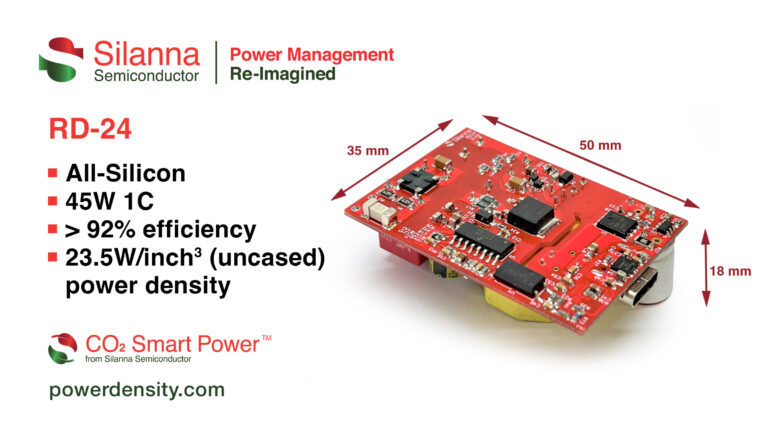

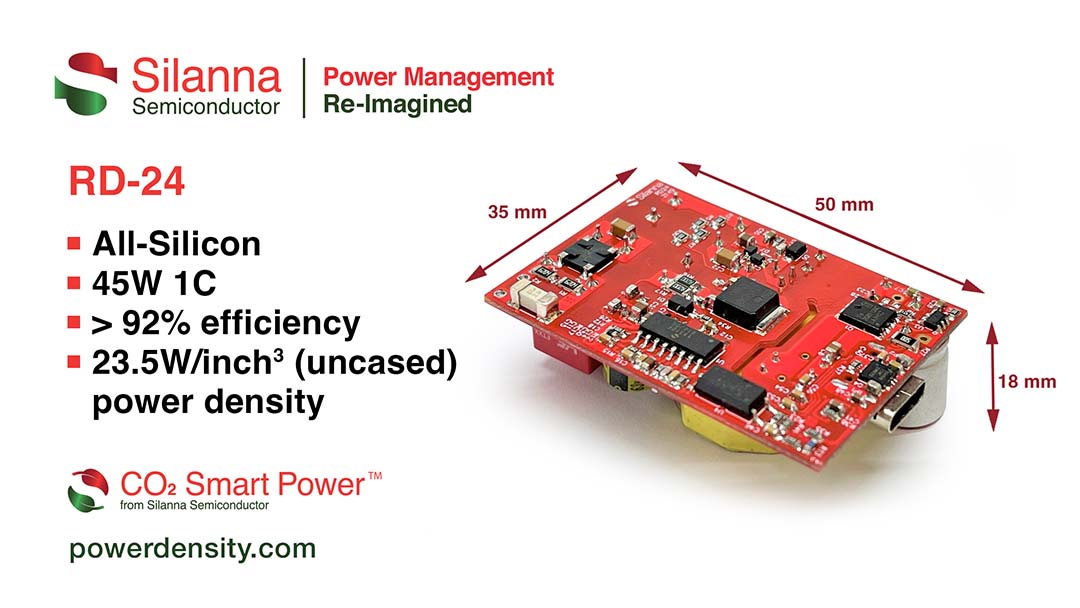

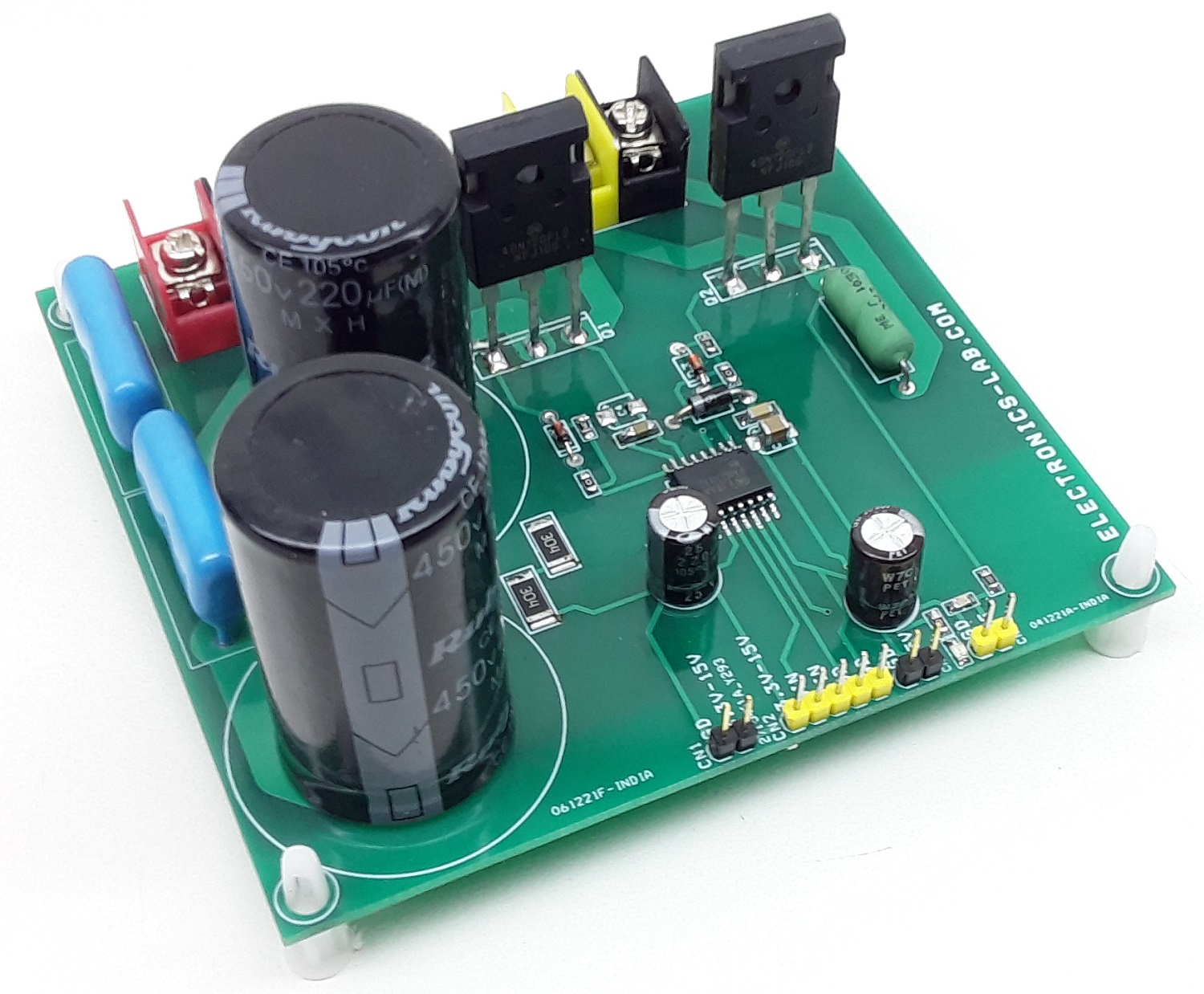

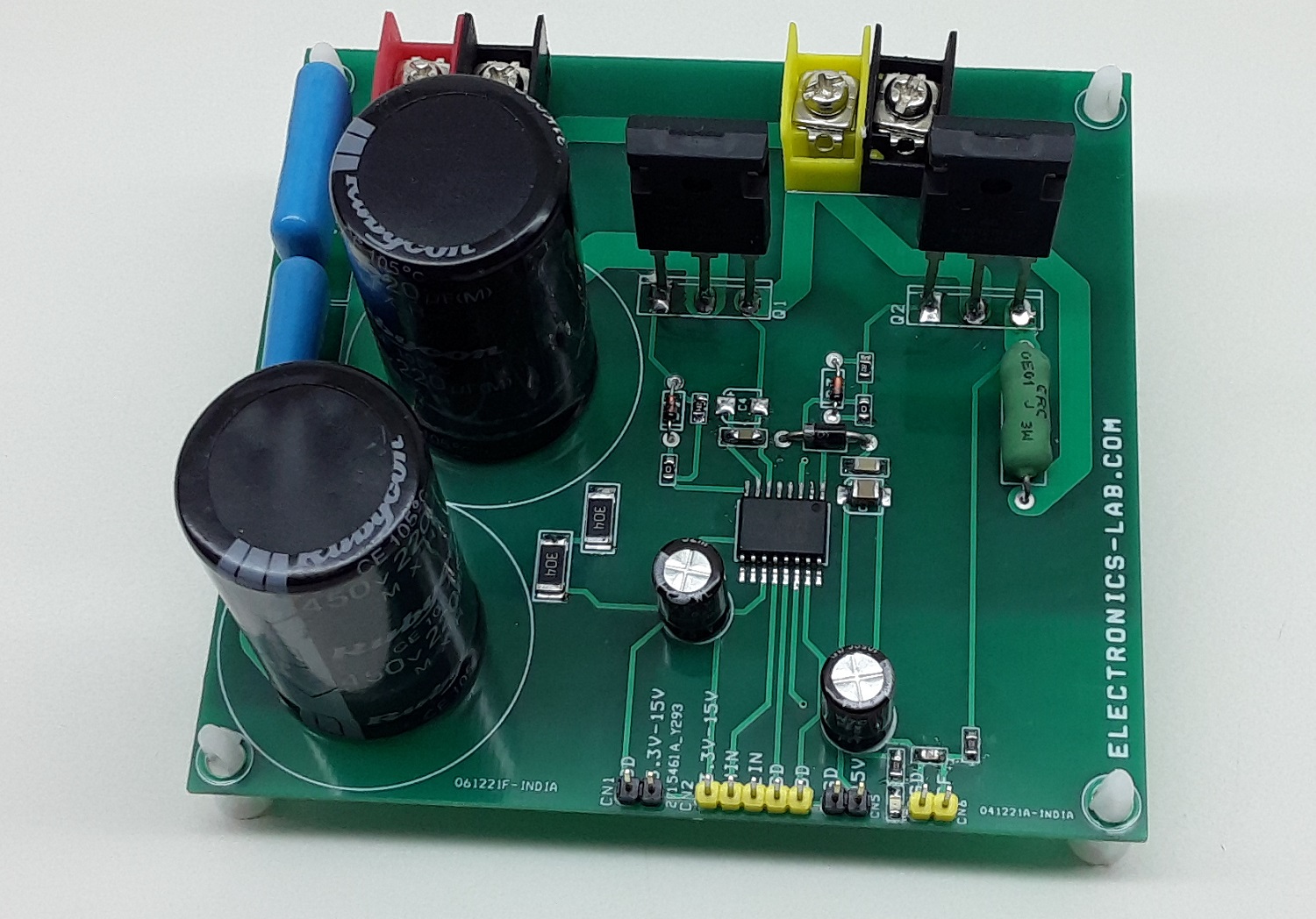

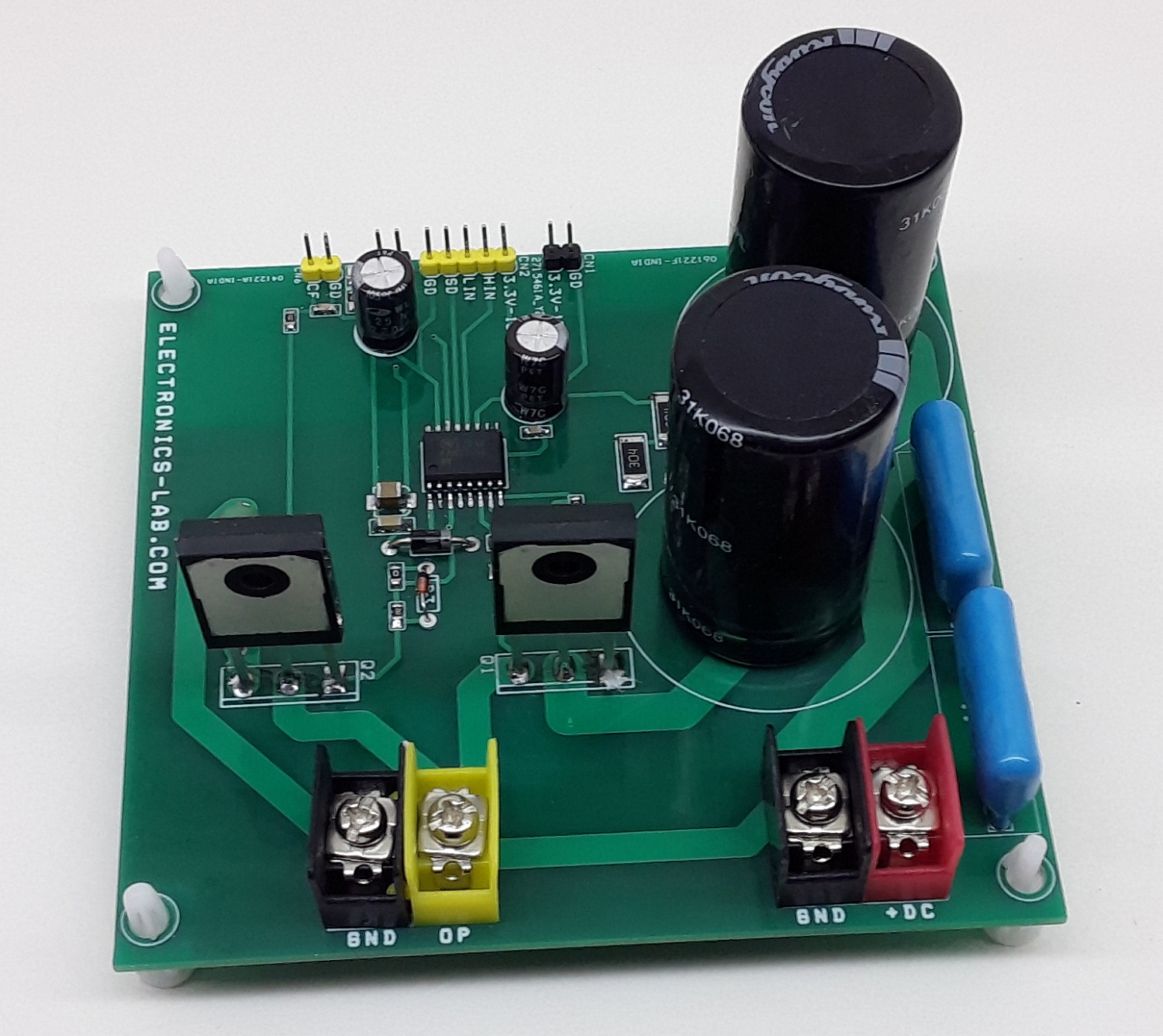

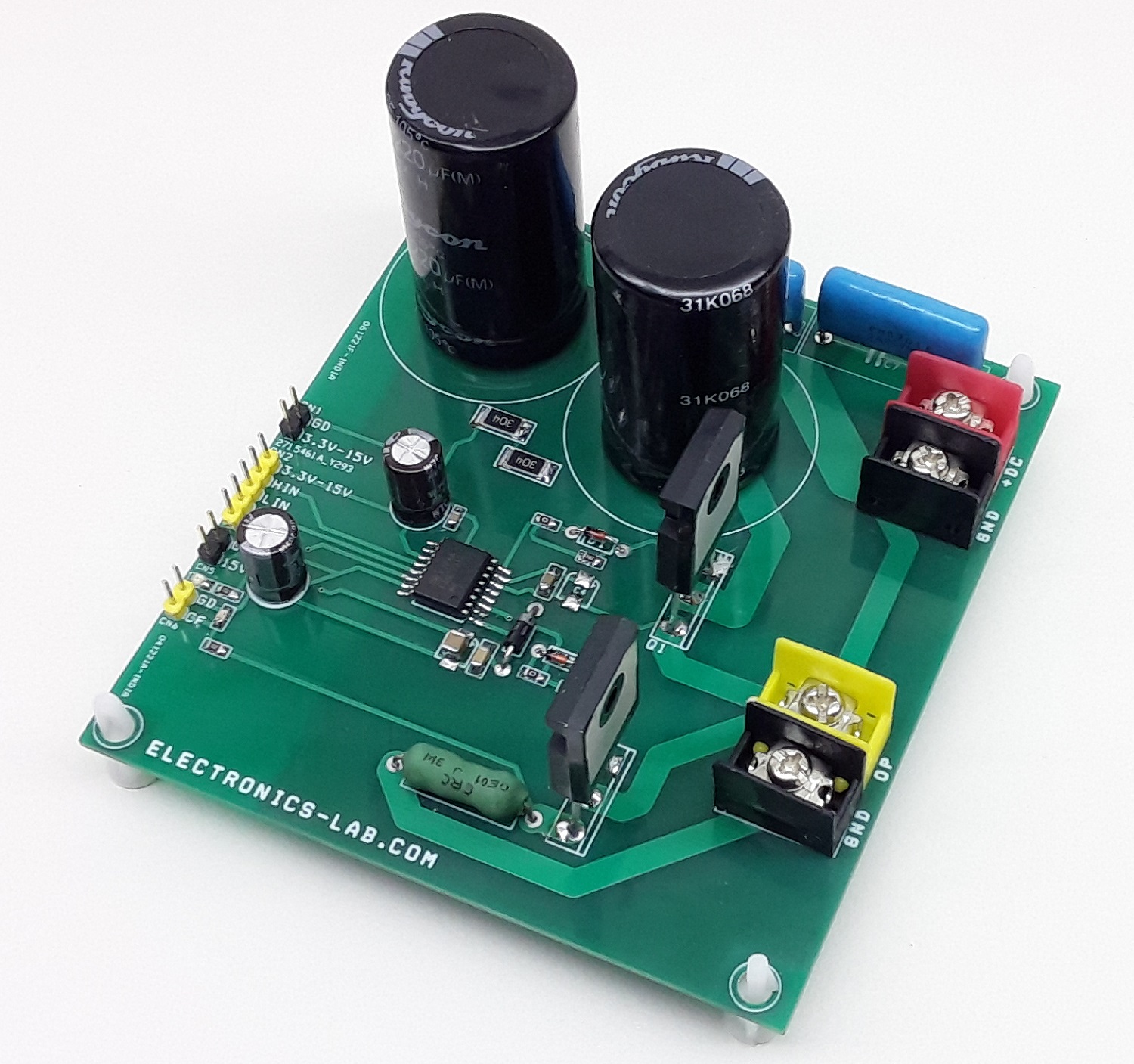

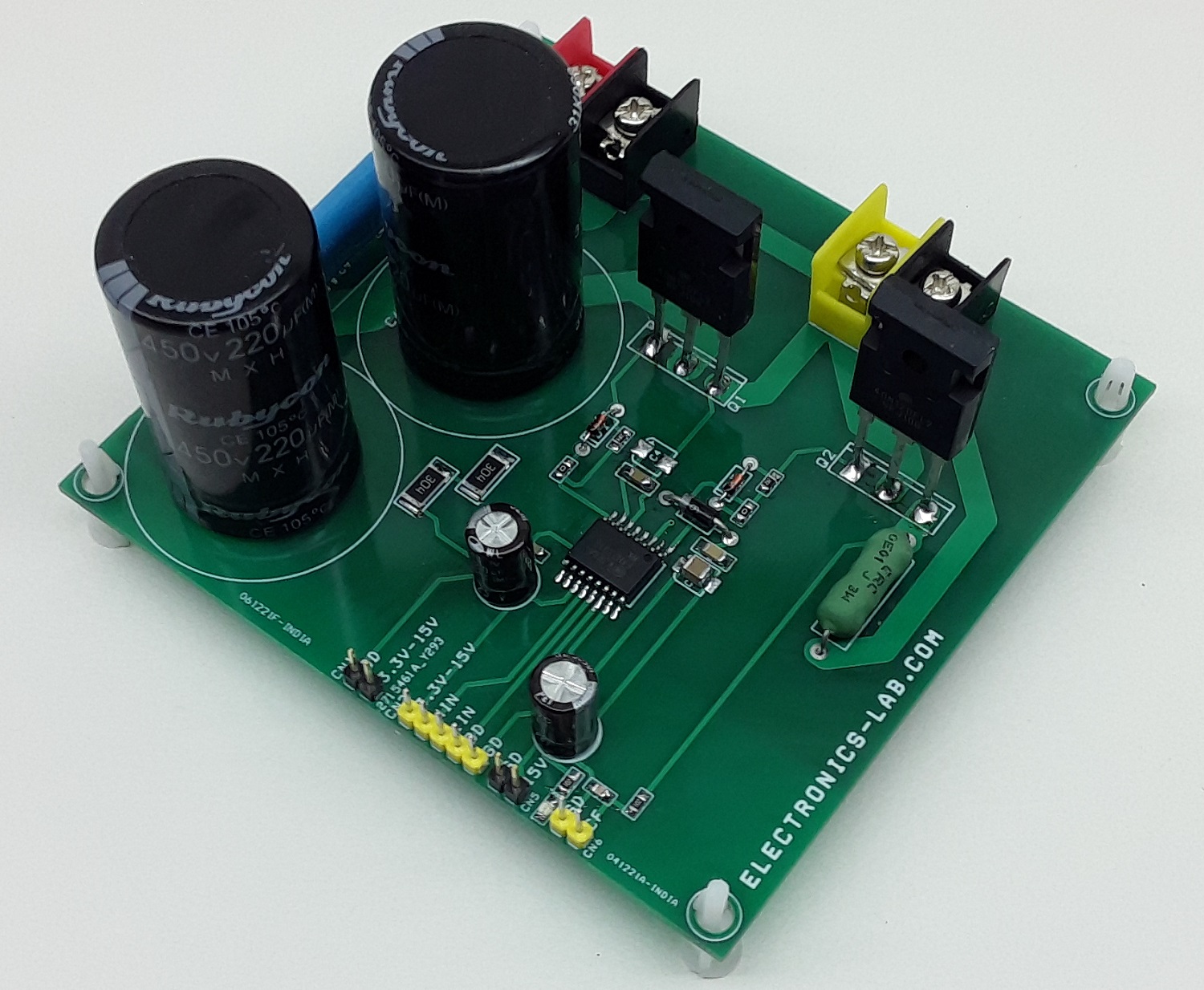

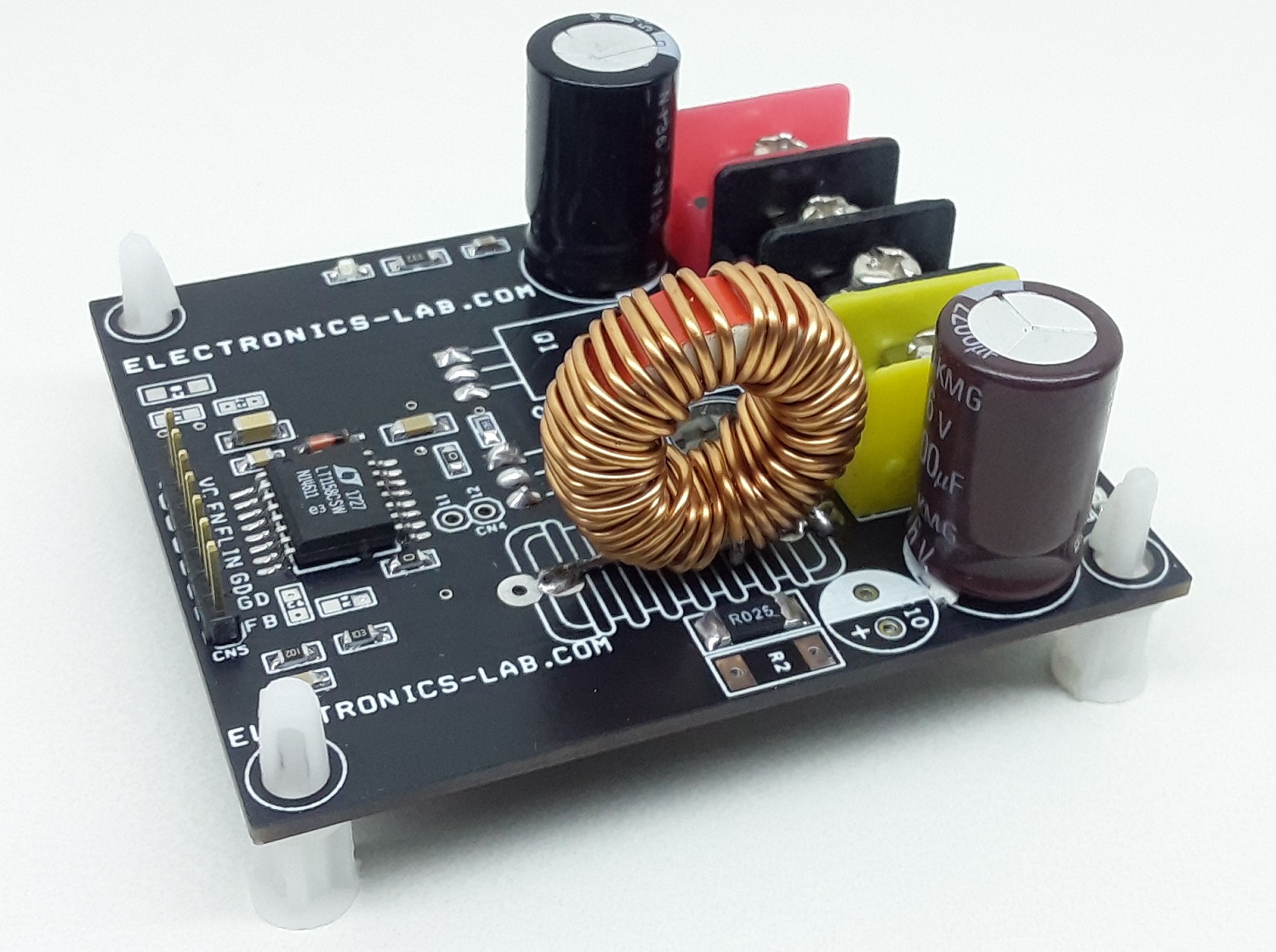

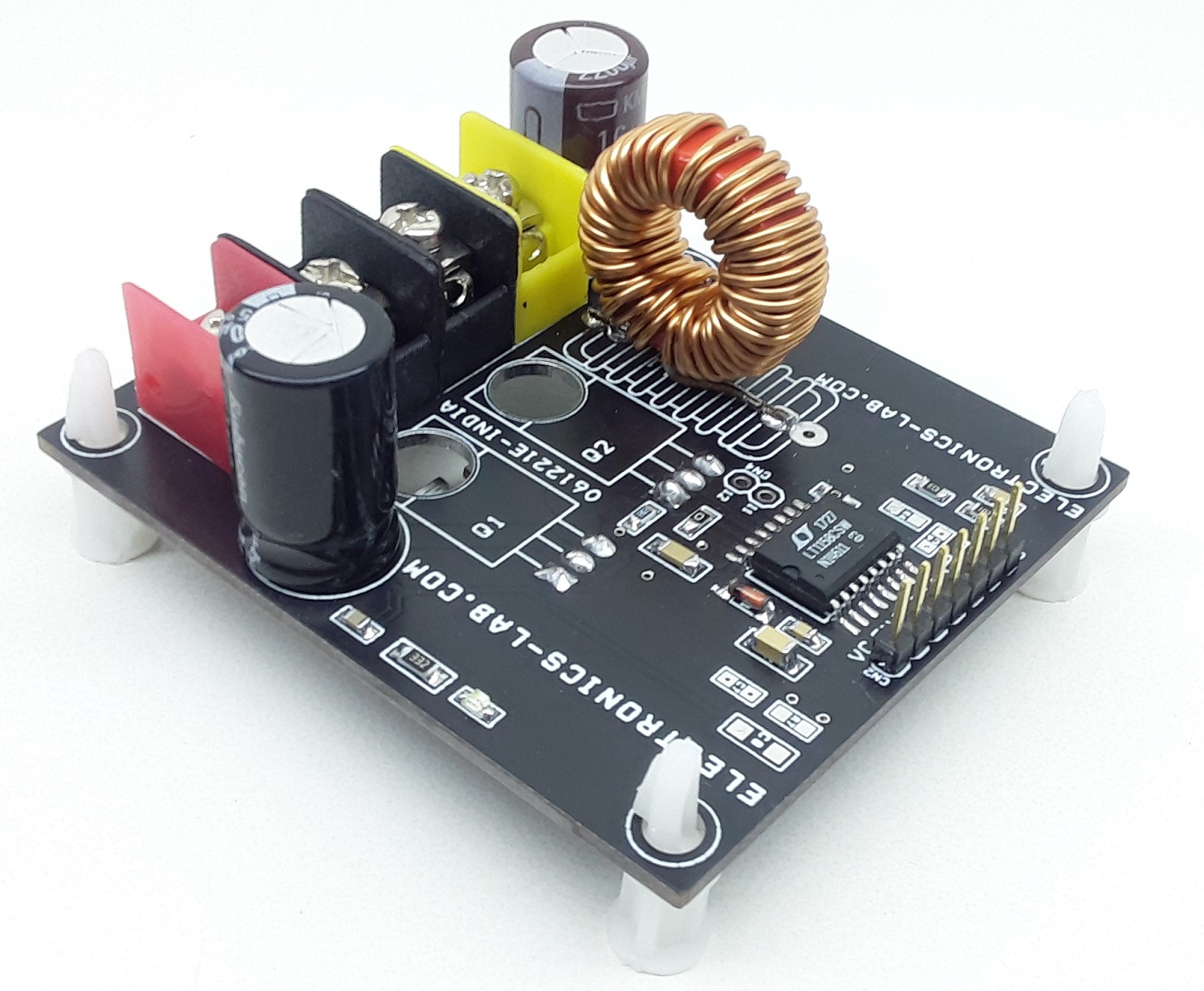

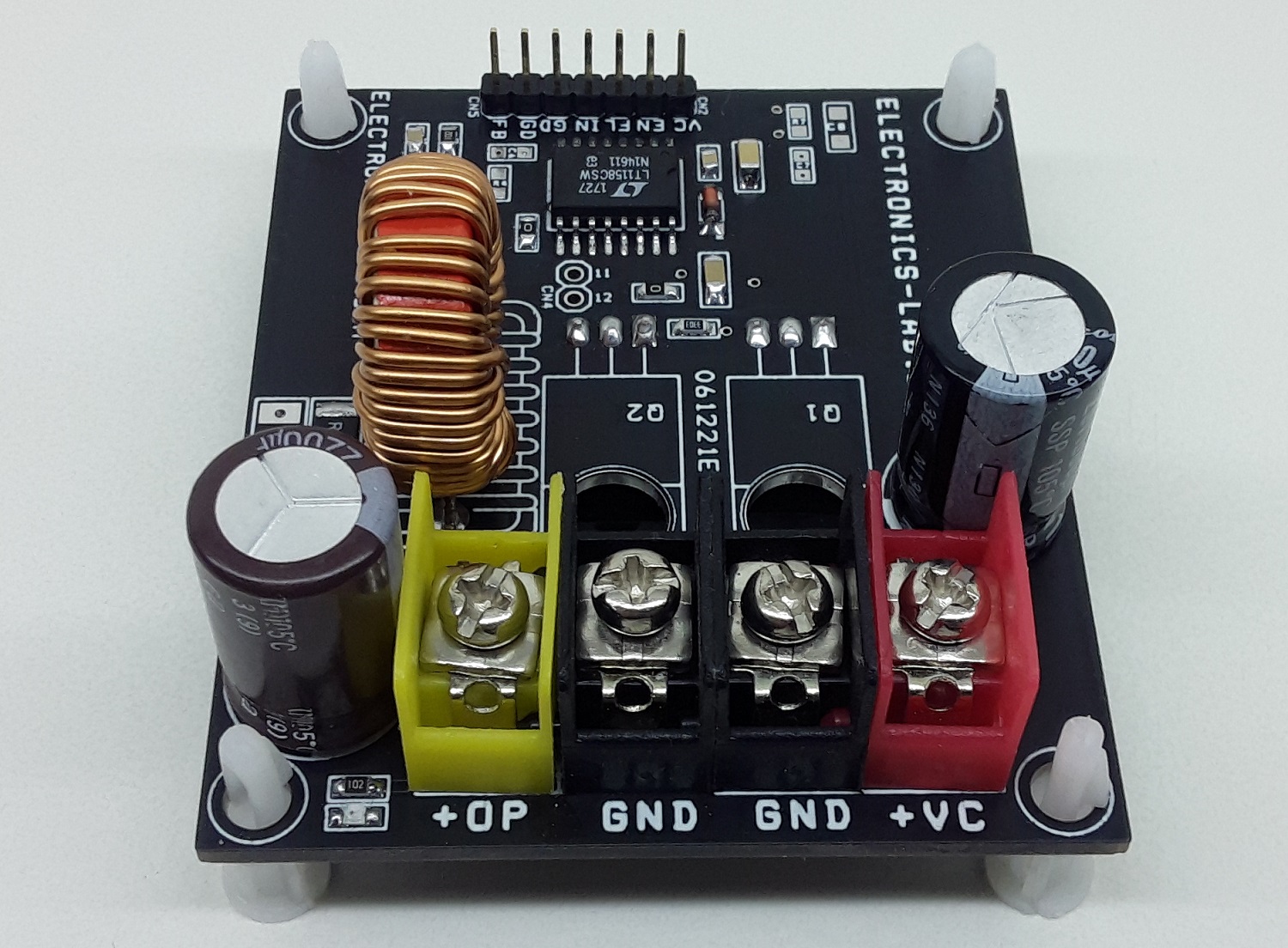

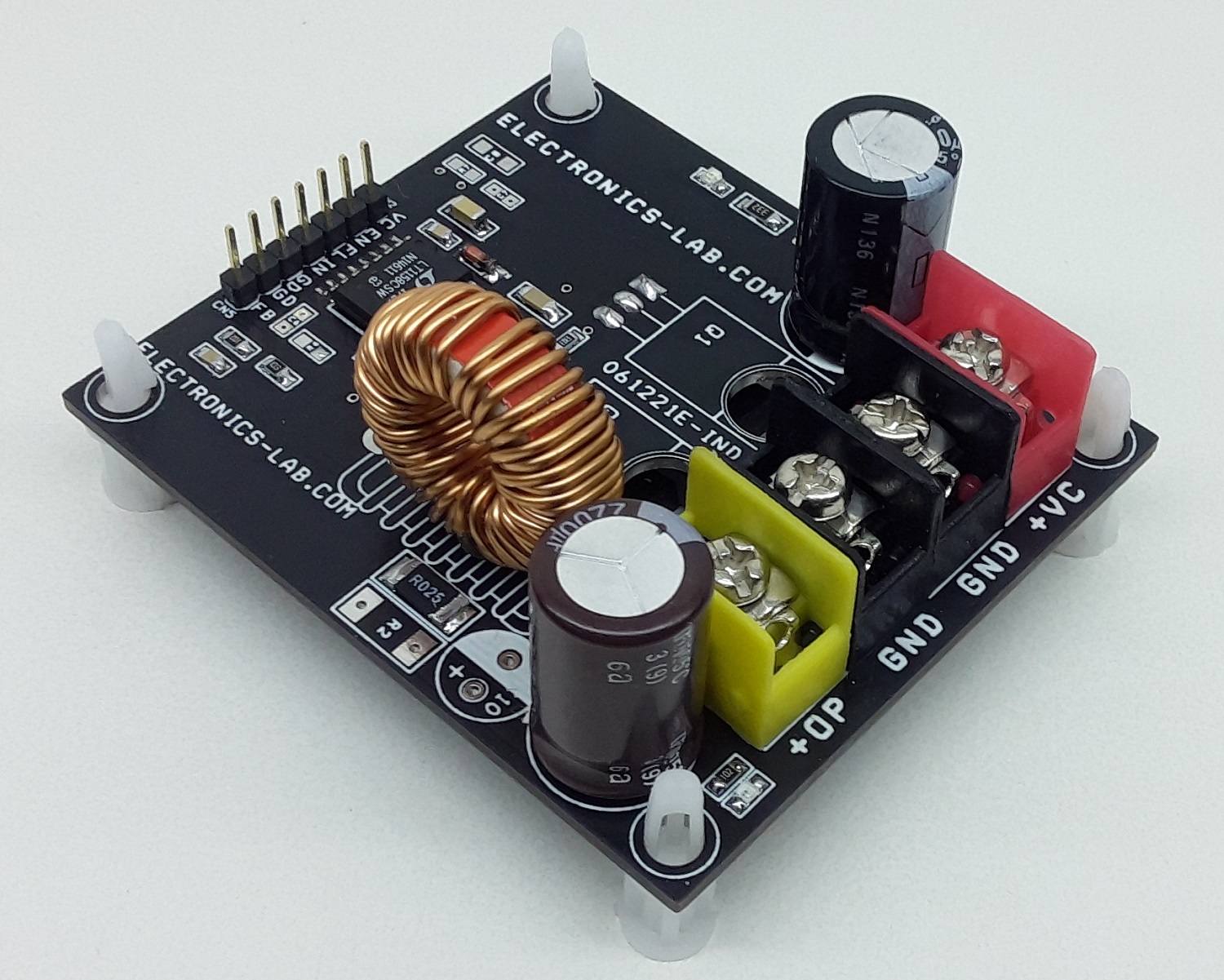

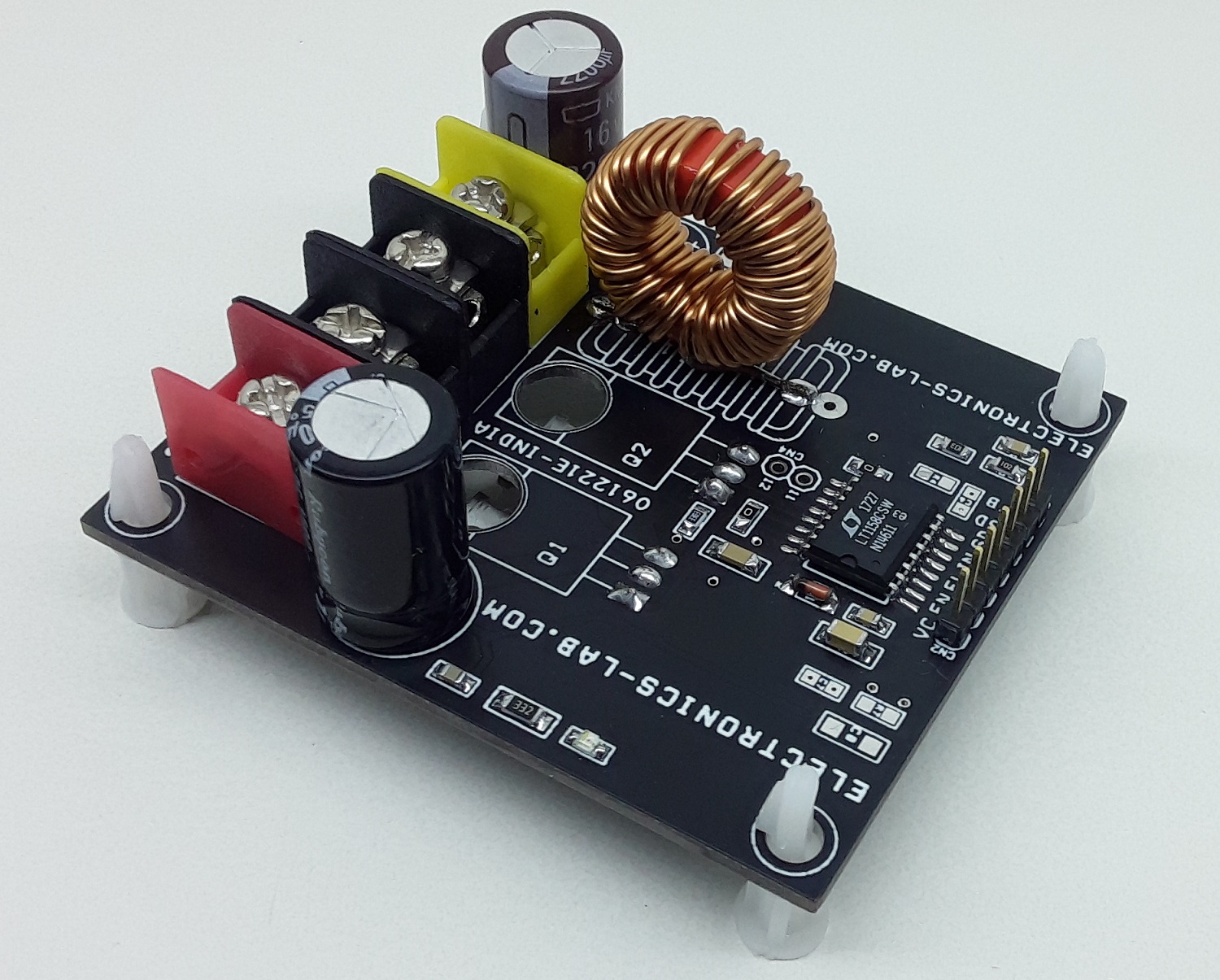

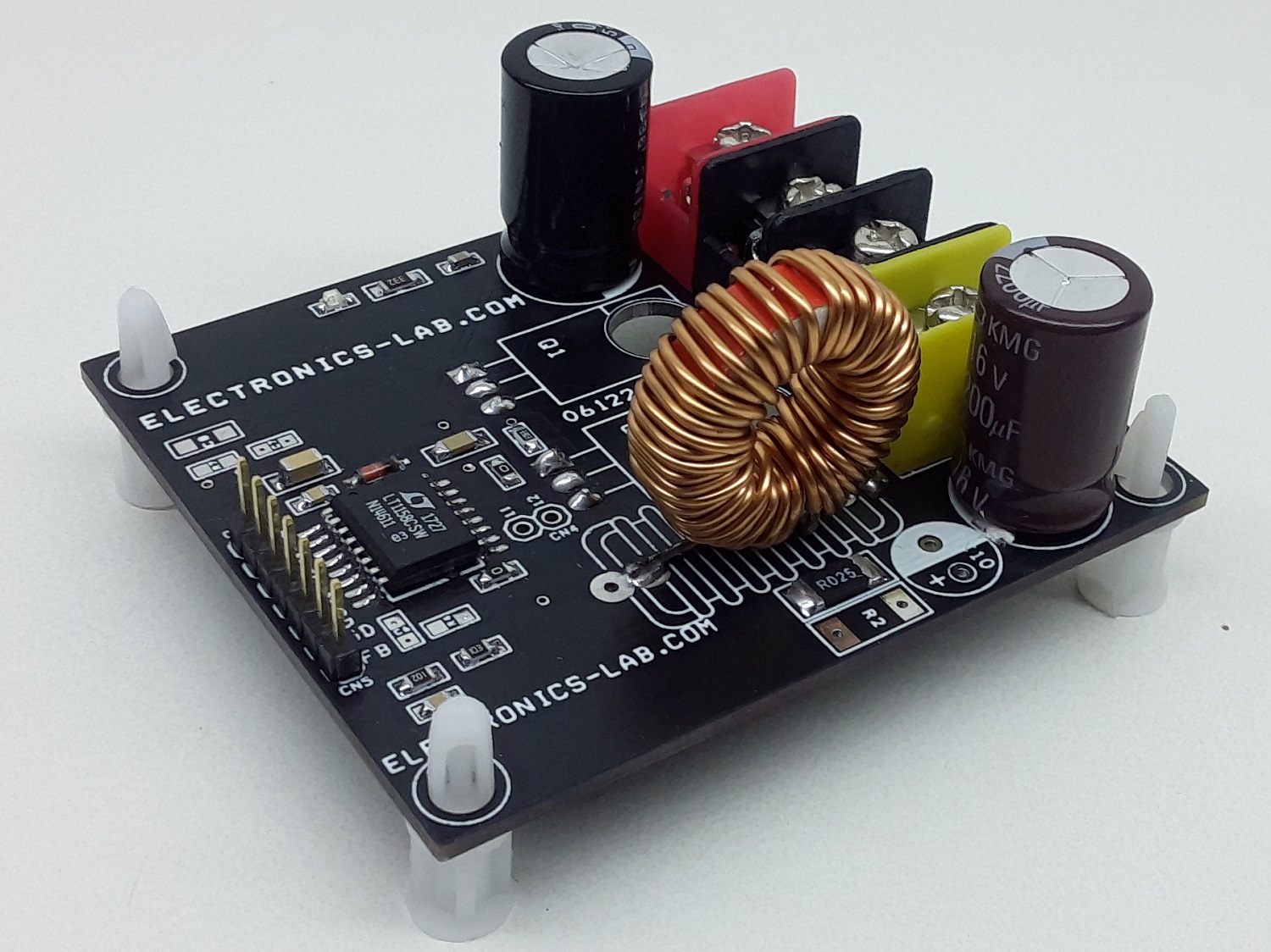

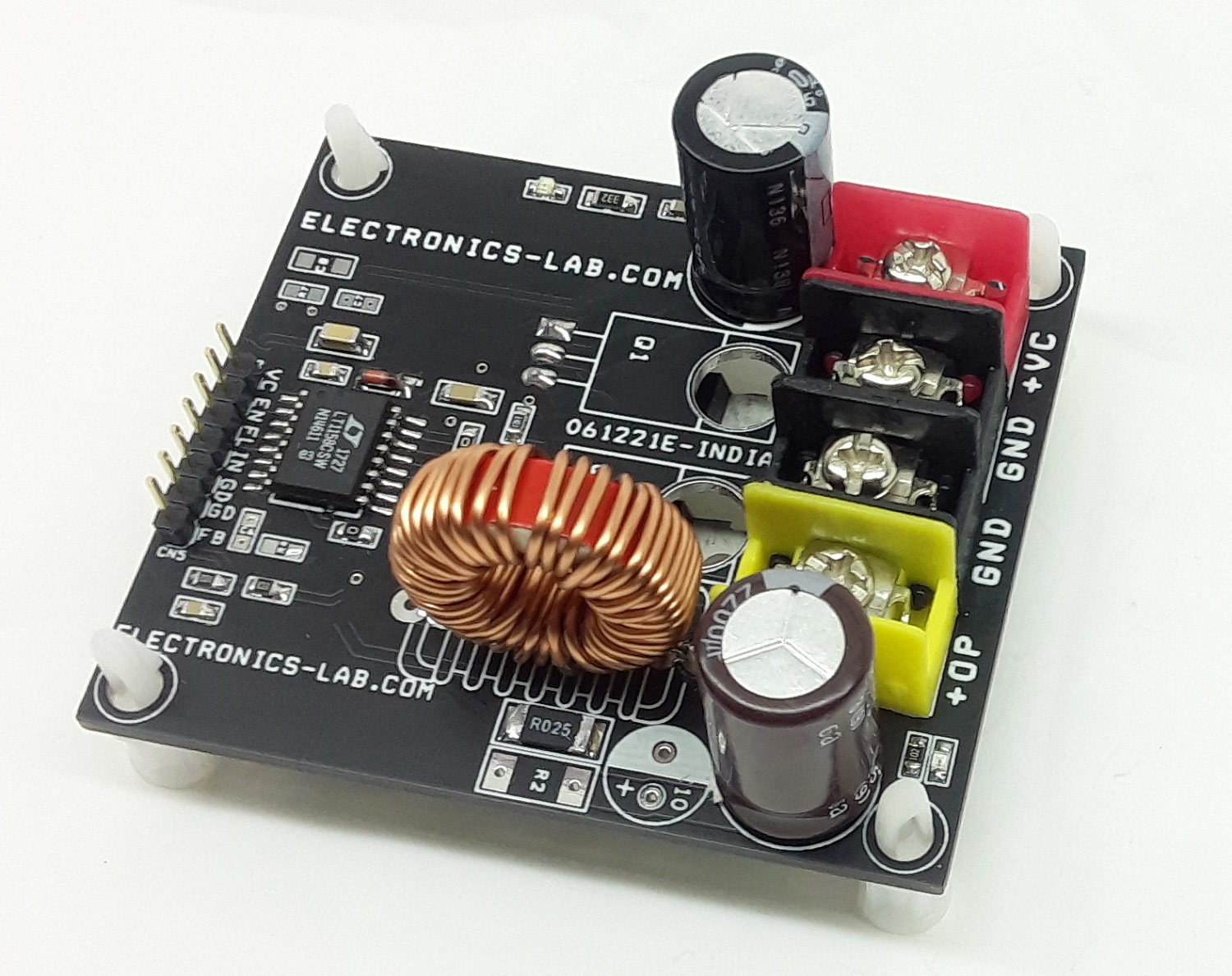

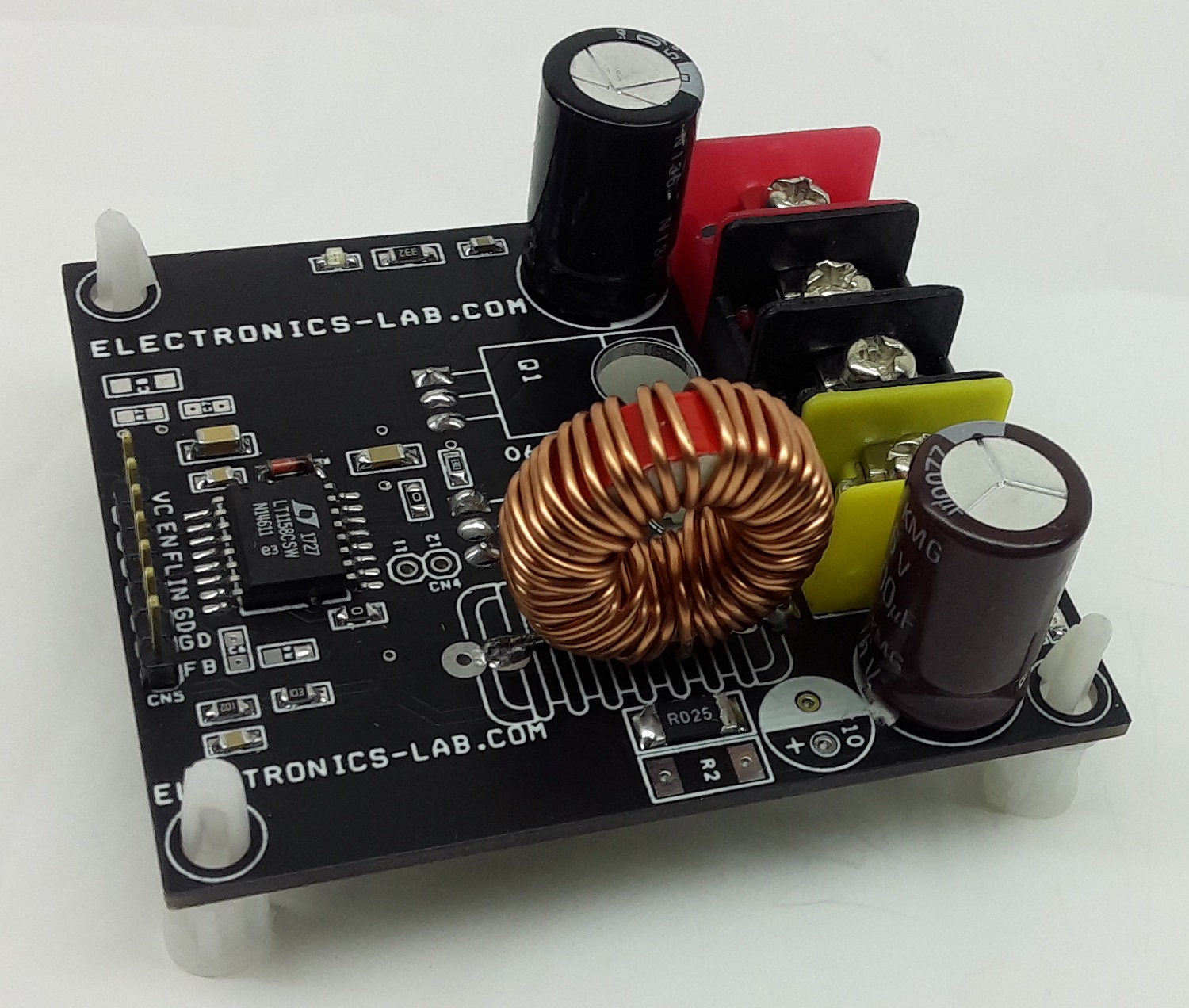

Silanna Semiconductor has further expanded its family of silicon- and GaN-based fast charger reference designs with an all-silicon option that will significantly reduce the time needed to develop high-density 45W applications. Supplied as a fully production-ready solution, the new RD-24 design provides everything needed to rapidly prototype and test a fully functional 45W 1C charger.

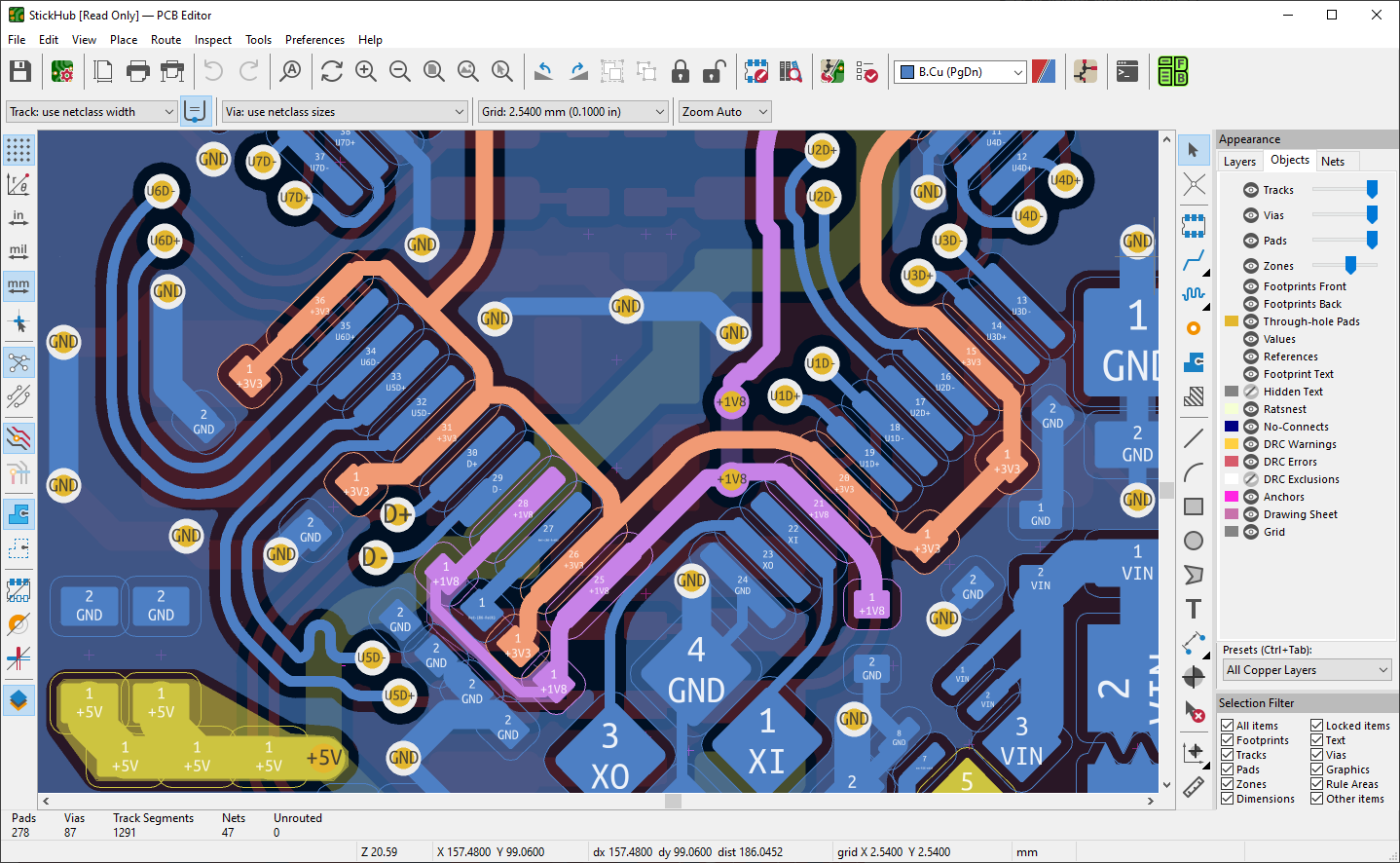

The RD-24 delivers fast charging performance while minimizing overall energy consumption by combining the industry’s best operating efficiency with the lowest ‘vampire’ power consumption. Providing an (uncased) power density of 23.5W/inch3 from a cost-effective single PCB design, the RD-24 operates with a peak efficiency of above 92% and no-load power consumption of below 20mW. Efficiency is flat across the universal input voltage range (90 – 265Vac).

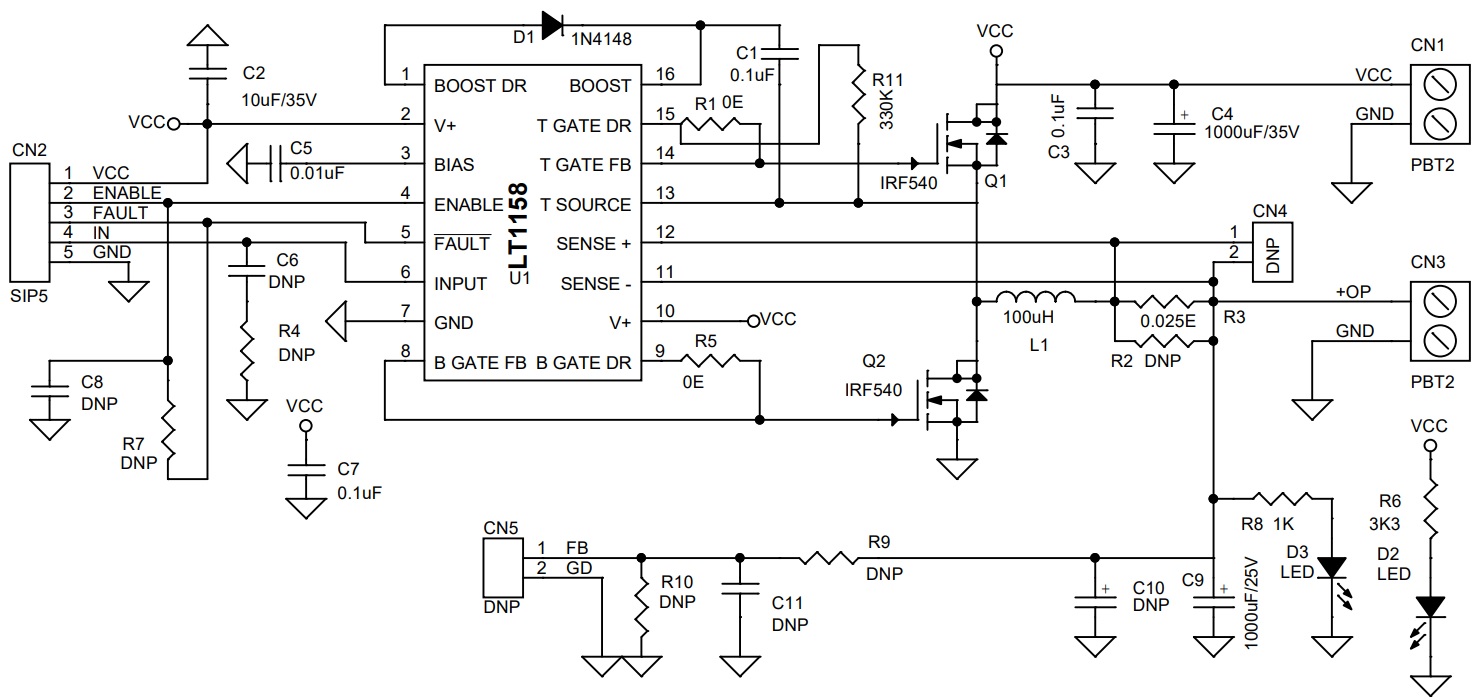

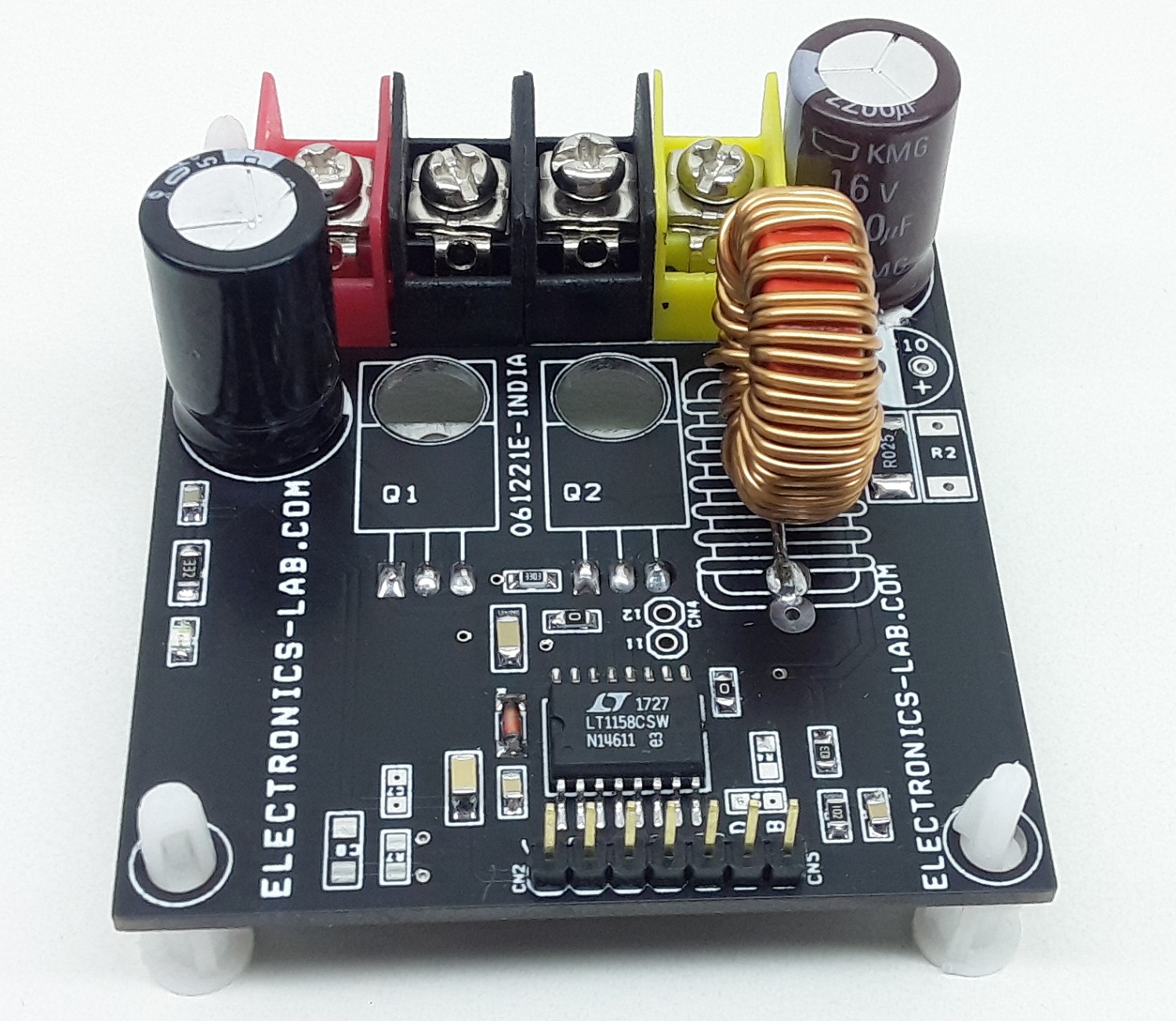

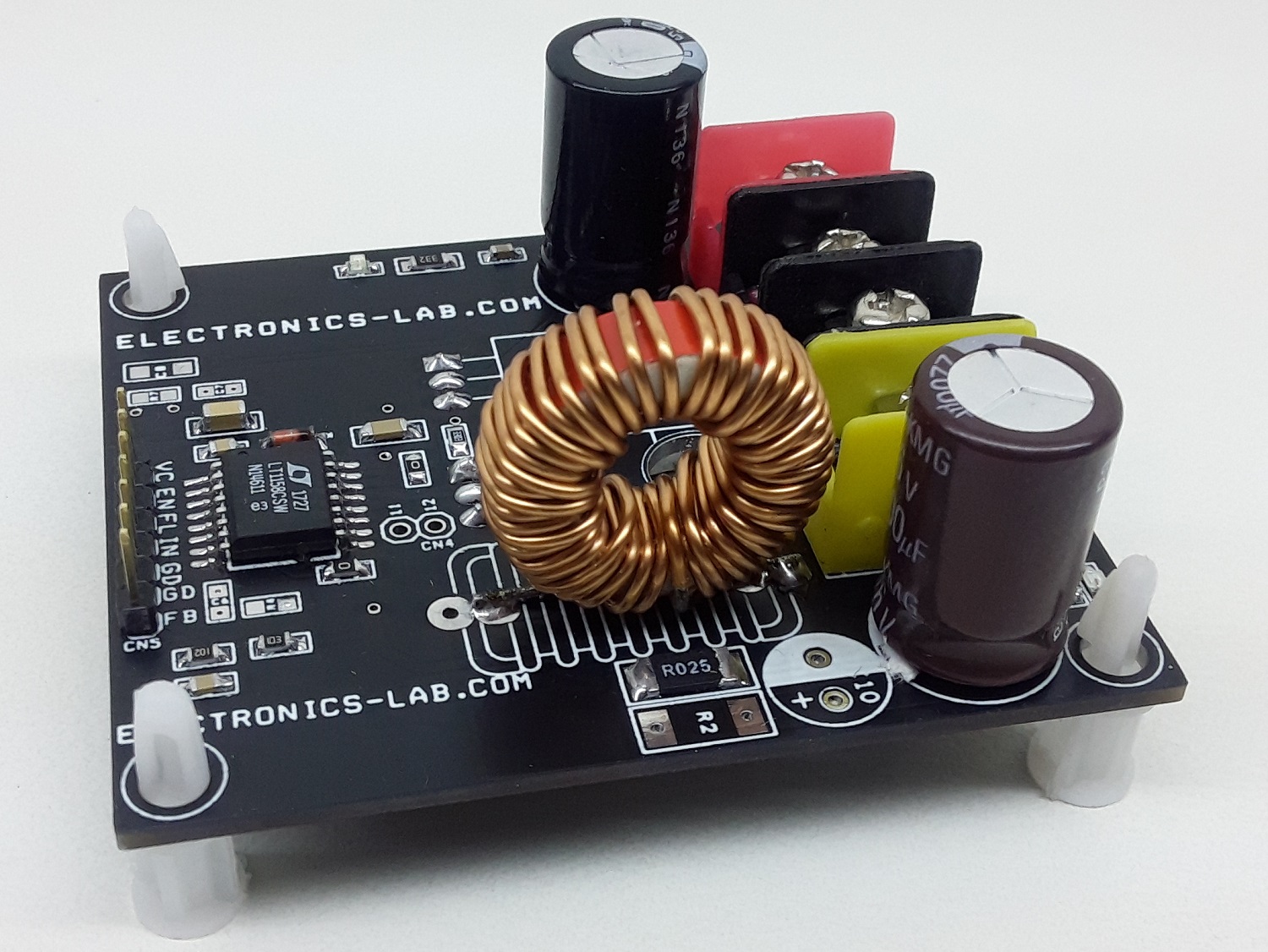

At the heart of the latest reference design is Silanna’s ultra-high-efficiency CO2 Smart Power SZ1131 active clamp flyback (ACF) controller, which is rated for powers up to 65W in universal input designs and above 100W in PFC supported applications. This controller offers a much higher level of integration than has previously been available by incorporating an adaptive digital PWM controller, ultra-high-voltage (UHV) active clamp FET, active clamp gate driver, and startup regulator into a single compact device.

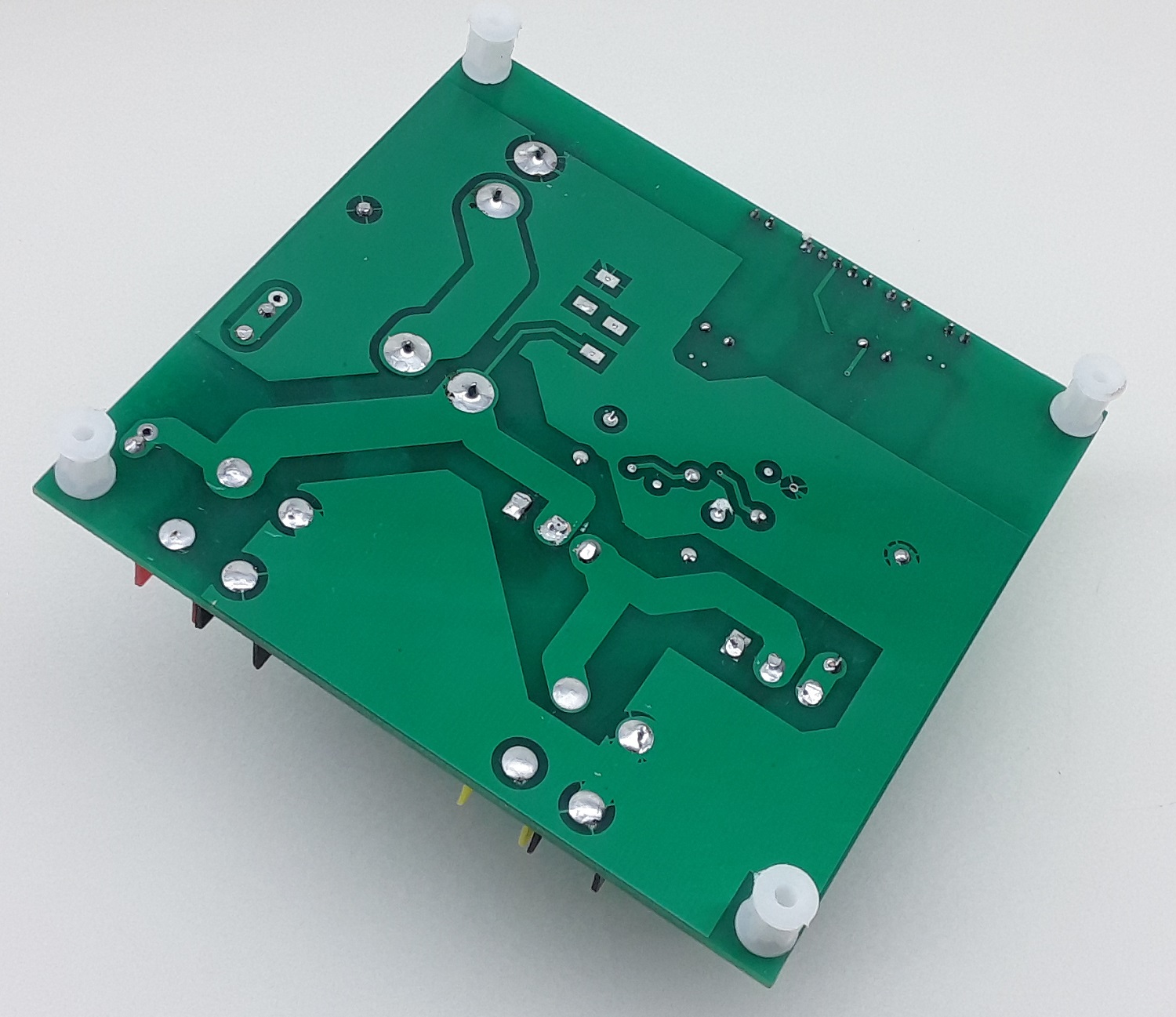

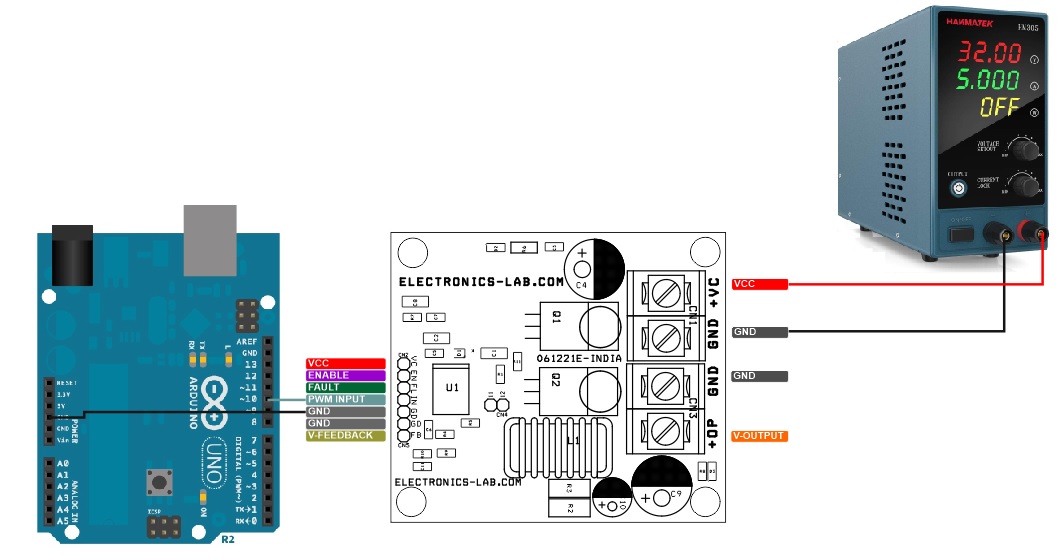

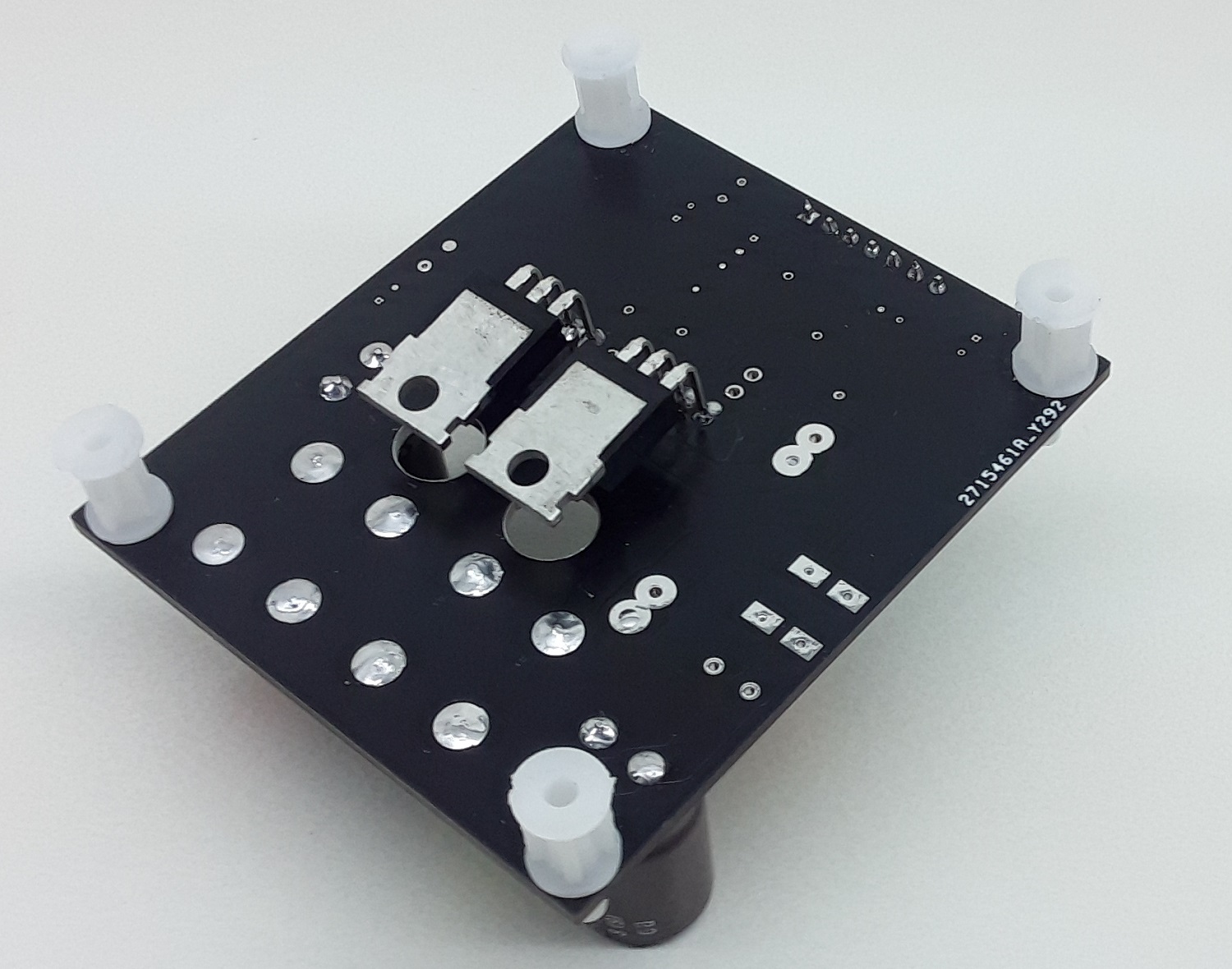

The RD-24 joins a comprehensive family of production-ready reference designs that provide everything needed to develop high-density chargers with low operational and no-load/ standby power consumption and minimum component count, BOM cost, and size. This family includes all-silicon 33W and silicon- and GaN-based 65W USB-PD reference designs. All of these designs exceed conducted and radiated EMI requirements from 3dB to 6dB to eliminate the need for pre-production validation and certification. RD-24 utilizes a single-PCB-based design for the ease of production and assembly, which further reduces the cost for the end customer. Full availability of PCB Gerber and production files reduces the time from prototyping to full production.

RD-24 Key Features

- 45W 1C high-power-density (23.5W/inch3 uncased) reference design

- More than 92% peak efficiency

- Less than 20mW system-level no-load power consumption

- More than 6dB conducted and less than 3dB radiated EMI margins

- Flat efficiency across universal (90 – 265Vac) input voltage and load

- Uses Silanna Semiconductor’s newest fully integrated ACF controller (SZ1131)

- SZ1131 integrates ACF controller with UHV active clamp FET, active clamp driver, and start-up regulator

- Up to 146kHz switching frequency operation

- Ultra-low no-load power consumption

- OptiMode™ cycle-by-cycle adaptive digital control

- Self-tuning valley mode switching (VMS)

- Multi-mode operation (burst mode, QR, VMS)

- OTP, OVP, OCP, OPP, and Output Short Circuit Protections

- CO2 Smart Power by Silanna Semiconductor

The SZ1131 operates at frequencies up to 146kHz and provides the ease-of-design of a simple flyback controller with all the benefits of an ACF design. This includes recycling the leakage inductance energy of the flyback transformer and limiting the primary FET drain voltage spike during turn-off events. Employing Silanna Semiconductor’s OptiModeTM digital control architecture, the SZ1131 adjusts the device’s mode of operation on a cycle-by-cycle basis to maintain high efficiency, low EMI, fast dynamic load regulation, and other key power supply parameters in response to varying line voltage and load conditions.

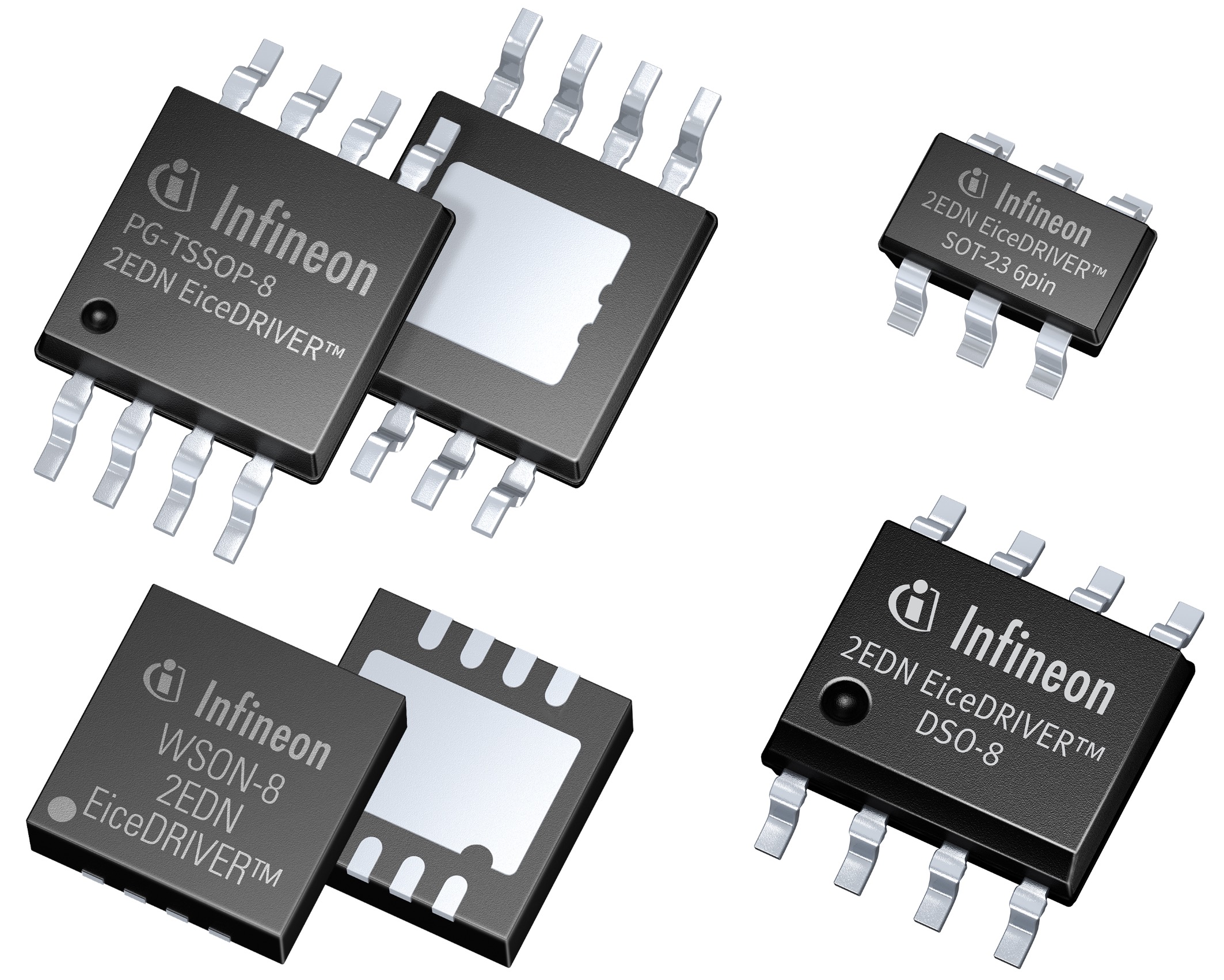

Supplied in a 16-pin SOIC package, the SZ1131 offers protection against over-temperature, over-voltage, over-current, over-power, output short circuit, and transformer core saturation faults without the need for additional external components.

RD-24 Key Features include: 45W 1C high-power-density (23.5W/inch3 uncased) reference design; More than 92% peak efficiency; Less than 20mW system-level no-load power consumption; More than 6dB conducted and less than 3dB radiated EMI margins; Flat efficiency across universal (90 – 265Vac) input voltage and load; Uses Silanna Semiconductor’s newest fully integrated ACF controller (SZ1131); SZ1131 integrates ACF controller with UHV active clamp FET, active clamp driver, and start-up regulator; Up to 146kHz switching frequency operation; Ultra-low no-load power consumption; OptiMode cycle-by-cycle adaptive digital control; Self-tuning valley mode switching (VMS); Multi-mode operation (burst mode, QR, VMS); OTP, OVP, OCP, OPP, and Output Short Circuit Protections; CO2 Smart Power by Silanna Semiconductor;