This project started out from a need to build a simple device for monitoring the CAN bus. I choose the NUC140LC1CN 32K Cortex-M0 microprocessor from Nuvoton for major reason – it has both USB and CAN peripherals.

Features

- Simple design

- Compatible with the LAWICEL CANUSB protocol

- Exposing itself as USB FTDI device

- Supporting CAN 2.0A 11-bit and CAN 2.0B 29-bit frames

- Has internal FIFO CAN message buffer

- Self powered from USB port

- Flash-resident USB mass-storage device (MSD) bootloader for firmware updates

- Firmware is available for download on the link below

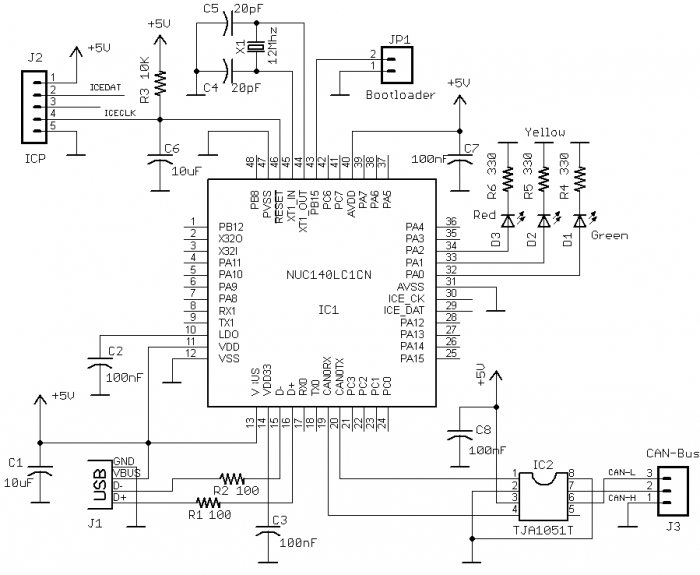

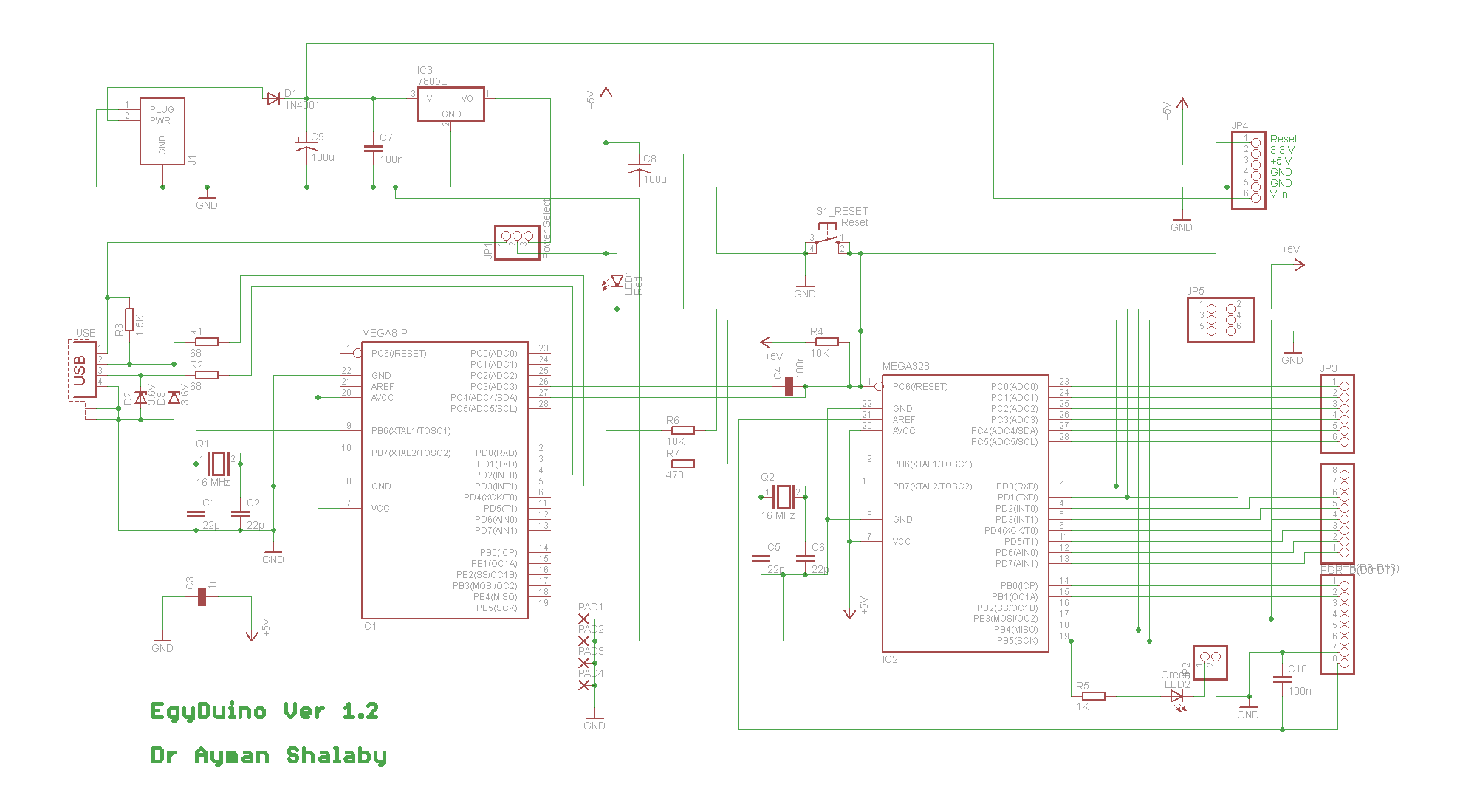

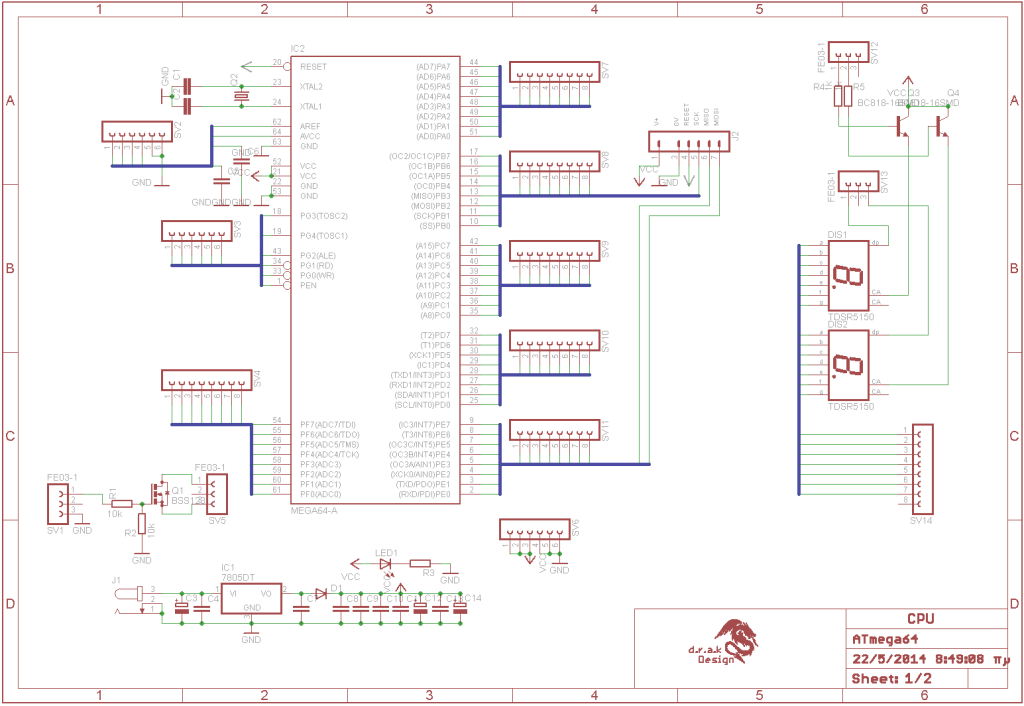

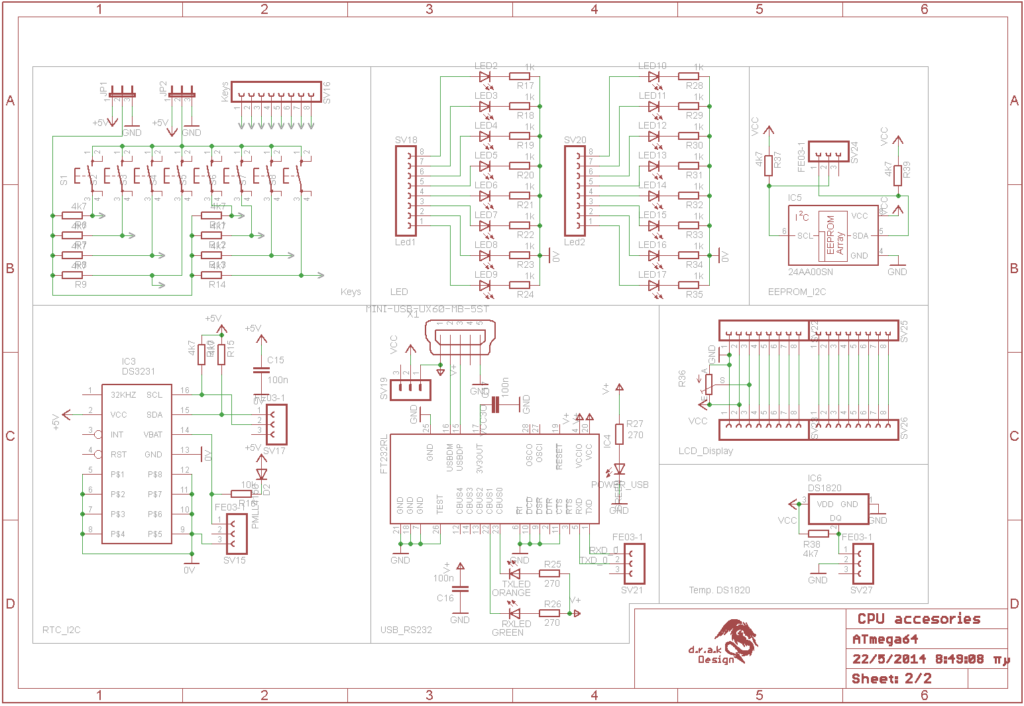

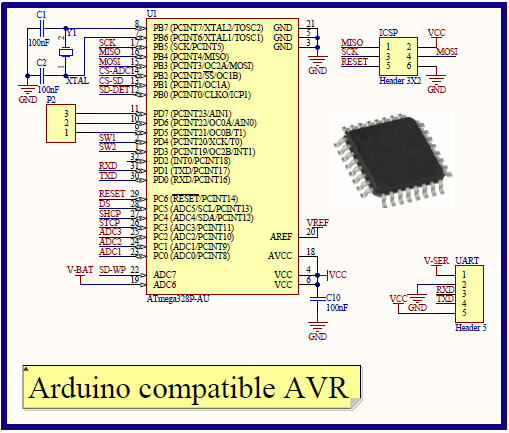

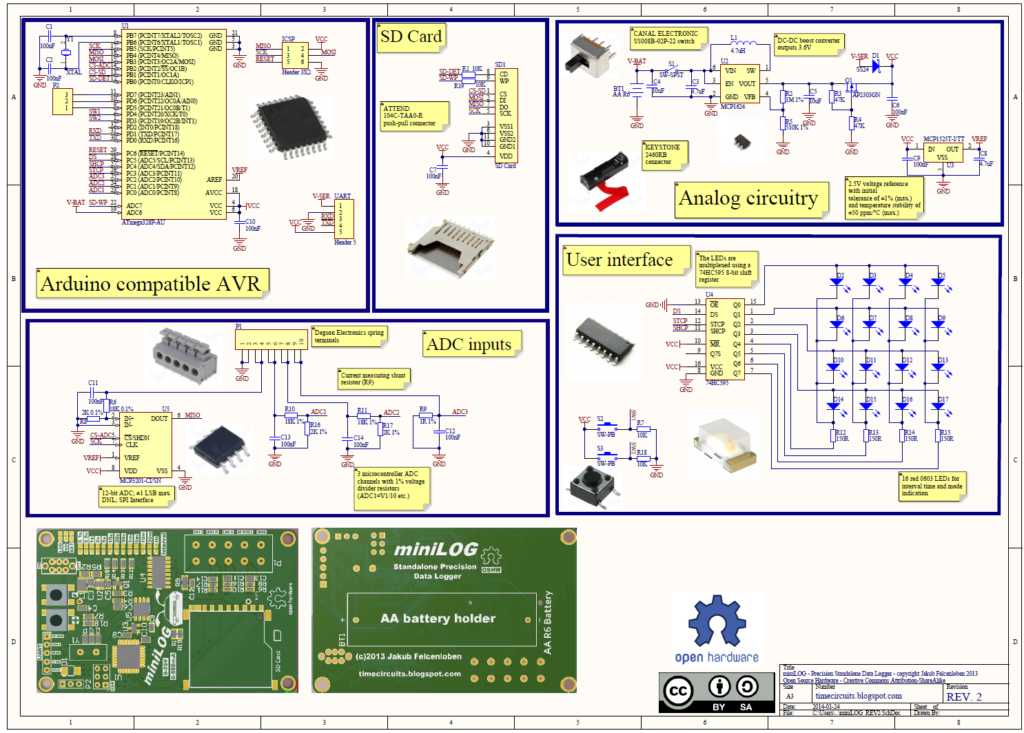

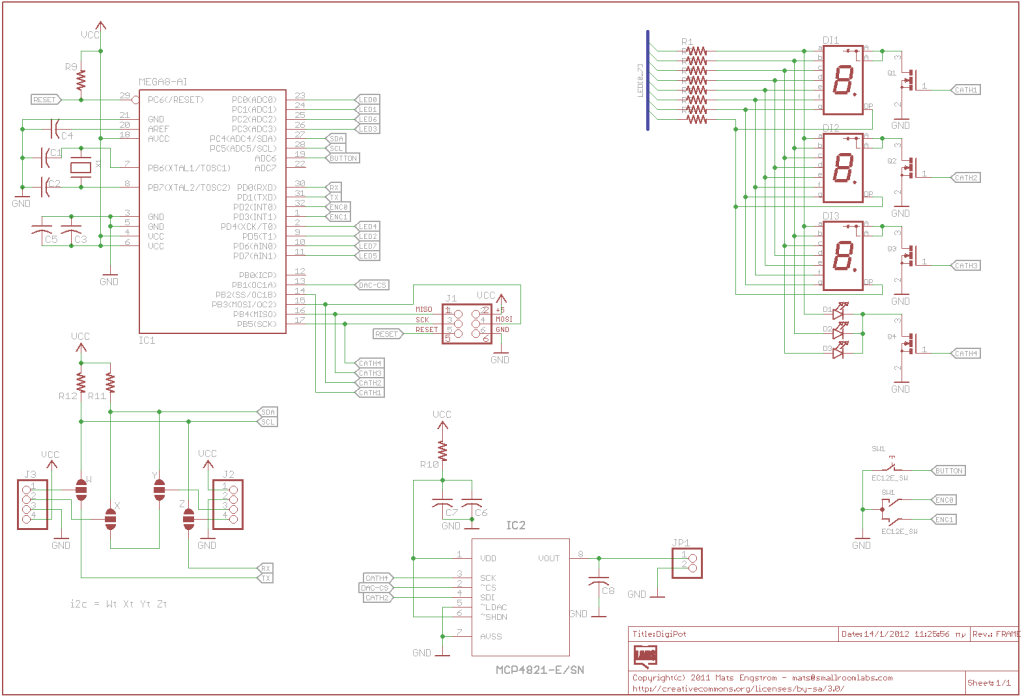

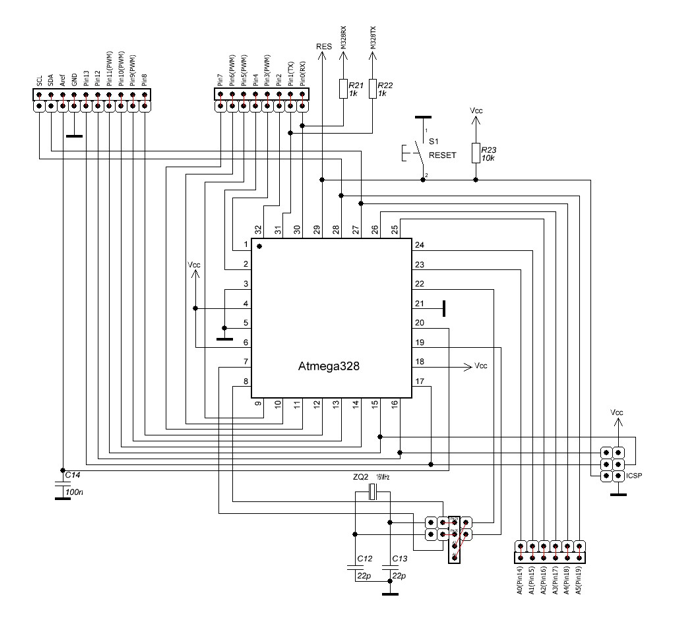

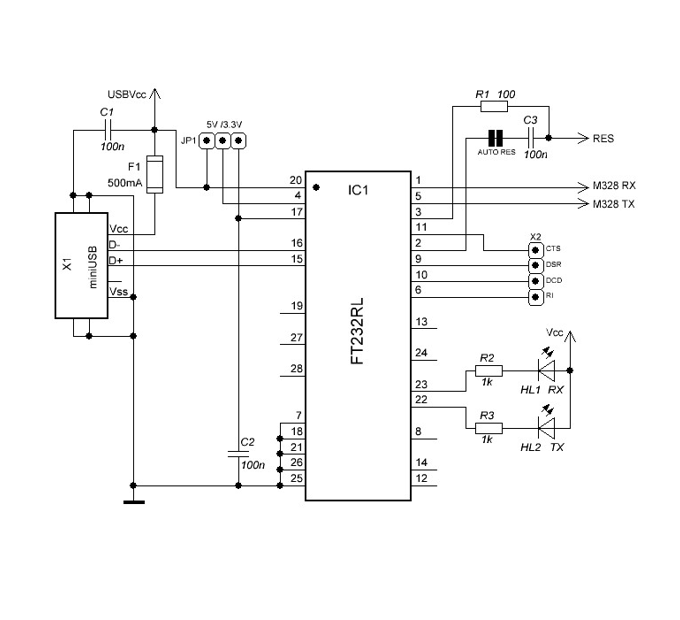

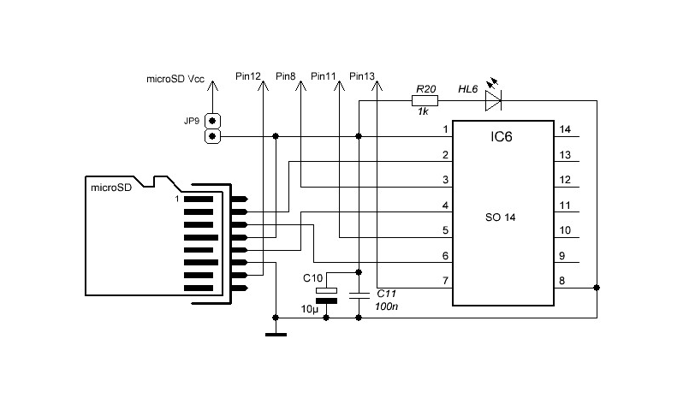

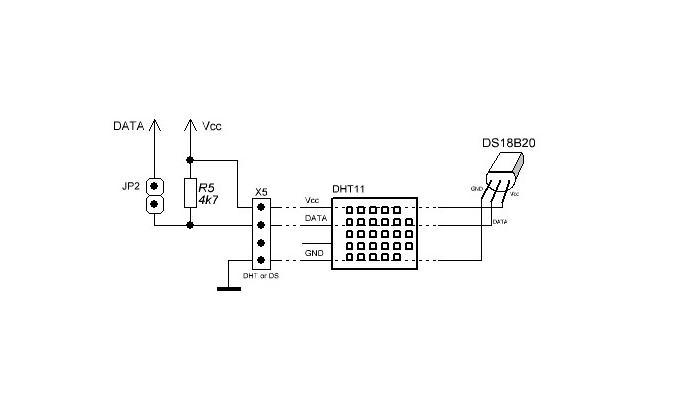

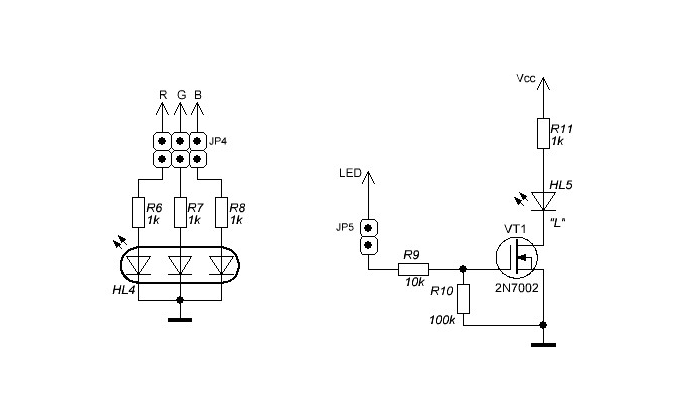

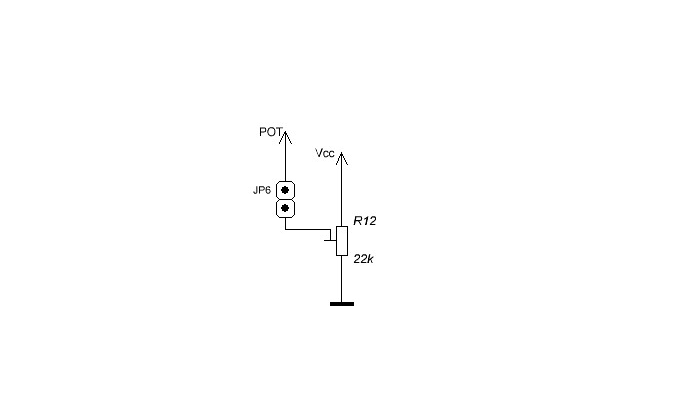

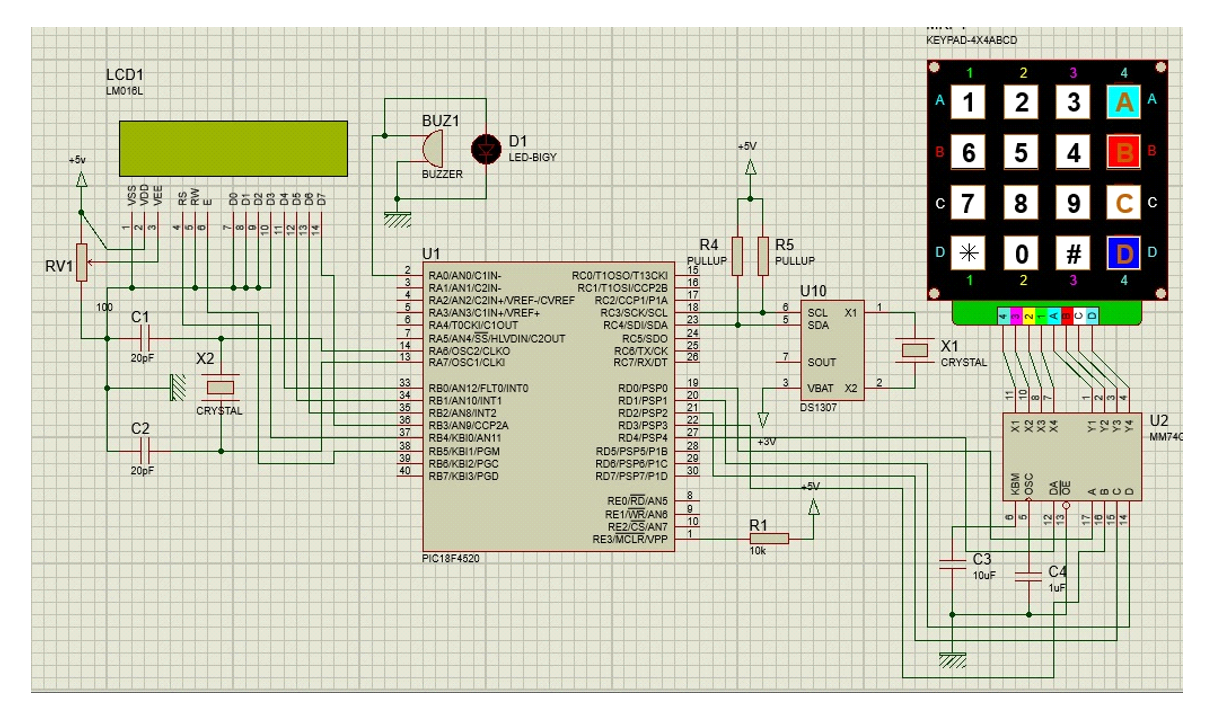

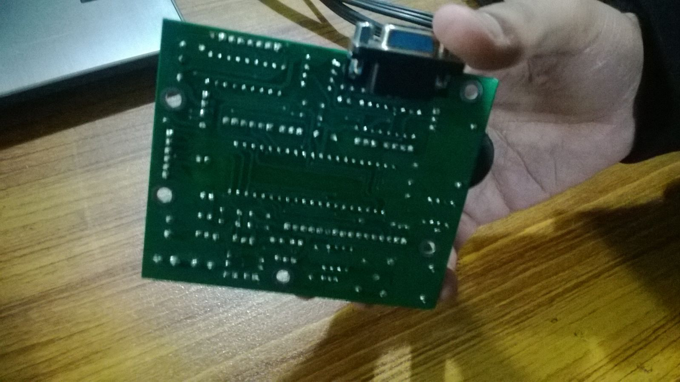

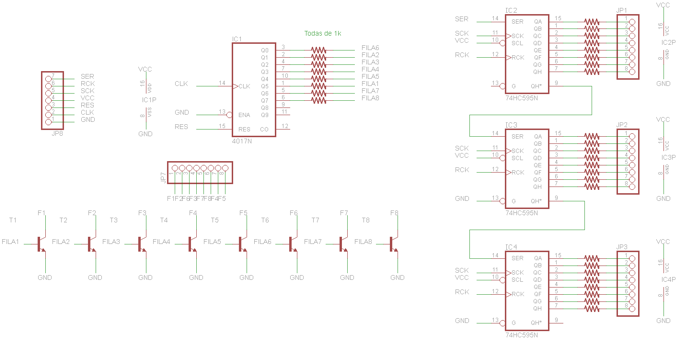

Schematic

To enable the NUC140 CAN peripheral to communicate with CAN bus a CAN transceiver is required. The TJA1051T chip from NXP solves the purpose. The NUC140 device is capable operating from 5V power supply, there is no need for additional 3.3V voltage regulator. This handy combination makes a simple task implementing the CAN bus interface. There are three status LEDs:

- D1 is the status of USB connectivity to the host

- D2 shows the CAN bus activity

- D3 indicates CAN errors

The NUC140 doesn’t have built-in bootloader and the only way to program it is using ARM Serial Wire Debug (SWD) interface (J2 connector) and Nuvoton ICP programmer. And yes, if bootloader is already pre-programmed it could be activated. That is the purpose of JP1 jumper. Connecting the JP1 before powering the interface will trigger the bootloader.

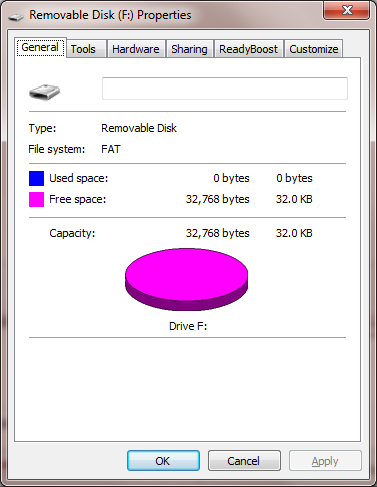

Bootloader

The NUC140LC1 flash memory is divided to two sections, one is for executing user program code (APROM) with the size of 32K and another one for bootloader (LDROM). The LDROM size is only 4K, making a challenge to build a fully-functional USB bootloader. I have used the mass-storage device (MSD) bootloader provided by Nuvoton. Connecting jumper JP1 will start it . As the result a removable drive should be visible in the host file system with a size 32KB. Just copy and paste or drag and drop the CAN-USB firmware update to the bootloader drive. Unplug the USB cable, remove the jumper and plug it in again. The new firmware update should now be running.

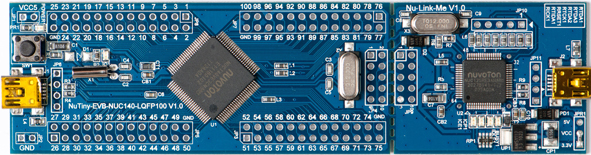

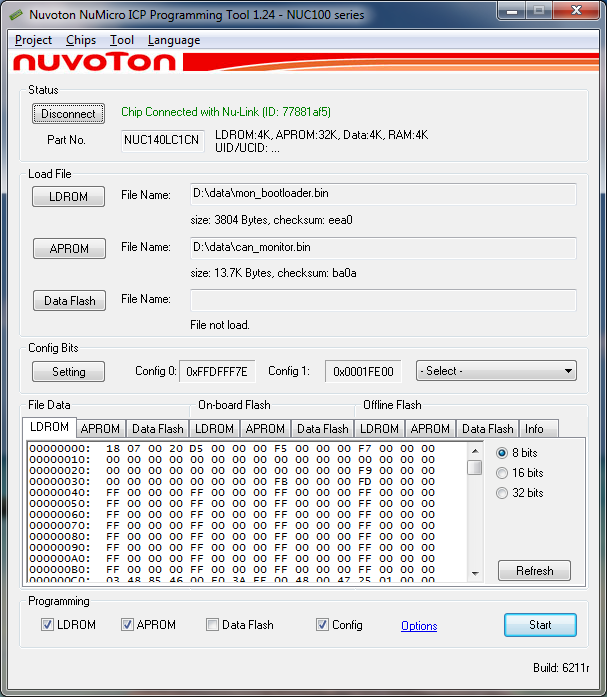

Programming the CAN-USB Interface and NuTiny-SDK-140

Programming the NUC140 processor requires Nuvoton’s Nu-Link programmer and Nuvoton ICP programming application. Instead, I decided to use the NUC140 demo board (NuTiny-SDK-140) available from Digi-Key. It has the two parts, the part with NUC140 chip and Nu-Link programmer itself. The board is even perforated to detach the Nu-Link part. Actually, you can build this device solely around NuTiny-SDK-140 demo board, the only additional CAN transceiver chip will be required.

With Nu-Link connected the programming NUC140 is not complicated. The key issue here is to choose loading from LDROM instead of APROM (in Config settings) to have the USB bootloader functionality.

The Software

The CAN-USB interface is compatible with LAWICEL CANUSB protocol and it will work with the applications built for it. The are two application I have tested with the CAN-USB interface:

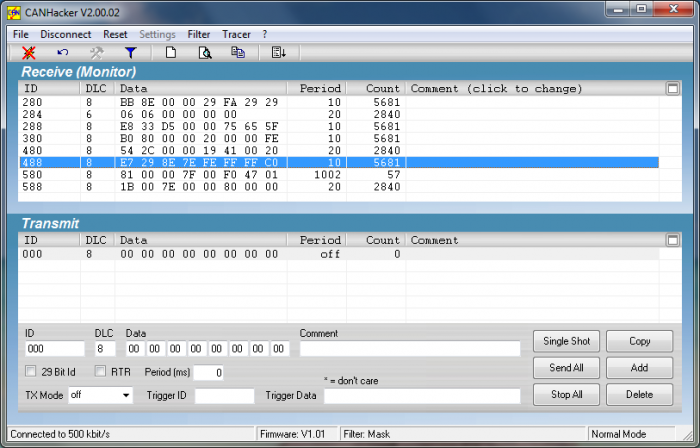

CANHacker V2.00.02

The CANHacker application is freeware. I was unable to find the manual for it, but using it is simple and straightforward.

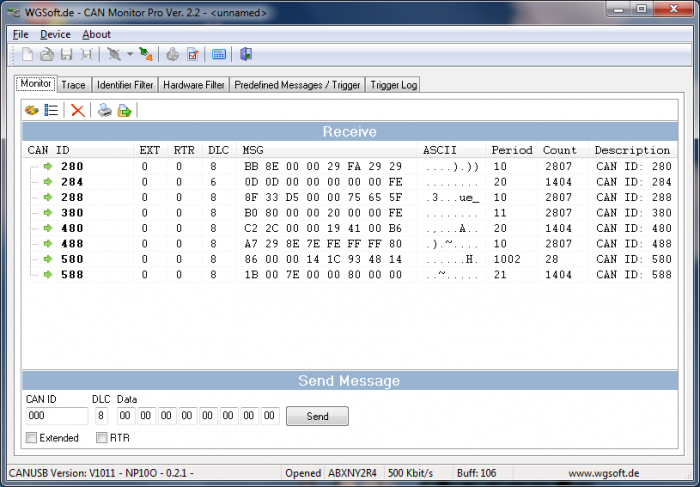

CAN Monitor Pro V2.2

This application is made by wgsoft.de. Note, that the site is mostly in German.

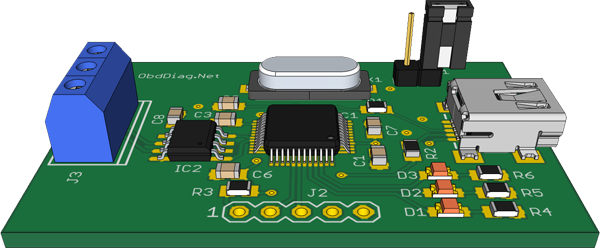

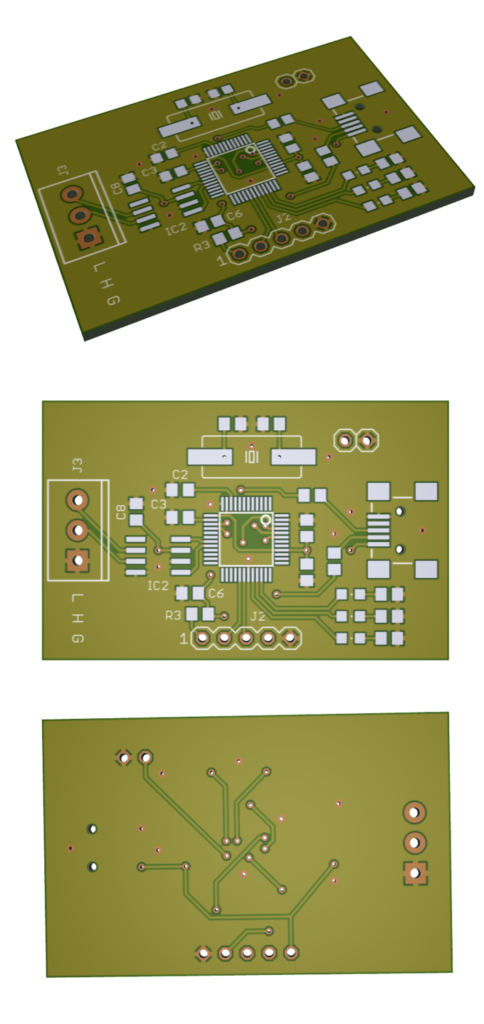

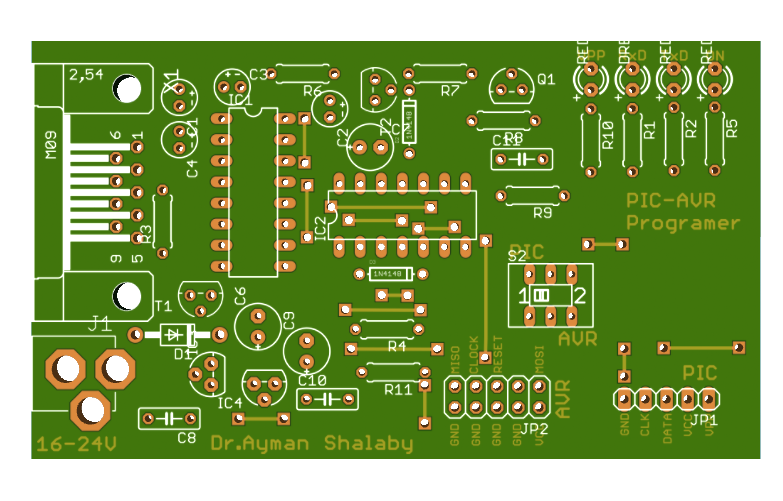

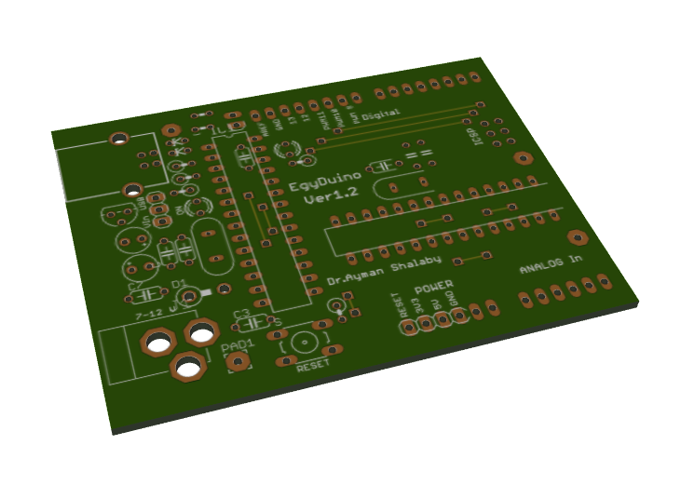

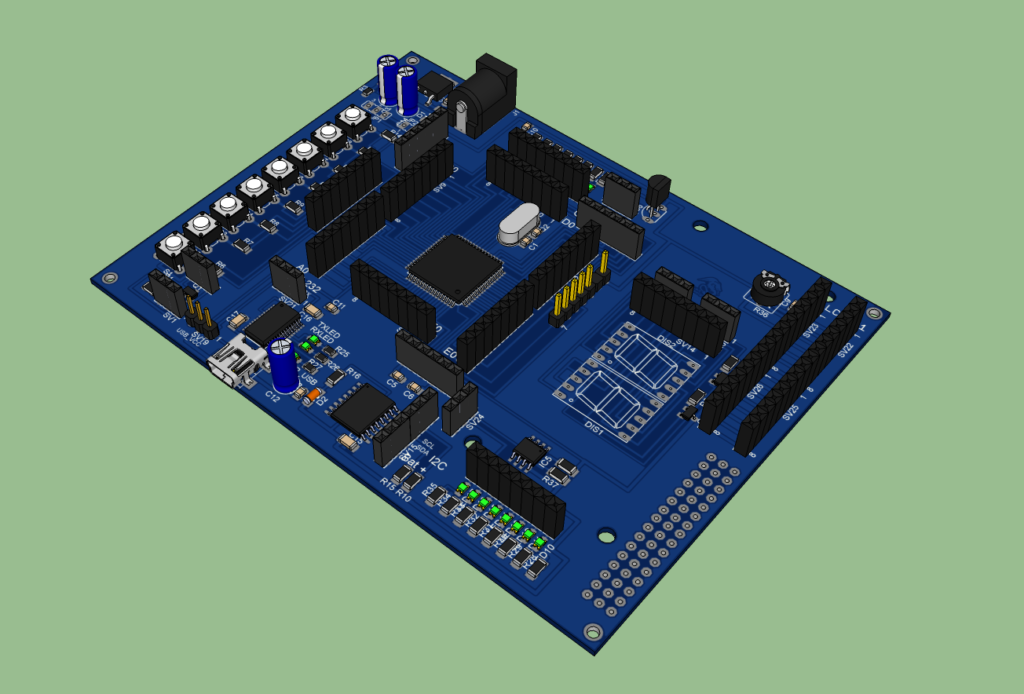

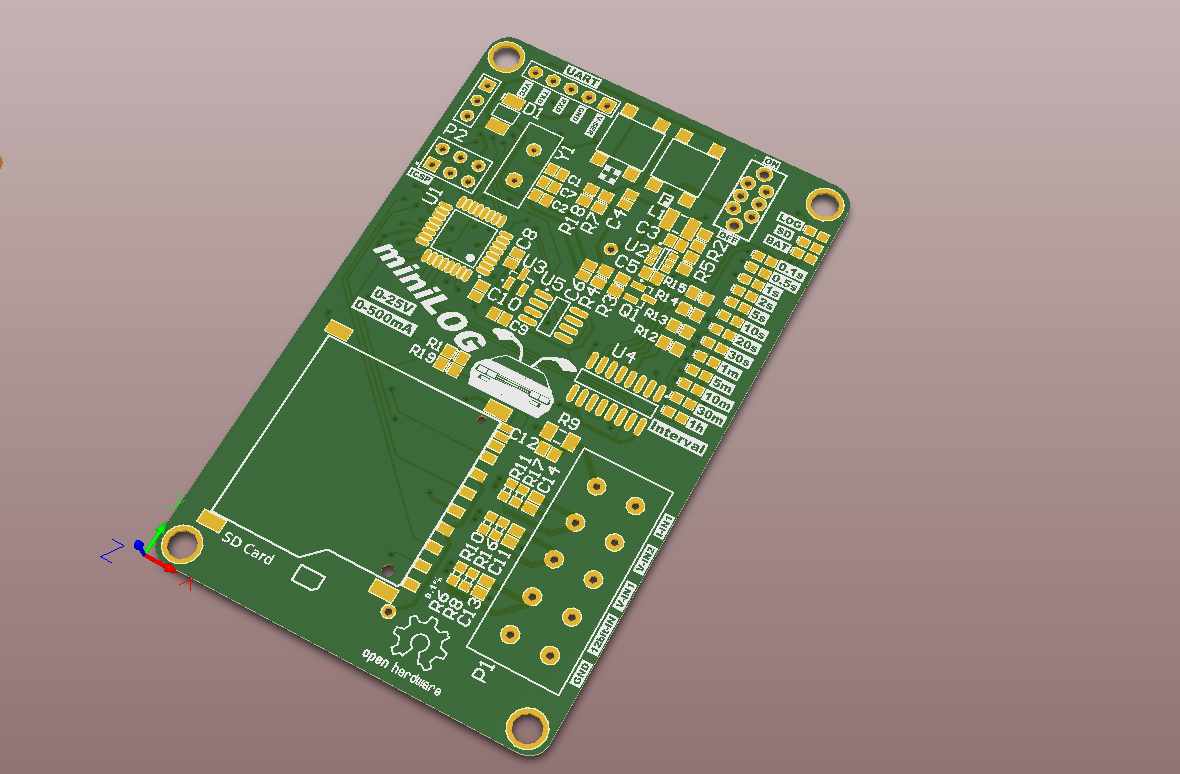

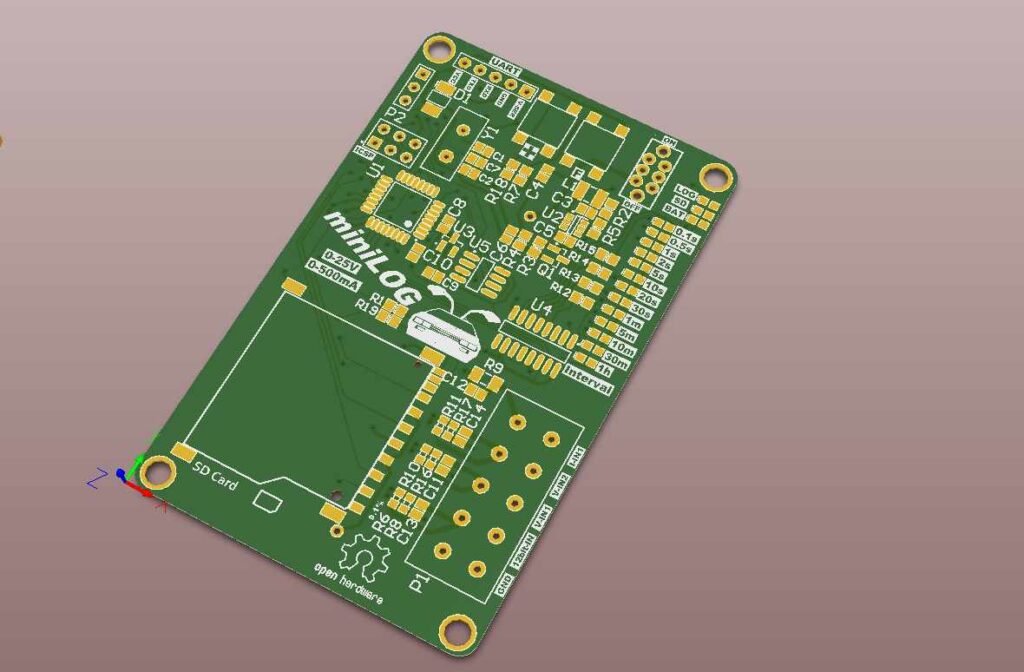

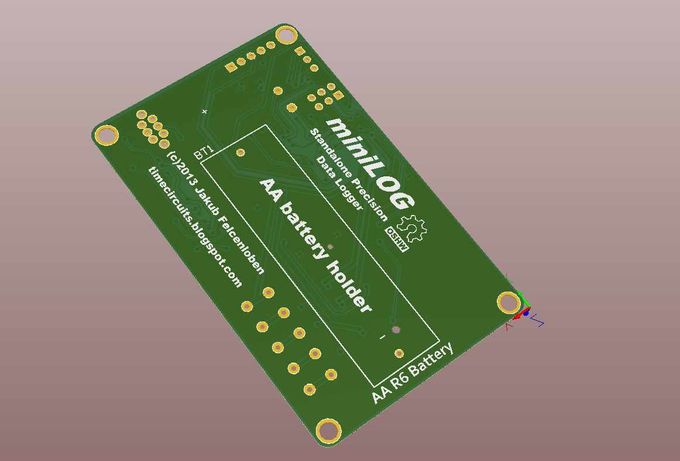

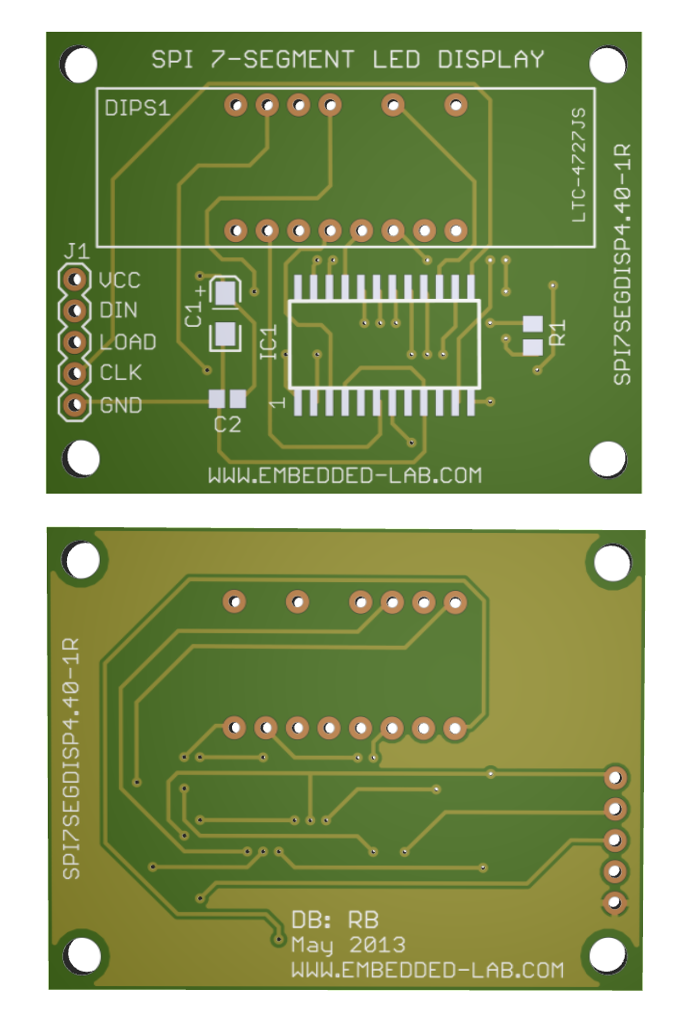

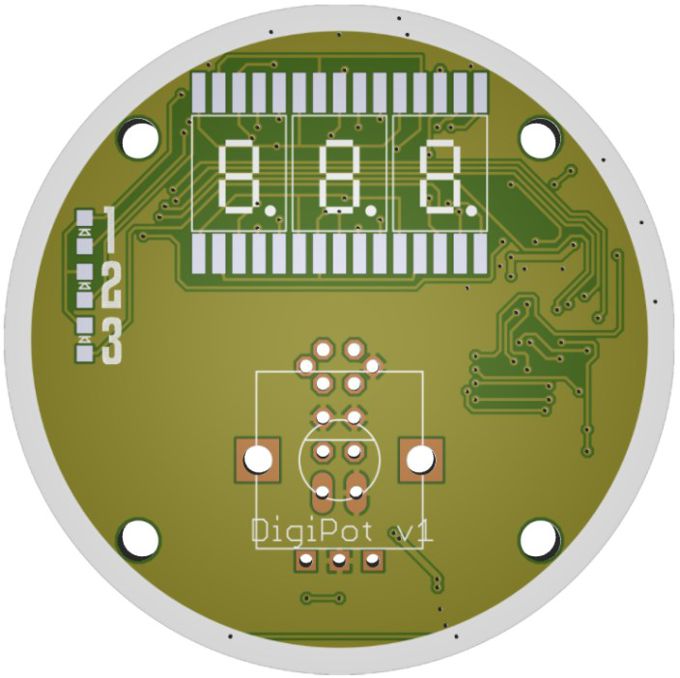

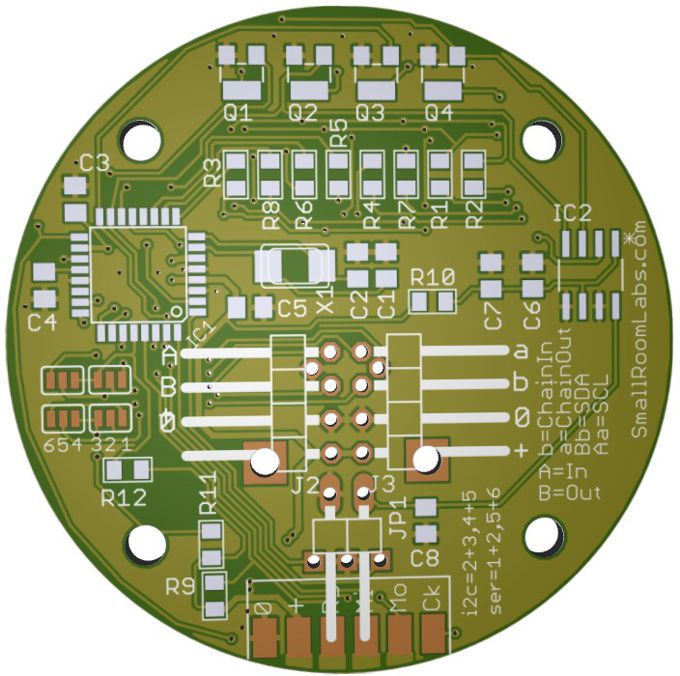

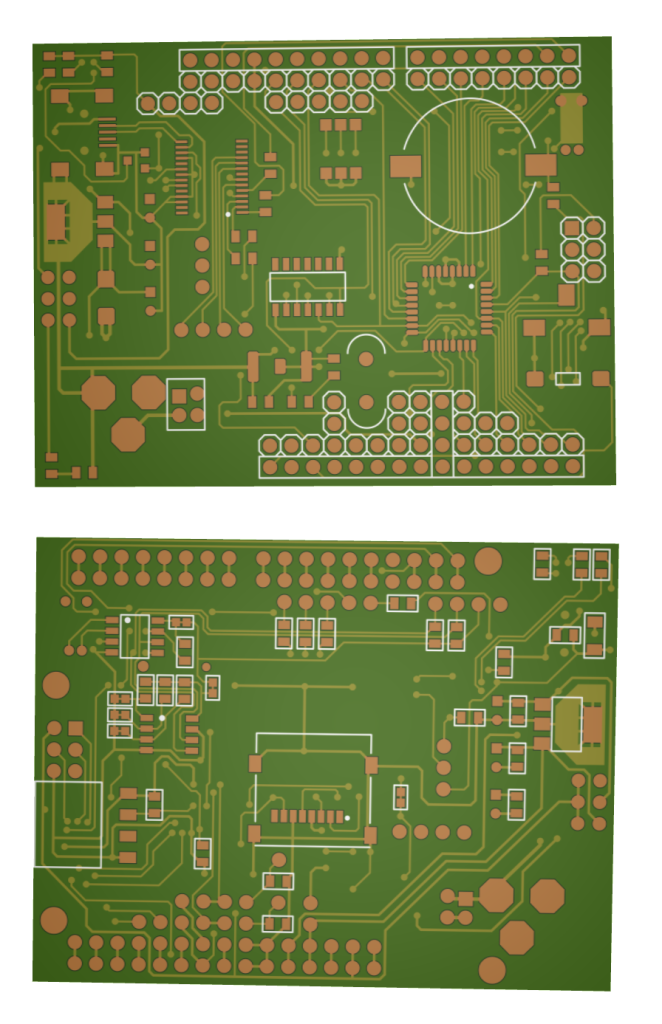

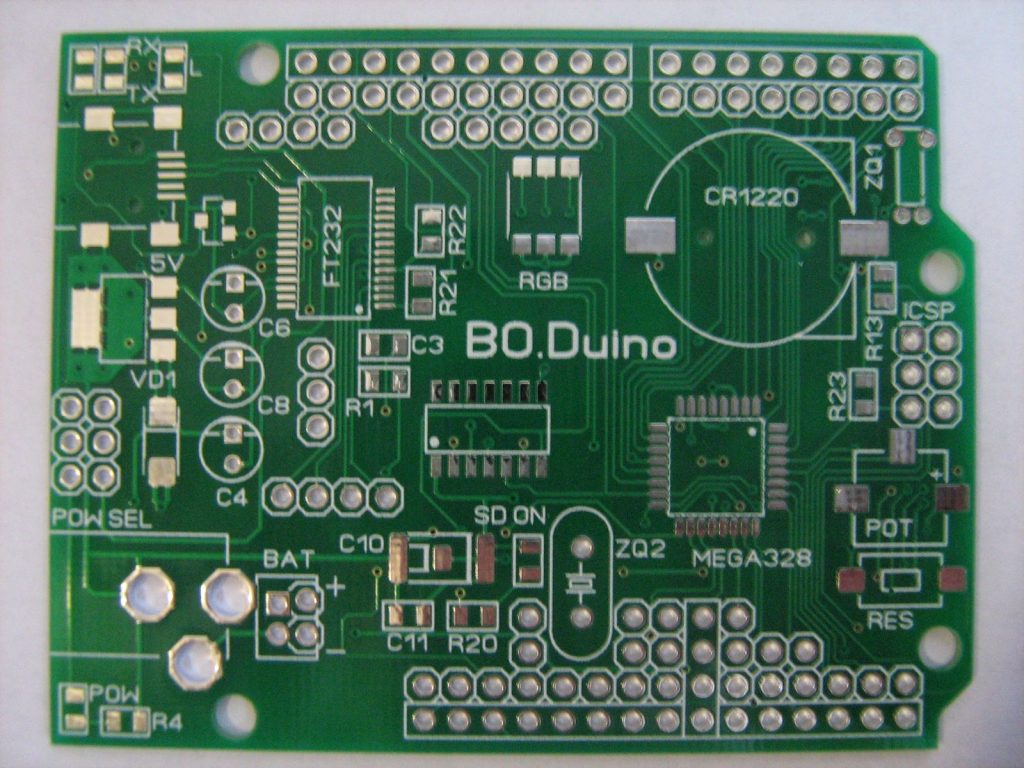

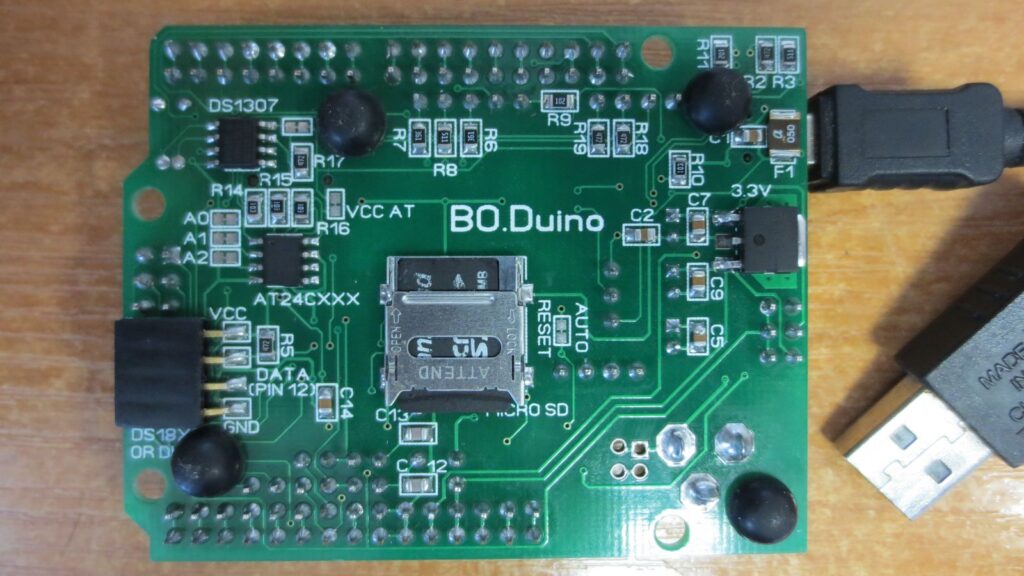

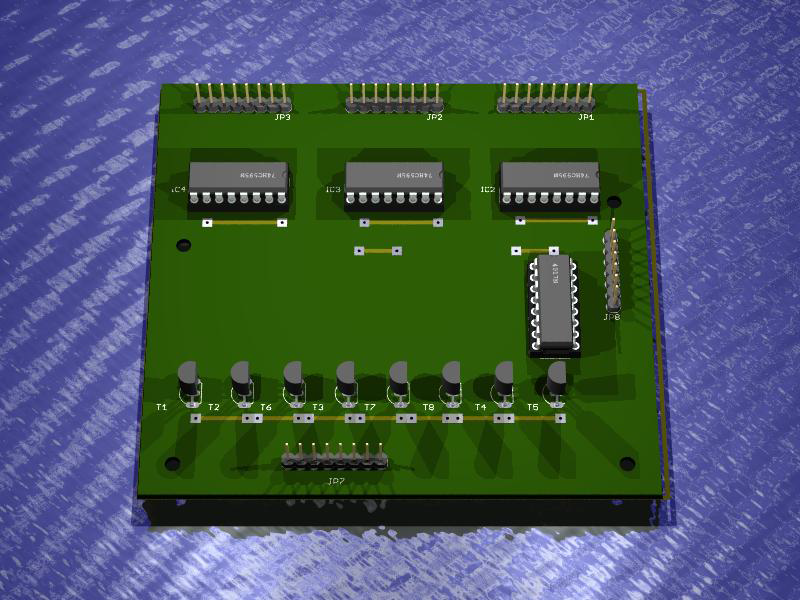

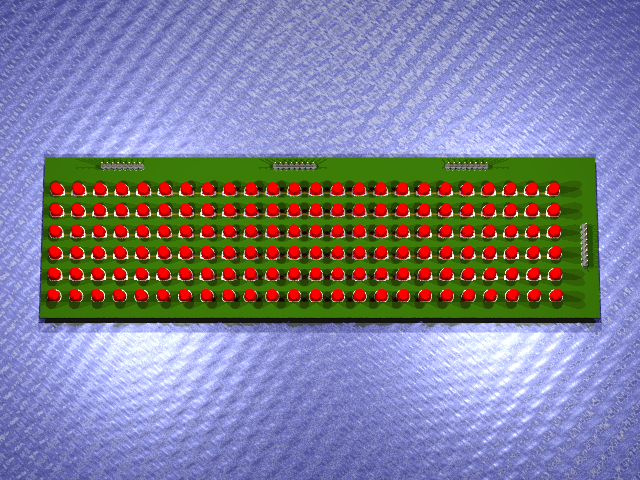

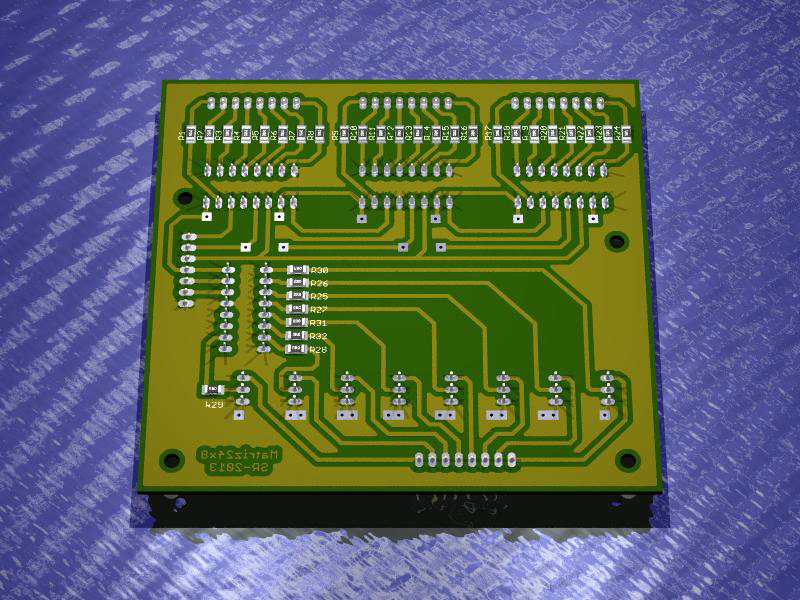

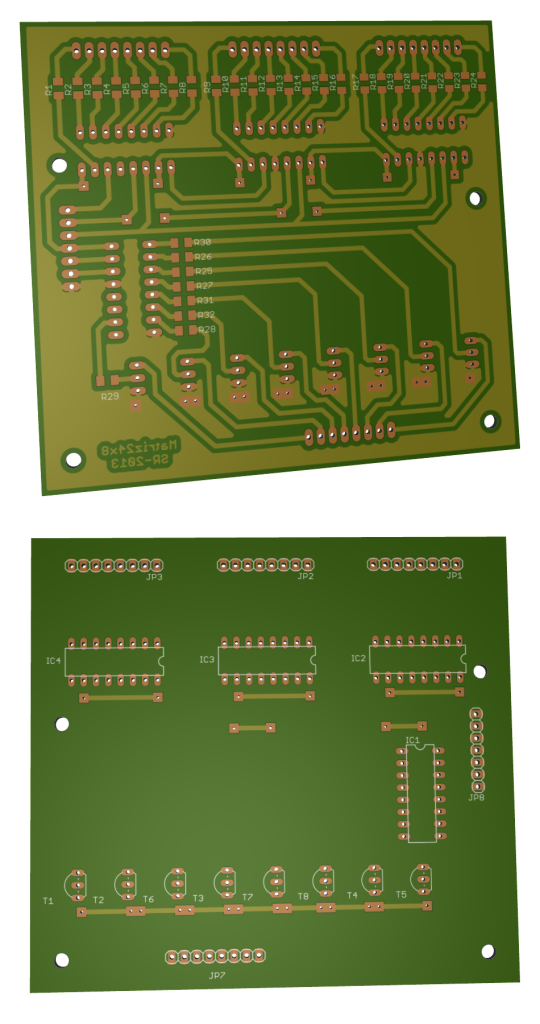

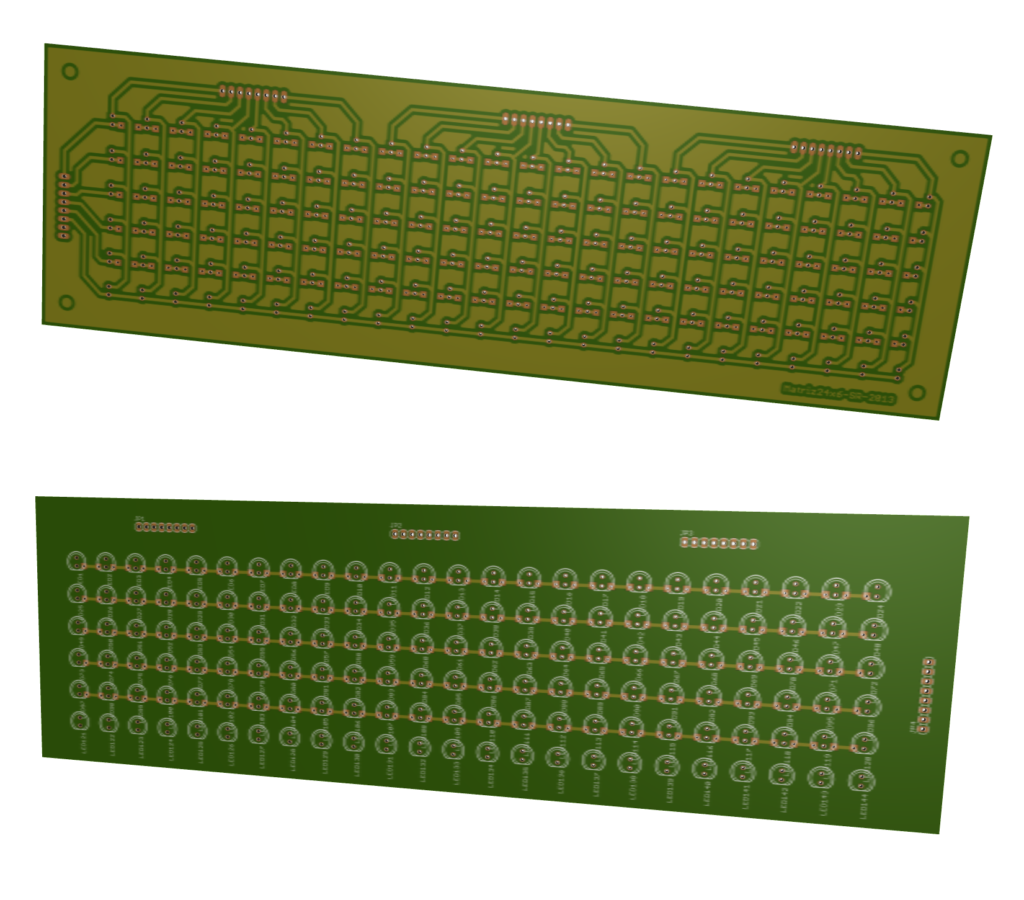

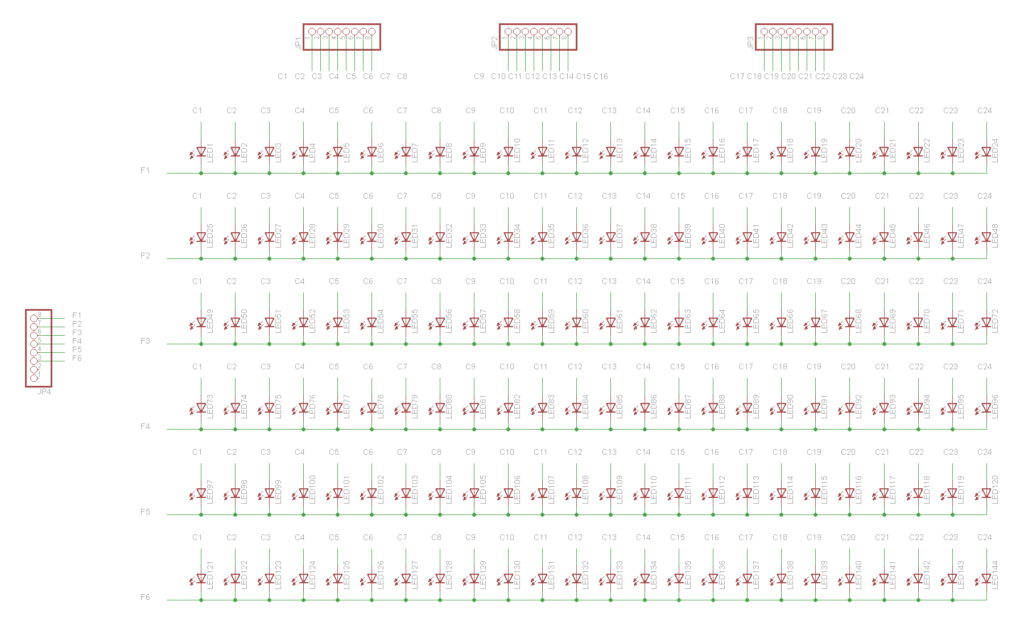

PCB Design