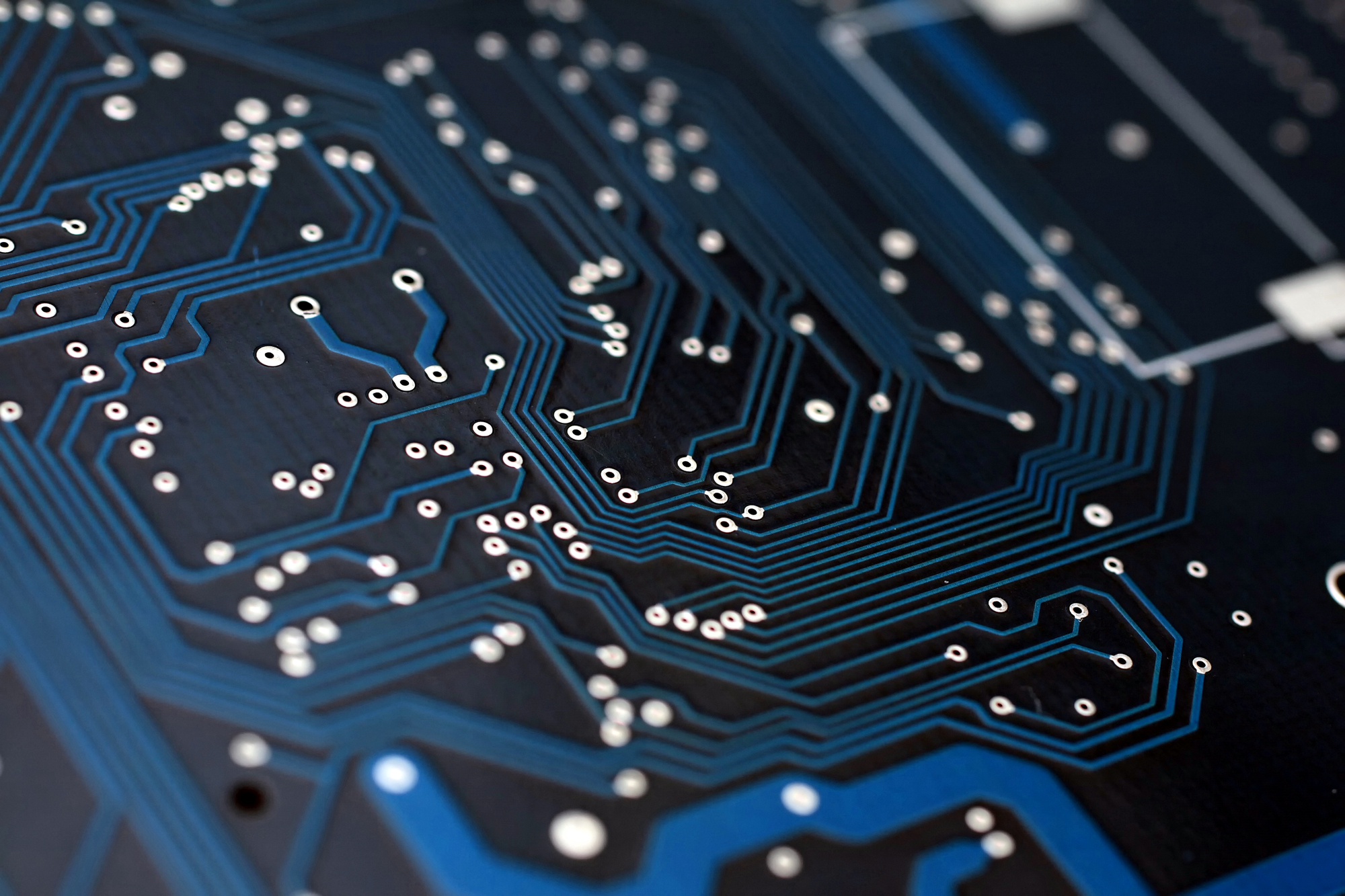

Printed Circuit Boards (PCBs) are popular among engineers, developers, and hobbyists and they are readily available for use in many devices that we use in our daily lives. You can find them in portable electronic devices, industrial machines, heavy equipment, communication devices and consumer electronics. The PCBs we see today are usually very complex and comprised of different shapes and materials. Some are flex and rigid, and have variety of components that are wired together to perform a specific task. PCBgogo is an experienced PCB manufacturer that provides turnkey service for PCB assembly prototype and small-batch PCB fabrication. They offer various types of PCBs, fabrication service, and in this article we will talk about 3 different types.

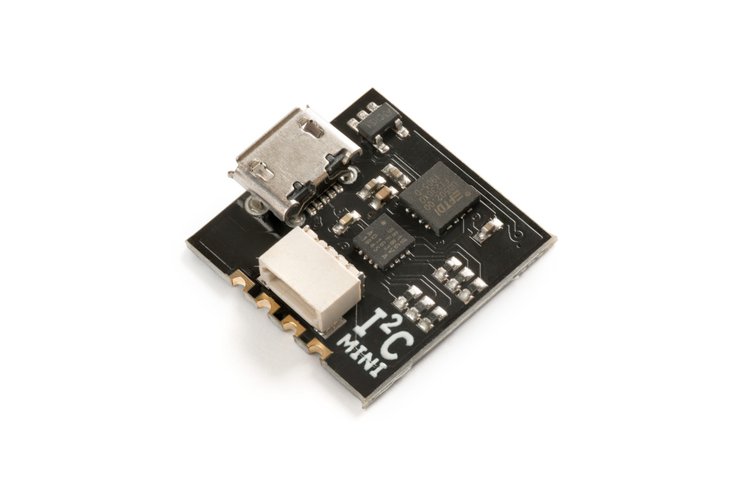

Multilayer PCB

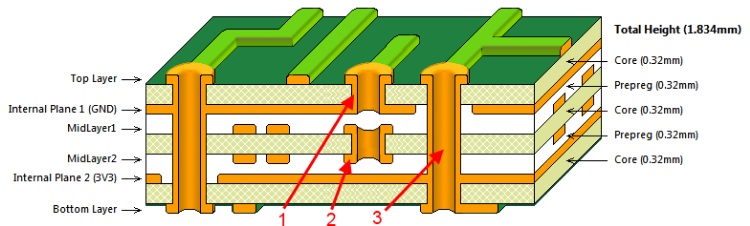

A multilayer PCB is ta PCB that has multiple layers of copper, which is laminated and joined together, and then the components are soldered on top and bottom sides. The inner layers are actually the double sided circuit that are combined with each other to form one thick PCB with multilayers. The components are electrically connected via copper tracks and vias, and pads/ holes link the interconnections. The vias are of different types like PTH, blind and buried. The result is the complex PCB with maximum circuitry on smaller PCB size.

Due to complex processing and evolving technology, demands for PCB layout procedure that can achieve the desired requirements are needed. Also the problems that were occurring in the single or double sided PCBs like noise and stray capacitance was also an issue that caused the invention of multilayer PCB. Multilayer PCBs are usually available from 4 layers to 12 layers, depending on the application and requirements. The layers are usually in even numbers like 4 layer PCB or 8 layer PCB, this is because the odd numbered layers will cause problems of circuit wrapping and similar type issues. The multilayer PCBs are costly to produce compared to single sided because of the extra steps involved during PCB fabrication, however their application are very huge. For example a smartphone can feature a PCB with up-to 8 layers and a military electrical equipment can feature a PCB with up-to 100 layers. This type of PCB with so many layers are very rare and costly.

What are some of the advantages of multilayer PCBs?

- Miniature Size: Multilayer PCB is small in size. The size is reduced due to multiple layers being stacked on each other, and connected by “vias”. This enables more compact, dense, solid and smaller sized PCBs. We can find multilayer PCBs being used in mobile phones, laptops, and wearable electronics.

- Less weight: Because of its small size, multilayer PCBs are usually light weight and can be easily portable and used in handheld electronics.

- High-Quality: Multilayer PCBs offers high quality, because they are fabricated in a very well organized manner, and the amount of effort and work load put into their fabrication is definitely more than that of single or double layer PCBs. Hence more quality and reliability results.

- Durability: High pressure is applied to bind the multiple layers with each other. The high temperatures and heat environment through which these PCBs go during fabrication process and bonding agent and protective layers make these PCBs solid, strong and durable.

- More Density: Multilayer PCB offers higher density compared to its counterpart single and double sided PCBs. This is because the density of a PCB is directly proportional to the number of components soldered on a per unit size of PCB. For example 20 components placed on per square inch of PCB is denser than the PCB having 15 components per square inch.

- More Functionality: Due to its high density, more circuitry is incorporated in lesser PCB space. Therefore, more computing and more powerful and speedy architecture is possible. This is highly demanded in high computation electronics like quantum computing, artificial intelligence, crypto currency mining machines, graphic cards and super computers

- Ease of Installation: In many old electronic types of equipment like tvs, we see that the power supply section, video processing section, and display driver sections are all fabricated on separated PCBs, and they are integrated with each other via different connectors and sockets and complex wiring required. However reverse is the case today. Modern LED TV comes in a PCB that has the power supply, LED driver circuit, and mother board all incorporated on a single PCB and a single point of connection is required to install in the enclosure and lesser wiring/harness is required. This helps in ease of installation and dismantling the unit when repairs and troubleshooting is required.

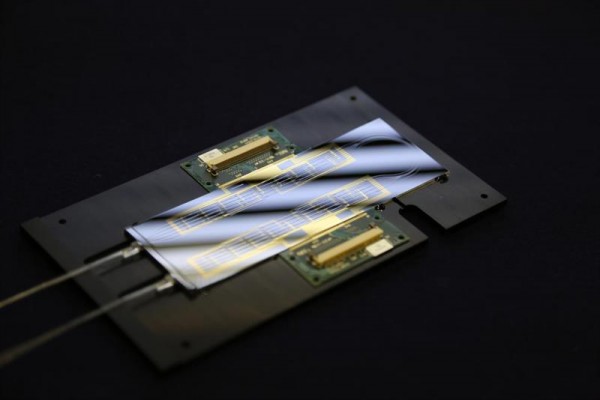

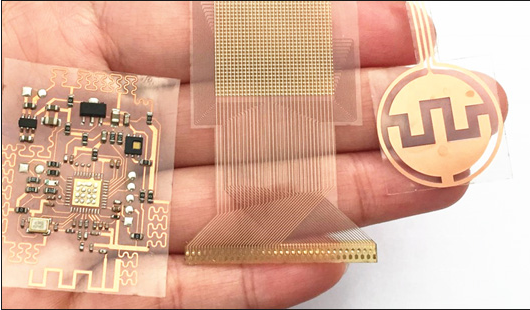

Rigid-Flex PCB

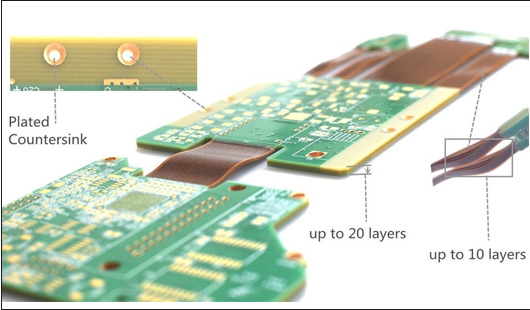

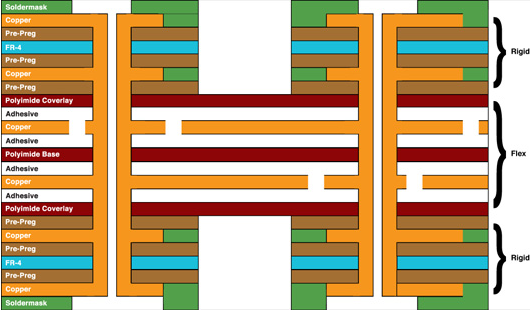

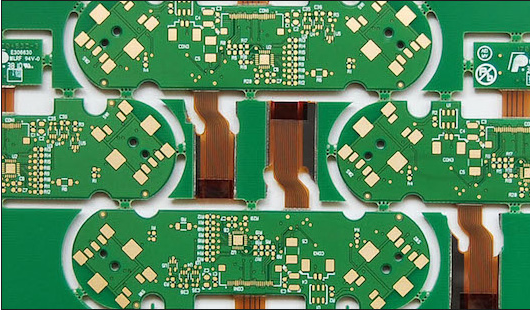

Another PCB service PCBgogo offers is the rigid-flex printed circuit board. What are rigid-flex printed circuit boards? They are the composite boards of rigid boards and flexible boards. When you examine most rigid-flex circuits, you realize that they are multi-layered. However, a rigid-flex PCB can house one or several flex boards and rigid boards, which are then connected through internally/externally plated-through holes.

Rigid-flex PCBs have a thin profile and feature variable shapes. This makes it suitable for ultra-thin and ultra-light packages. Can solve many problems in traditional hardboard technologies. Rigid-flex PCBs make it easier to install more components in a smaller space because they can change the shapes according to specific outlines. This helps reduce the size and weight of the final products and overall system costs. Also, the compact profile of rigid-flex PCB makes it the ideal choice for fine line and high-density circuits in HDI technologies.

Rigid-flex PCBs also offer freedom in packaging geometry. This makes is it suitable for applications in various industries like aerospace, military, medical equipment, and consumer electrics. The rigid-flex PCBs can be customized to any size or shape to fit the housing designs and 3D designs, enabling designers to meet different requirements in specific applications.

Rigid-flex PCBs also offer better mechanical stability due to the stability of rigid boards and the flexibility of flexible boards. This forms a stable structure for the entire package while retaining the reliability of the electrical connection and flexibility needed for installation in small spaces.

Rigid-flex PCBs perform greatly under harsh environments. They have high shock and high vibration resistance so that they can work well in high-stress environments. They also feature fewer cables and connectors, thereby reducing safety risks and maintenance in future use.

Rigid-flex PCBs require fewer interconnectors and related components/parts. It helps to simplify the assembly operations, making the rigid-flex PCBs easier to be assembled and tested. Rigid-flex PCBs are very suitable for PCB Prototypes.

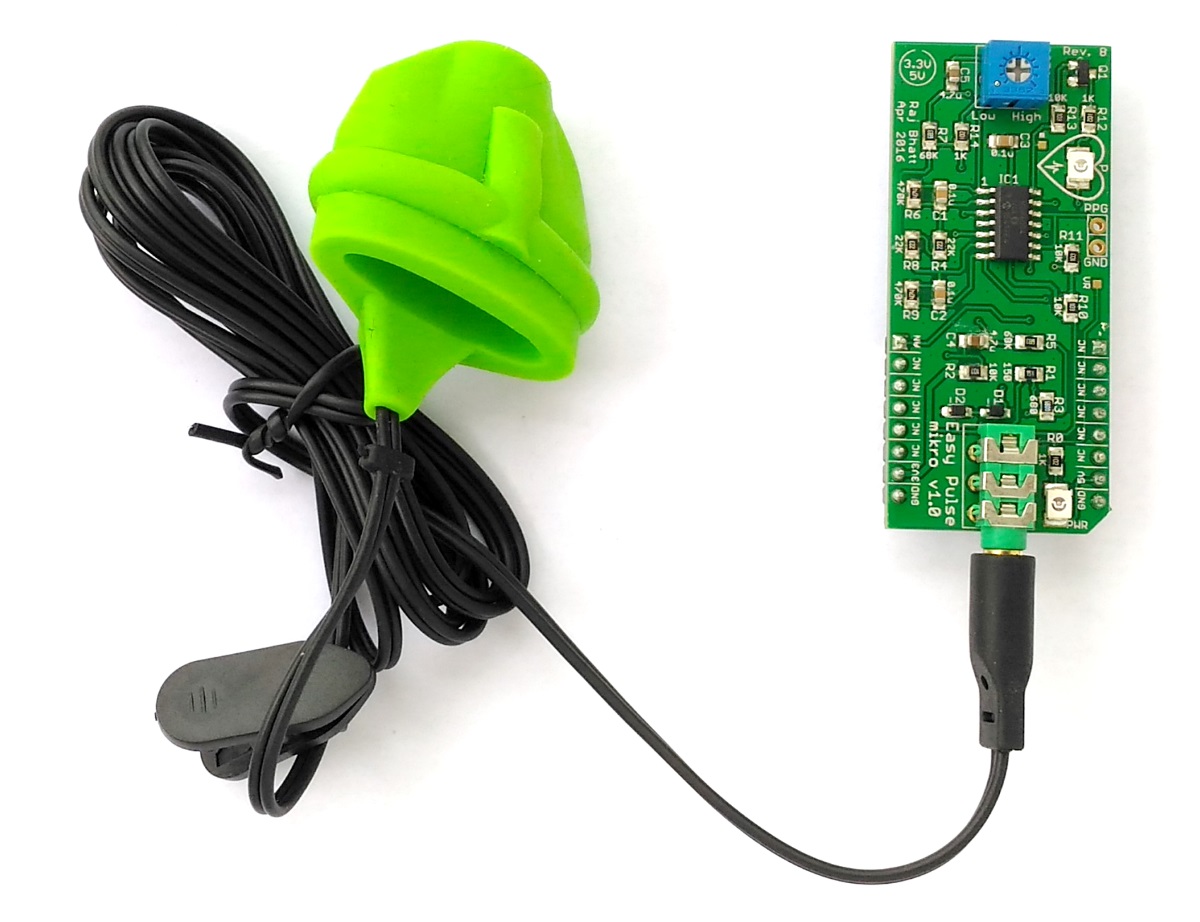

Flexible PCB (FPC)

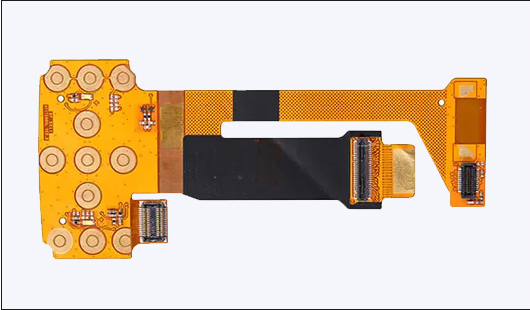

Flexible PCBs (FPC) are PCBs that can be bent or twisted without damaging the circuits. This means the boards can be bent freely to conform to any desired shape during applications. Flexible materials, such as Polyamide, PEEK, or conductive polyester film are used to create these PCBs. When you examine the dielectric layers in FPCs, you see that they are typically homologous sheets of flexible polyimide material. While The dielectric materials in rigid PCBs are usually the composite of epoxy and glass fiber woven cloth. In many PCBs, you can find a layer of solder mask on both sides. The solder mask has gaps, and the SMT pads or PTH holes are exposed to enable components to be assembled. However, in the case of FPC, you find a cover coat instead of a solder mask. The cover coat is a thin polyimide material that can be drilled or laser-cut to access the components.

The manufacturing process of FPCs and rigid PCBs are similar. But FPCs need special tools to hold them in a fixed position because of their flexibility. Regarding price, FPCs are more expensive than rigid PCBs, however, they offer many benefits like improving the cost performance, space-saving, weight-reducing, and high reliability, etc. FPCs offer many benefits. You can find them as connectors in various applications. Due to its excellent flexibility, you can extend the service life of the circuits and save much space. You can find applications of FPCs in smartphones and medical equipment that require many interconnections in a compact package.

Another advantage of FPCs is that they are lightweight and have a smaller volume than rigid PCBs and can be designed to smaller sizes for its flexibility. This makes FPCs ideal to replace bulky circuits in some applications. FPCs offer better resistance and movement performance. They are easy to wrap without breaking and damaging, making them very suitable for outdoor electronics, sports equipment, and wearable electronics.

FPCs have no mechanical connectors during applications. This improves durability in harsh environments. It also enables better heat dissipation than rigid PCBs. This makes it suitable for application in computer components, televisions, printers, and gaming systems.

Even though Flexible PCBs have so many unique advantages in various applications, they still cannot replace rigid PCBs. PCBgogo has a strict quality control system to ensure that the PCBs are manufactured and assembled correctly with high-quality standards.

Visit their website today to order your new PCB.

[cover photo by www.depositphotos.com]