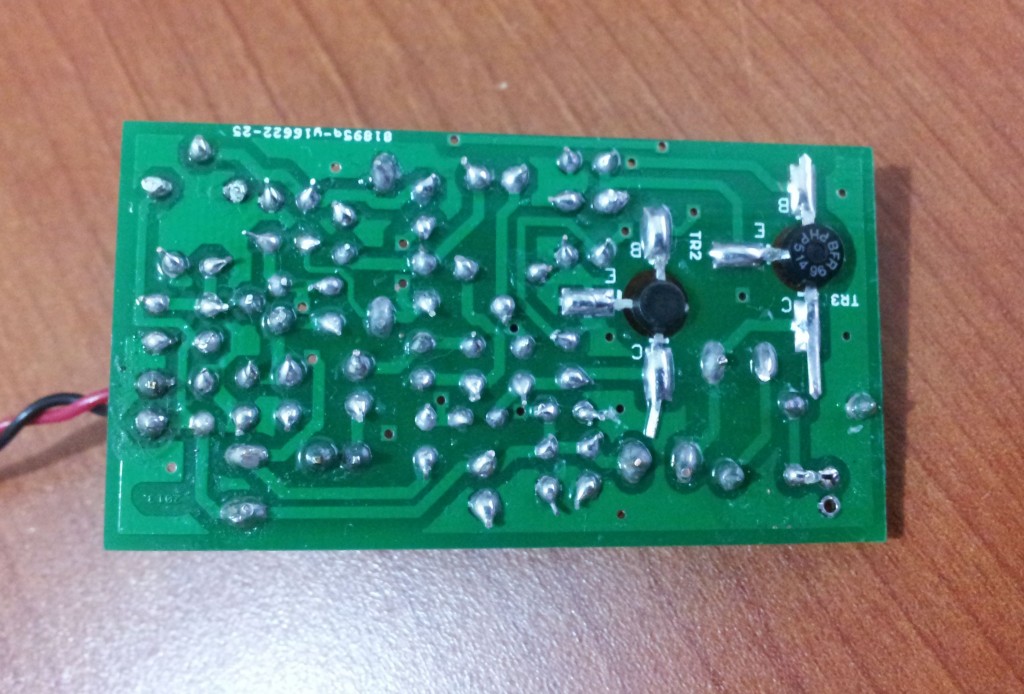

If it does not work

- Check your work for possible dry joints, bridges across adjacent tracks or soldering flux residues that usually cause problems.

- Check again all the external connections to and from the circuit to see if there is a mistake there.

- See that there are no components missing or inserted in the wrong places.

- Make sure that all the polarised components have been soldered the right way round.

- Make sure that the supply has the correct voltage and is connected the right way round to your circuit.

- Check your project for faulty or damaged components.

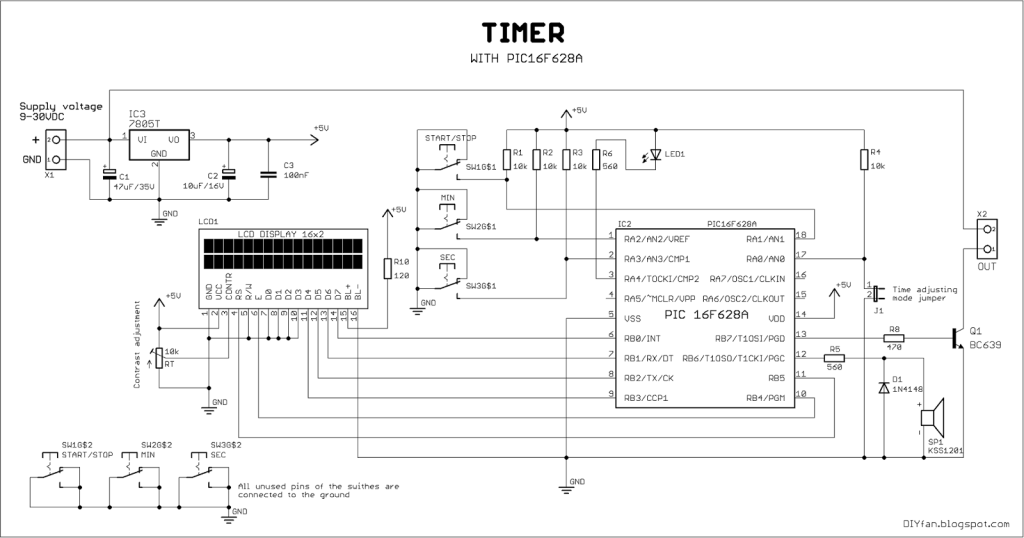

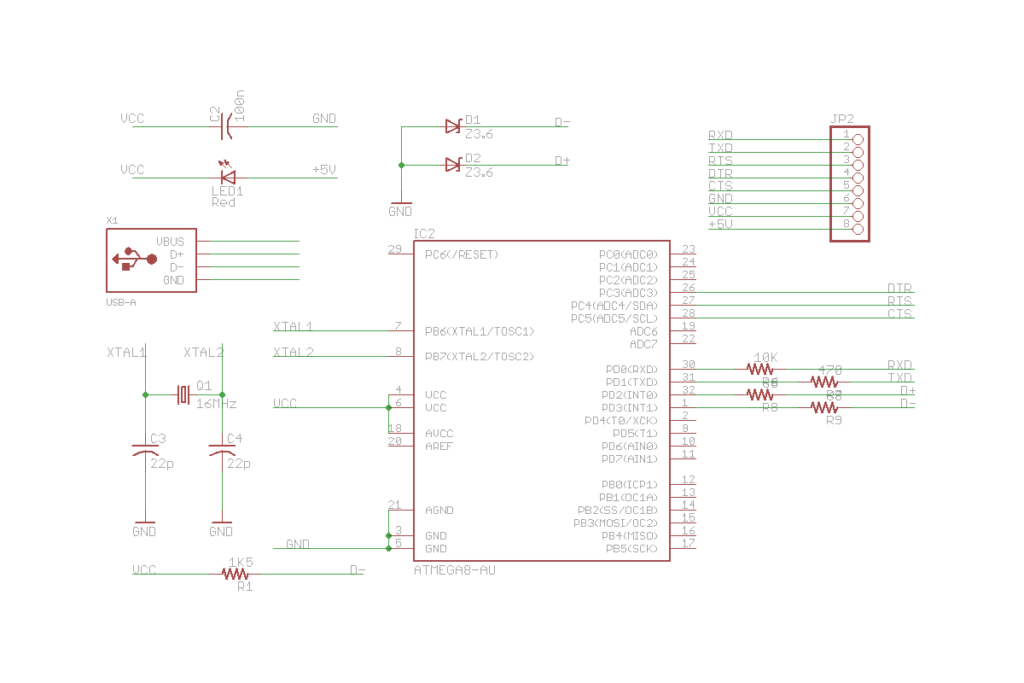

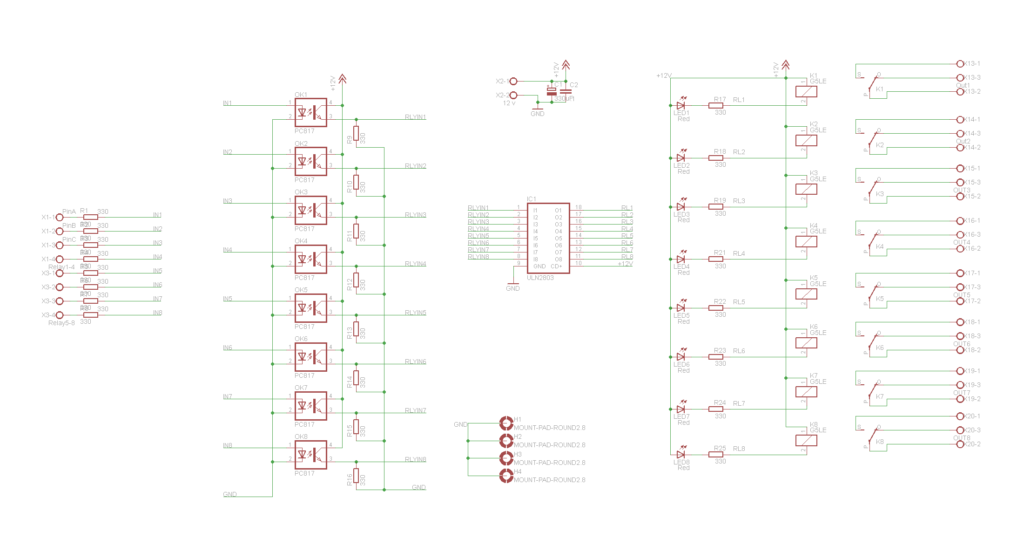

Electronic Diagram

Also check this site for additional information

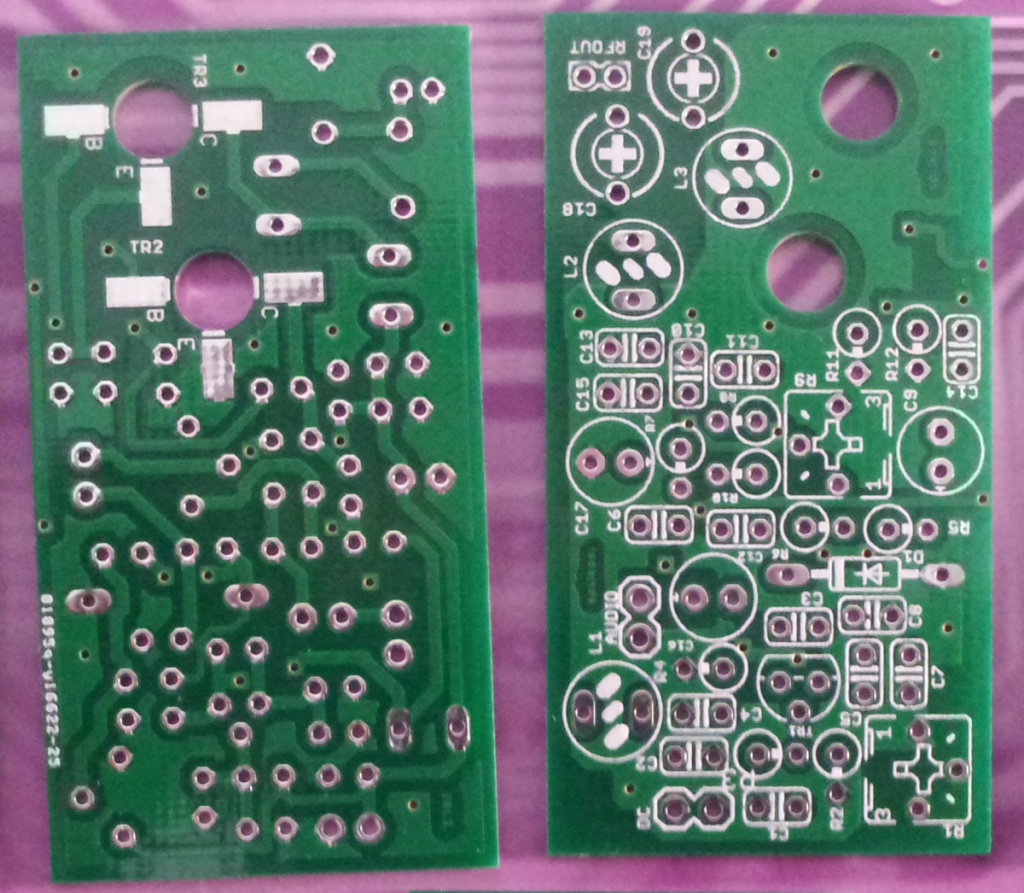

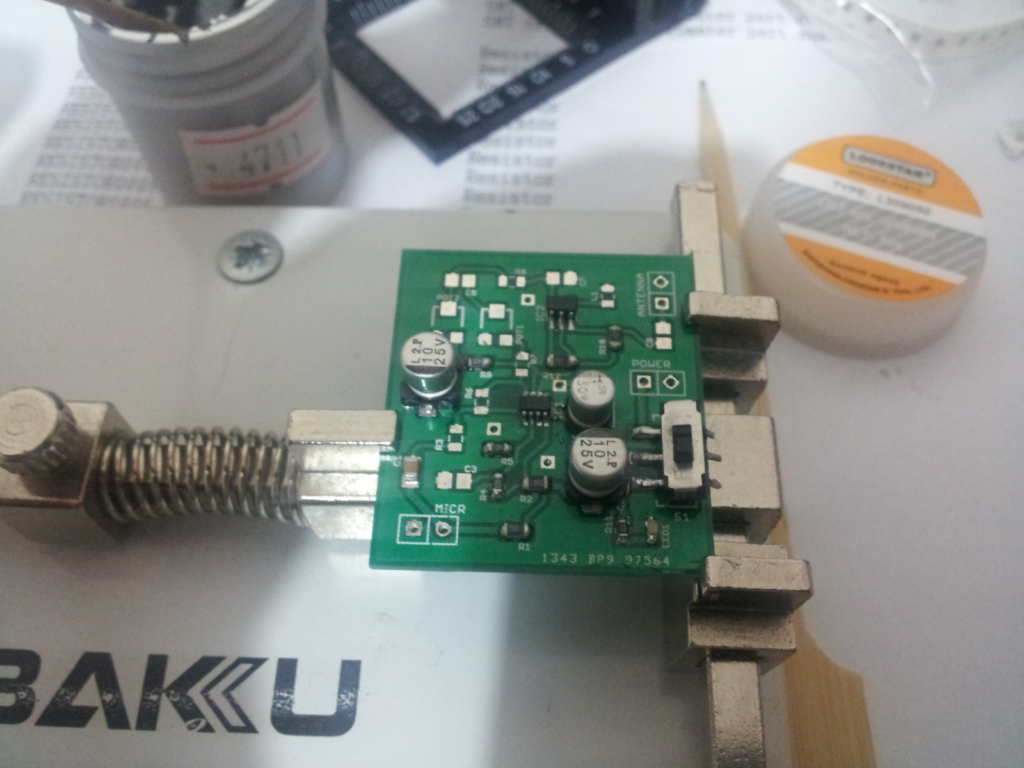

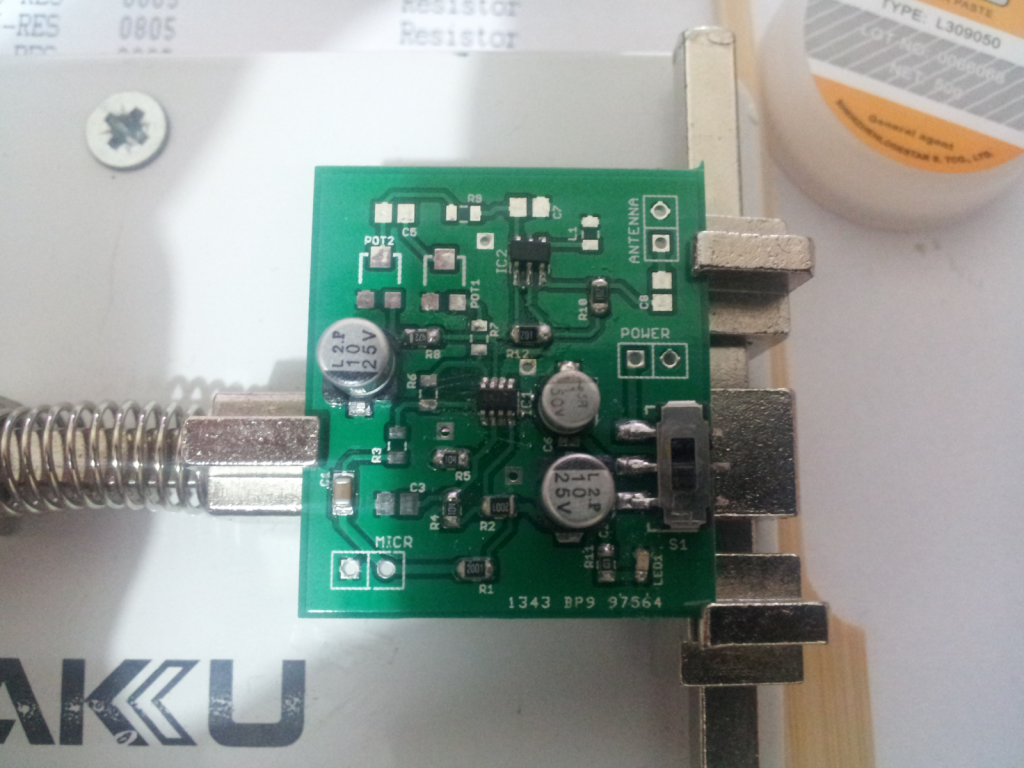

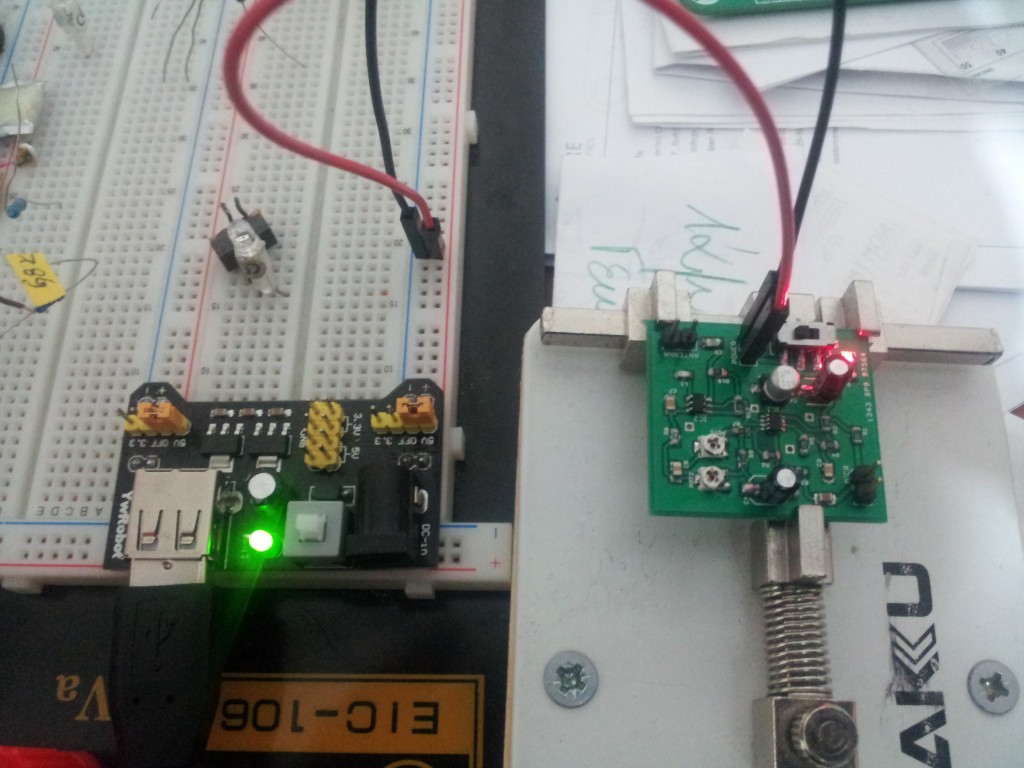

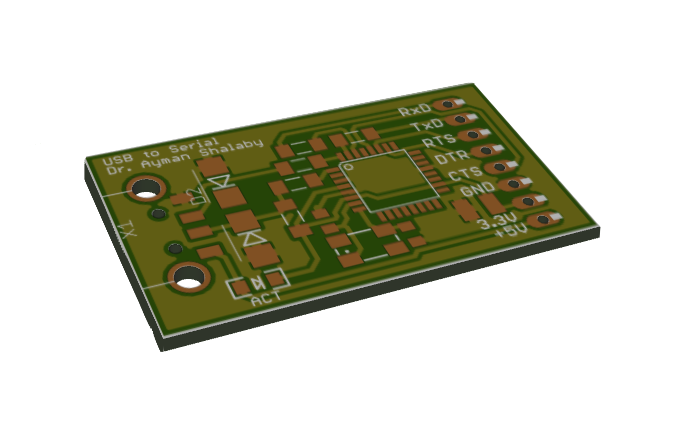

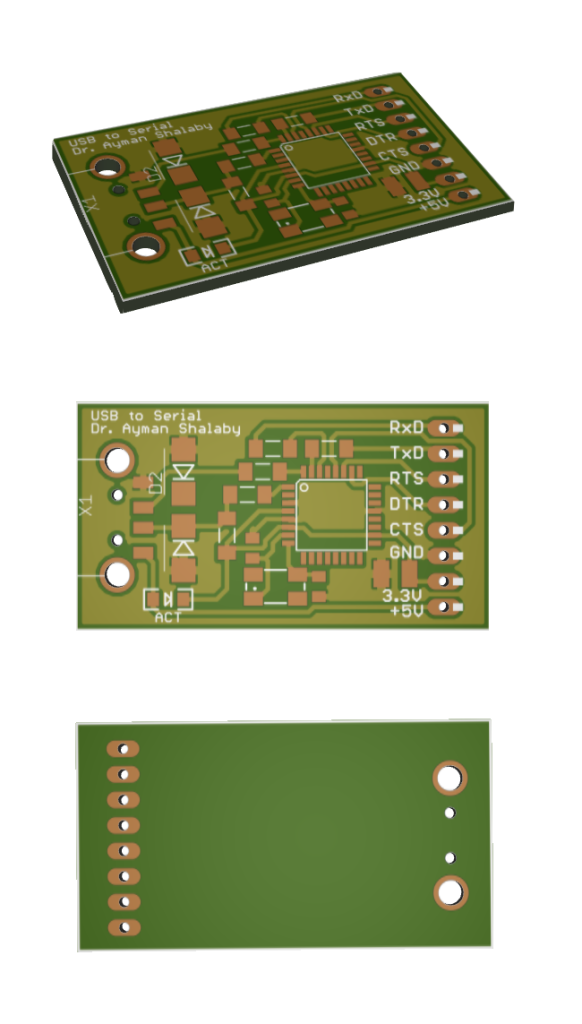

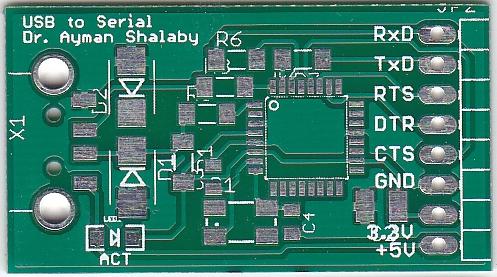

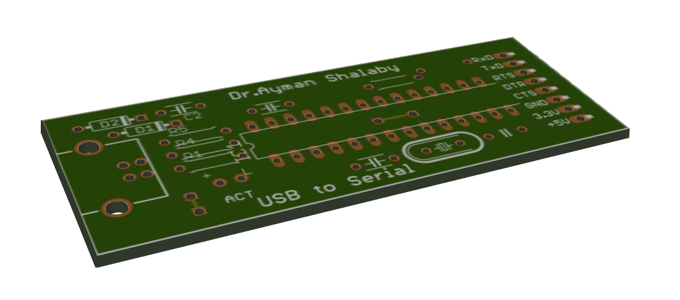

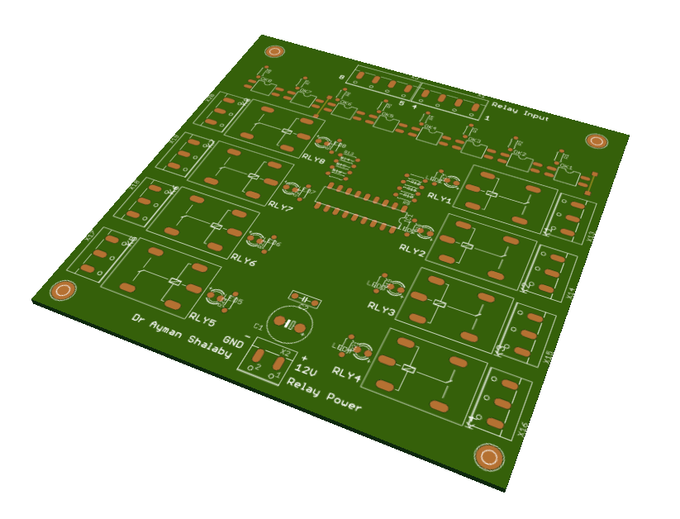

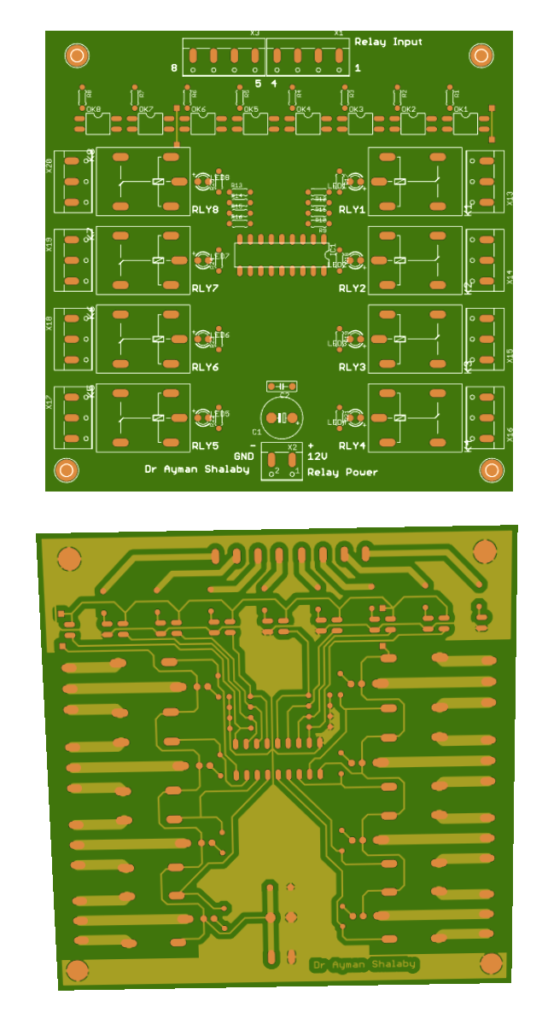

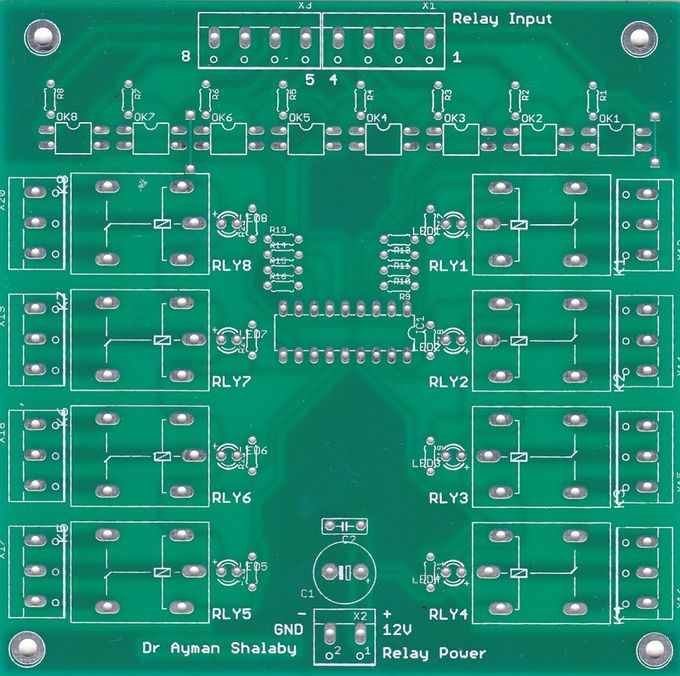

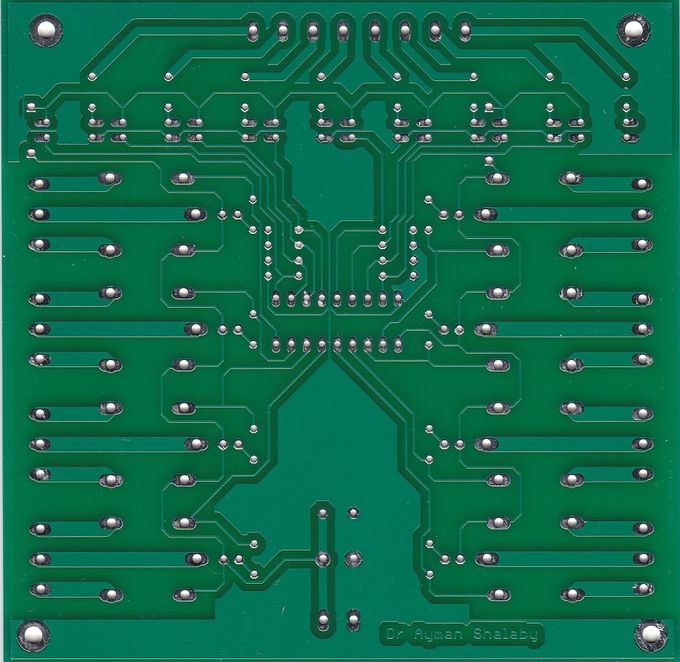

Improvements on original design

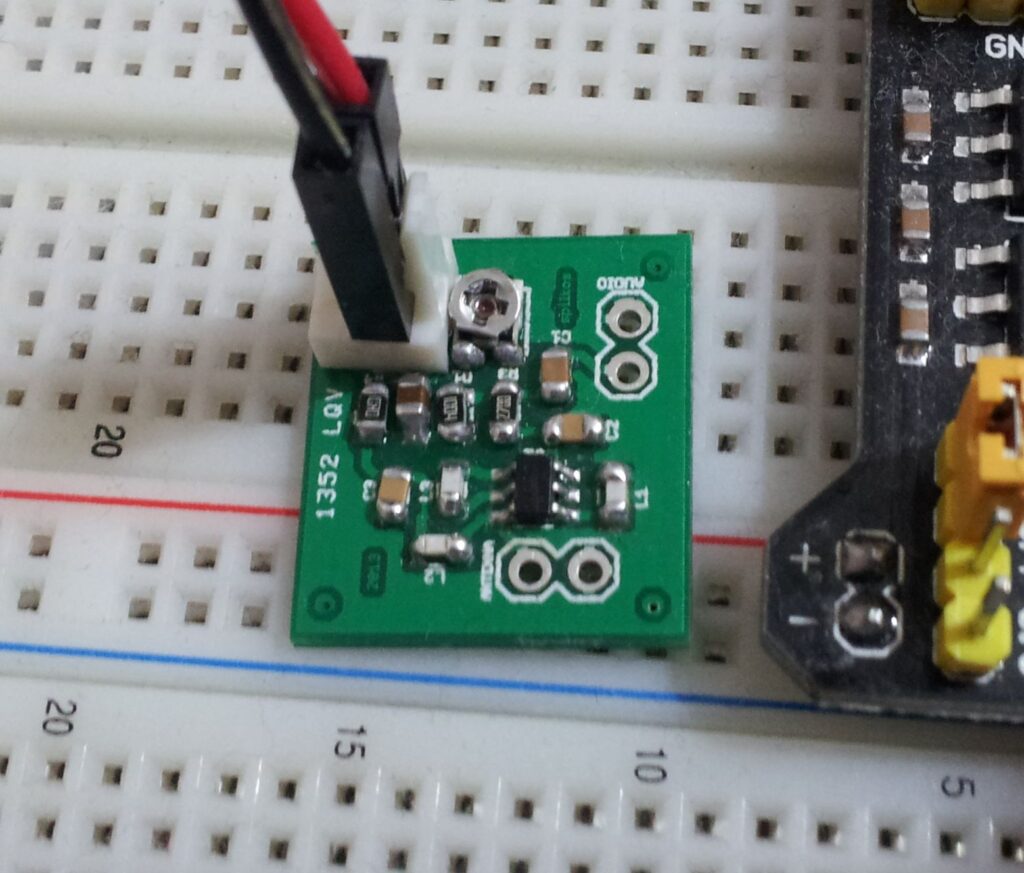

Thomas [thomasciciyan @ yahoo.com] made some improvement on original design:

- The ability for capacitor microphone

- Preamplifier for the mic

- External audio input jack, for example: to transmit sounds from a computer audio card

- A selector switch to select microphone or input jack

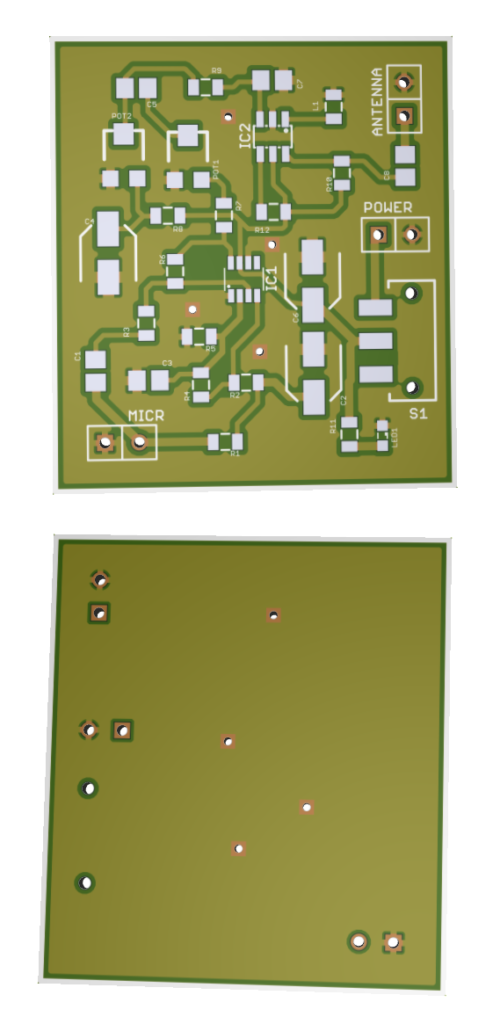

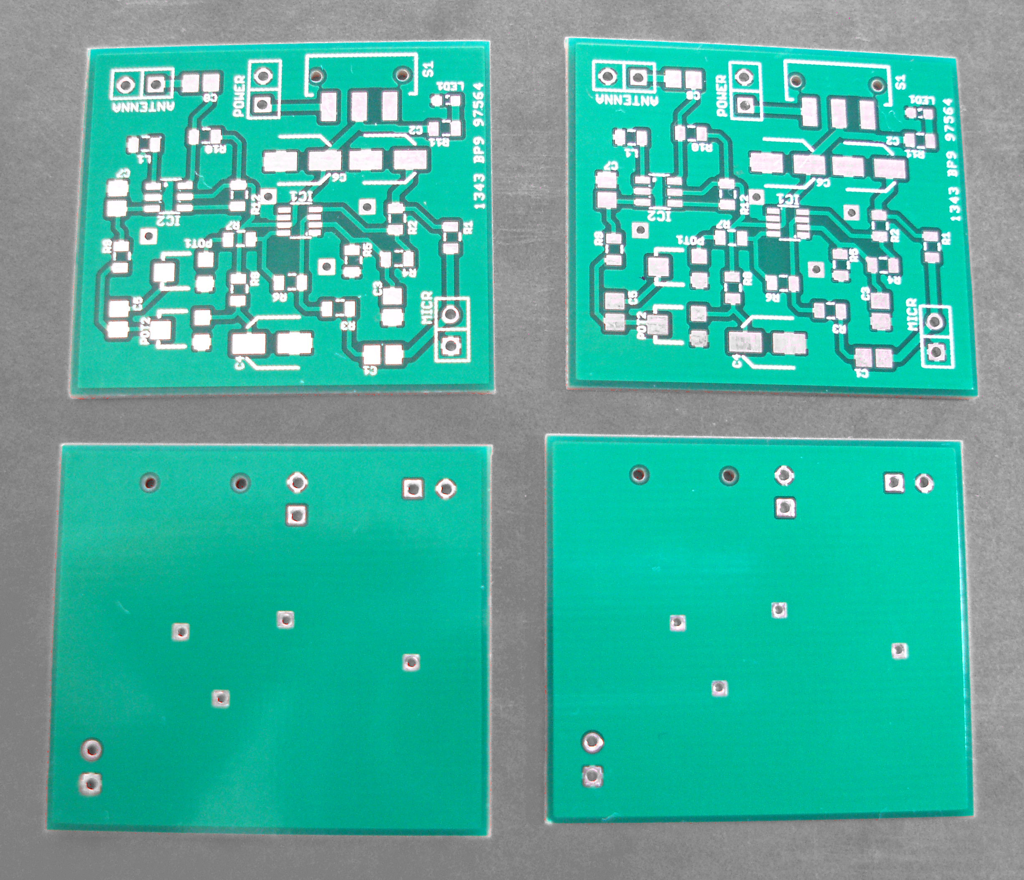

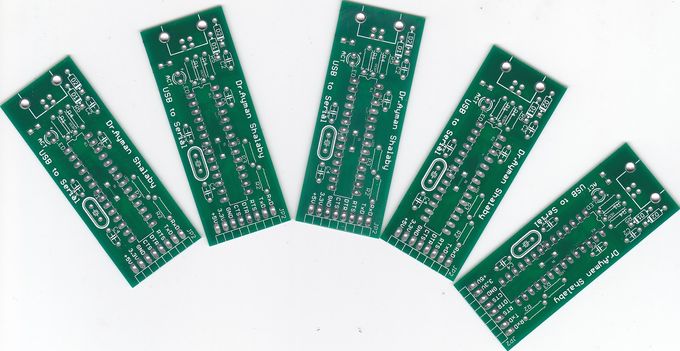

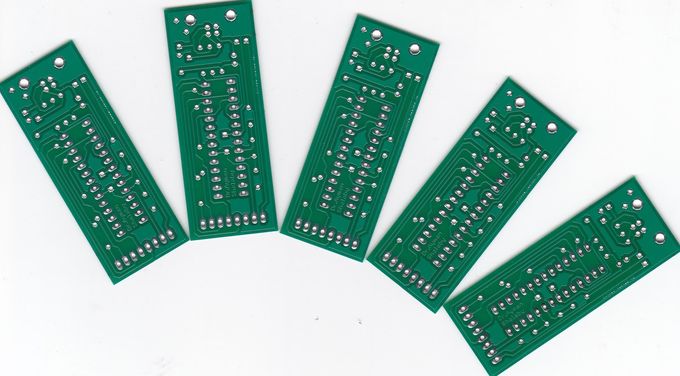

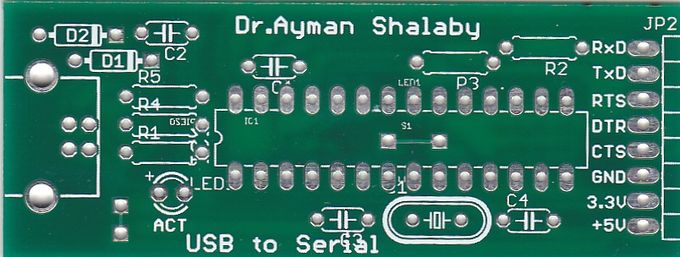

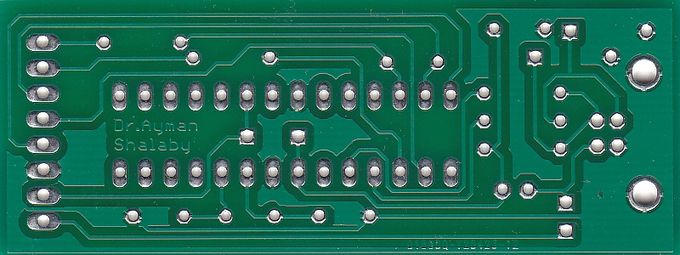

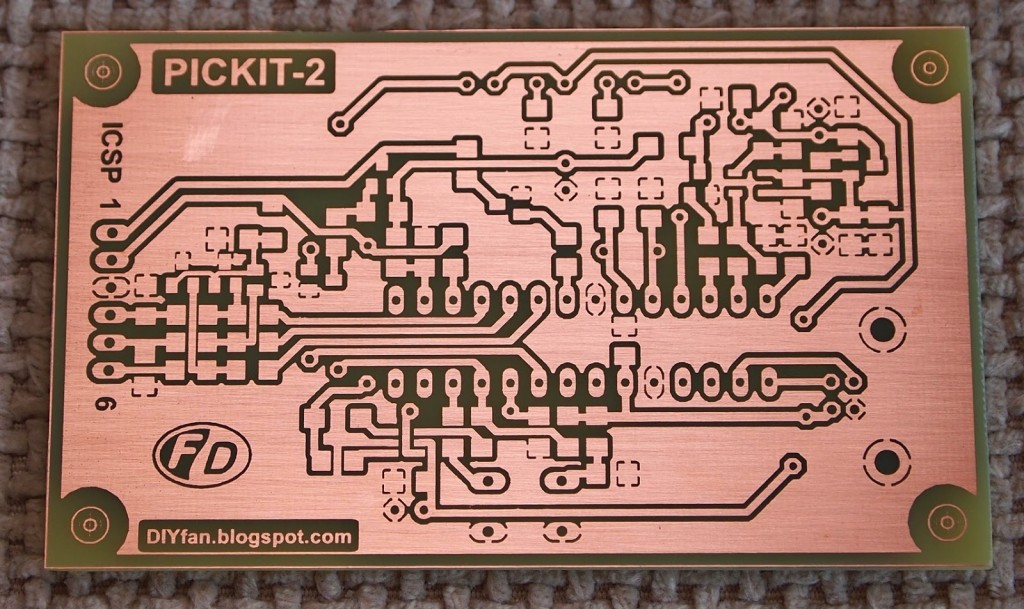

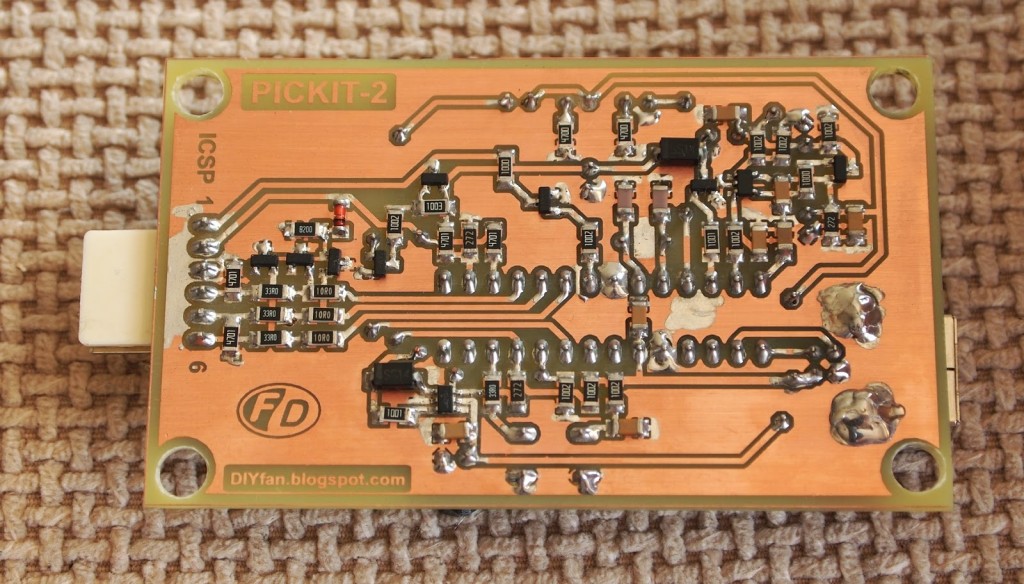

- PCB redesign

Parts added

C17 (1uf)

C18 (4uf7)

C19 (4uf7)

C20 (100NF)

H1 (13*13*10MM)

JACK1 (STEREO)

LED2 (RED)

MIC (CAPACITIC)

R6 (1M8)

R7 (1K5)

R8 (560K)

R9 (820R)

R10 (4K7)

R11 (4K7)

R12 (1K)

R13 (1K)

R14 (2K2)

R15 (680R)

TR5 (BC547\BC548)

VR1 (50K)