Pressure sensors are used today in many fields, such as automotive industry, touch screen devices, aviation and biomedical instrumentation, many of these applications require precise and accurate measures. Many times, this can not be achieved because of the limitations of the sensors such as the inability to measure on round surfaces (if they are twisted or wrinkled). To solve this problem a transparent and bendable nanofiber sensor was developed.

The sensor contains organic transistors and electronic switches which are made from carbon and oxygen based materials, this makes the sensor capable of bending over a radius of 80 millimeters, measuring in 144 locations simultaneously. It is only around 8 micrometers thick, and it’s not sensitive to distortion.

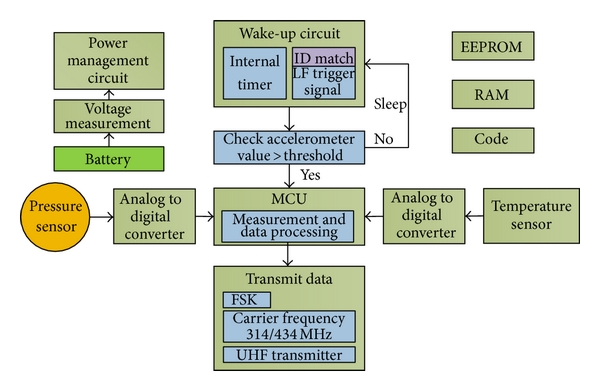

Additionally, the pressure sensor is transparent and small, so it can be incorporated in wearables and implants. Wearables have been developed to shorten hospitals visits, to keep track of chronic diseases and for older citizens who do not want to live in assisted living facilities. Wearable technologies are capable of sensing different parameters of various diseases and transfer the data to a health center or directly to the patient, so they can take actions regarding their health. This technology improves the life quality of many patients, and can stay on for really long periods of time. Also, the main objective of wearables is to go unnoticed by both the patient and other people which is why the developed pressure sensor needs to be capable of bending, and adapting to a person´s constant moves.

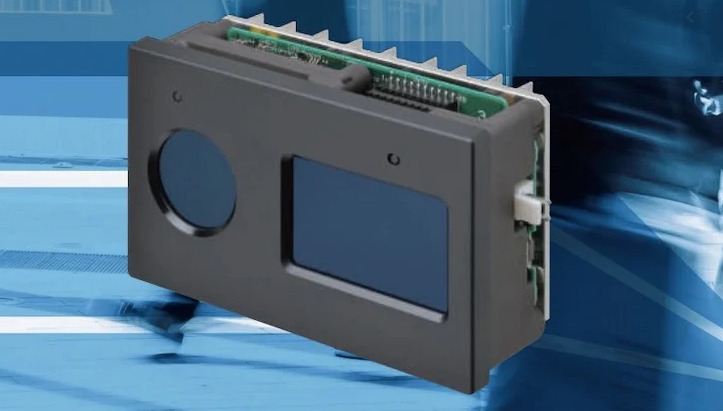

Many applications have arisen from this project. For example, this device could allow breast tumor detection avoiding uncomfortable mammographs, and invasive biopsies. Also, it can be used to detect pressure and speed of blood allowing easy and superficial examination and diagnosis. Woman could now be cancer tested from home, and people who suffer from cardiac or blood pressure diseases could now be monitored away from the hospital.

The flexible nanofiber was created by combining carbon nanotubes, graphene and elastic polymers which makes the sensor really accurate even when stretched and deformed. Many companies are developing sensors with the same capabilities, but this is the first one which is not sensitive to distortion. Even though the researchers are only looking toward improving biomedical industry, the applications for this pressure sensor could be expanded to many industries. There is still a long way to go to achieve this objective, but this sensor is the first step, and health industry its a great place to start.