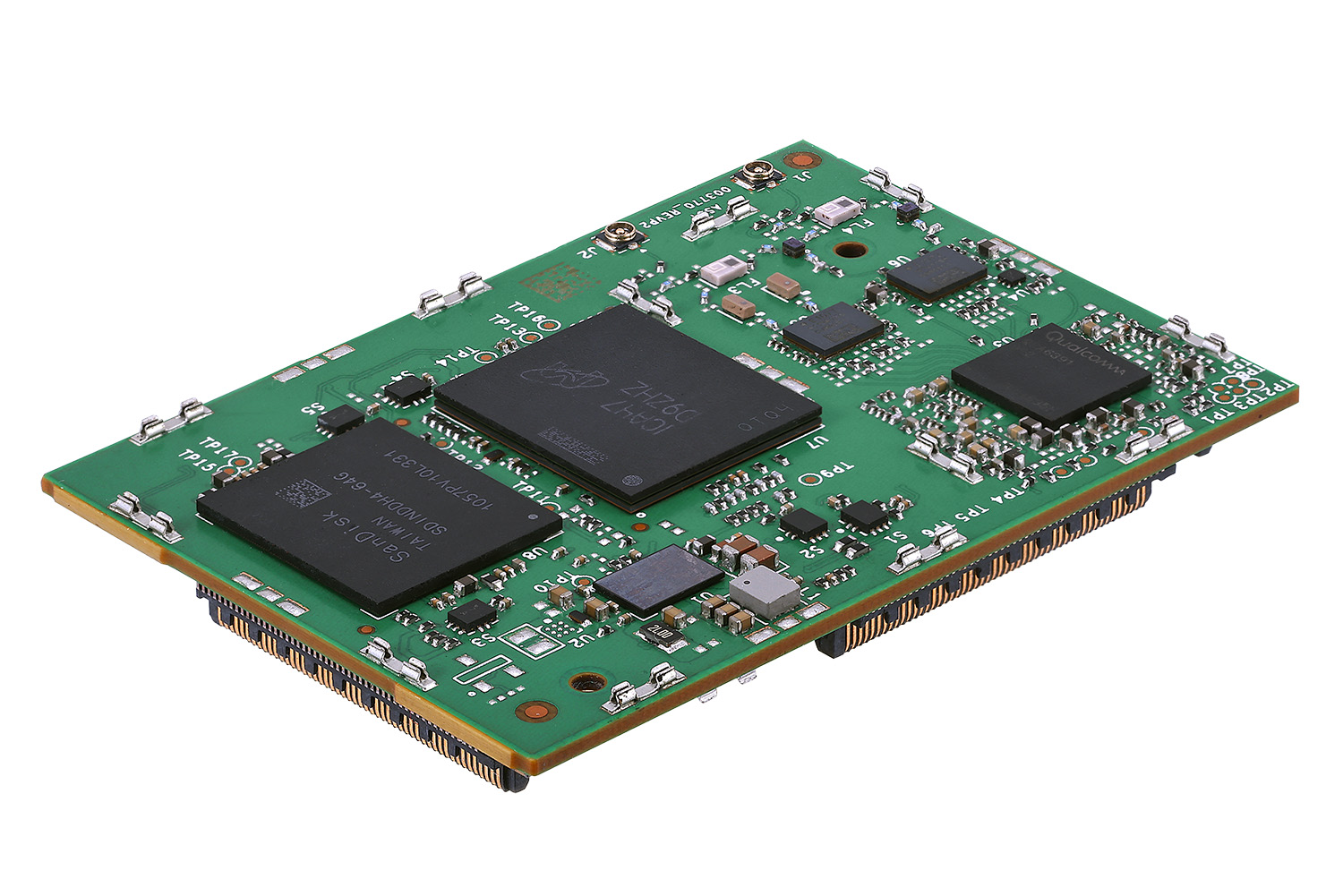

SMART Wireless Computing, Inc., an SGH company and leading provider of edge computing embedded solutions, today announced the Inforce 68A1 system-on-module (SoM), a powerful new tool based on one of the latest and most advanced IoT solutions from Qualcomm Technologies, Inc., the Qualcomm® QCS8250 system-on-chip (SoC), which is designed to provide high performance for compute-intensive network edge Internet of Things (IoT) camera applications. The Inforce 68A1 SoM combines support for multiple high-resolution 8K or 4K cameras with complex artificial intelligence (AI) inferencing at the edge to enable smart camera systems, high-performance conferencing/collaboration devices, connected healthcare, and intelligent retail devices.

The Inforce 68A1 SoM provides exceptionally high-resolution video capabilities, including processing 4K60 Ultra HD content for multiple cameras and displays concurrently, plus high bandwidth connectivity via 802.11ax DBS Wi-Fi 6E and Bluetooth 5 for connected camera networks. The module makes use of Qualcomm Technologies’ high-performance Qualcomm® Hexagon™ DSP and Qualcomm® AI Engine to efficiently run heterogeneous deep learning workloads and neural networks for high-performance, on-device AI inferencing used in video analytics and to improve the user experience.

Video Conferencing Use Case

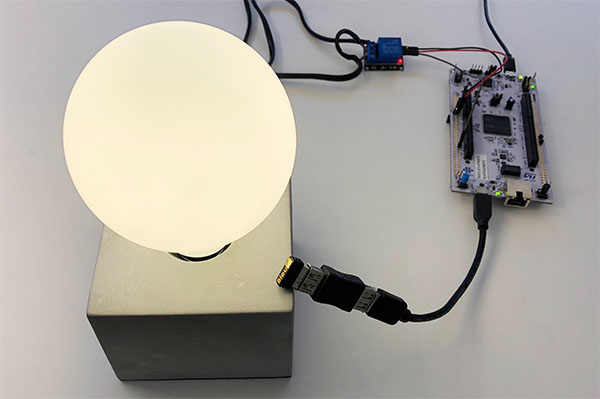

Never before has reliable video conferencing been more in demand, with companies across the globe embracing AI technology to simplify audio-visual collaboration as remote working becomes more widely adopted. By integrating the Inforce 68A1 SoM into enterprise video conferencing solutions, businesses can deliver content, connect and interact effortlessly, from anywhere, for a flawless video experience.

Medical Use Case

Similarly, applying computer vision AI to medical fields, such as portable ultrasound machines, can help provide remote anatomical identification with fewer clicks and increased accuracy. This anatomical identification also helps automate measurements, make them more reproducible, and can give medical professionals tools to improve patient care, and bolster the resources of hospitals that lack adequate medical imaging resources.

Retail Use Case

As retailers look to keep up with changing landscapes, the introduction of AI video content analysis solutions presents an entirely new level of data processing which leads to a deeper understanding of consumer attitudes, preferences, and buying habits. By integrating the Inforce 68A1 SoM into retail camera systems and self-checkout technology, retailers can improve merchandising and enhance customer behavior and engagement while providing a seamless, low-contact shopping experience.

“With vast progress being made in AI and machine learning, applications that previously involved manual intervention can now be automated or enhanced to solve some of the most common challenges in our day-to-day lives,” said Todd Wynia, vice president, product marketing at SMART Wireless Computing. “Our application-ready embedded platforms are at the core of this, providing multiple options for global IoT connectivity, multimedia capabilities, and powerful edge computing power, revolutionizing the way we communicate, shop and approach healthcare, among many other possible applications.”

“The Qualcomm QCS8250 SoC targets high performance, on-device camera applications in retail video analytics, connected healthcare, digital signage and enterprise video collaboration,” said Siddhartha Franco, director, business development, Qualcomm Technologies, Inc. “This device is optimized for maximum performance while balancing power efficiency with support for Wi-Fi 6 and 5G connectivity. The SMART Wireless Inforce 68A1 SoM brings technology at the connected intelligent edge to a broader ecosystem of developers, helping reduce the time and risks involved with integrating premium tier AI performance into their edge camera solutions.”

This latest module includes an Android 10 board support package with the Qualcomm Technologies’ software development kits, including Hexagon SDK and Qualcomm® Neural Processing Engine SDK, enabled.

Technical Specifications and Application Benefits

- The Qualcomm QCS8250 SoC at the heart of the Inforce 68A1 SoM integrates:

- The Qualcomm® Kryo™ 585 CPU is one of the company’s most advanced processors for IoT applications that provides excellent performance and multi-tasking.

- The Qualcomm® Adreno™ 650 GPU provides a highly efficient graphics core, delivering twice the performance of the previous generation platform, and 60 percent greater power efficiency.

- The Hexagon™ 690 DSP runs power efficient machine learning with quad-threaded Scalar performance and twice the Vector eXtensions performance

- A dedicated computer vision hardware block and new Hexagon Tensor Accelerator delivering 15 TOPS of AI performance

- The Qualcomm® Spectra™ 480 ISP enables image capture at 64MP@30fps ZSL with no shutter lag and quick autofocus.

- The Adreno DPU995 Display Engine enables dual concurrent display content at HEVC 10bit and VP9 decode.

- Wired and wireless connectivity options include Wi-Fi 6, 5G, Bluetooth 5.1 RF front-end technologies and dual USB 3.1.

- A secure processing unit enables secure boot, DRM and content protection creating a secure environment for the camera system.

- The Inforce 68A1 SoM leverages PMIC regulators for large power requirements and on-board power management.

- On-board memory and storage includes 8GB DDR5 RAM and 64GB Universal Flash Storage (UFS) for fast multitasking.

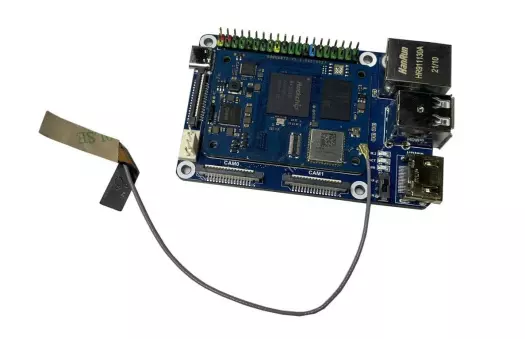

- Designed to fit into and power ultra-thin applications, the small form factor SoM measures just 35 mm x 53 mm (7.5 mm profile).

- Electromagnetic interference (EMI) shielding provides radio frequency noise protection, while also improving heat dissipation to improve performance.

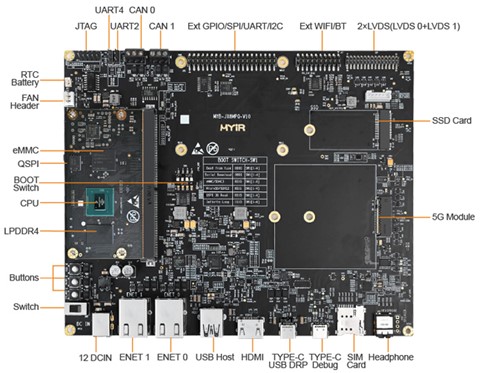

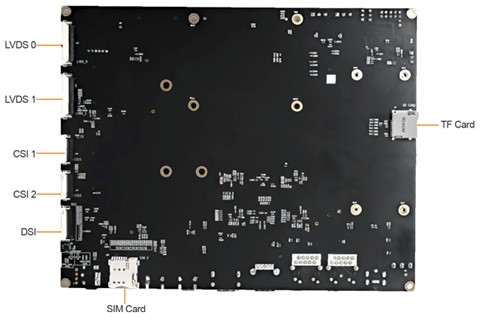

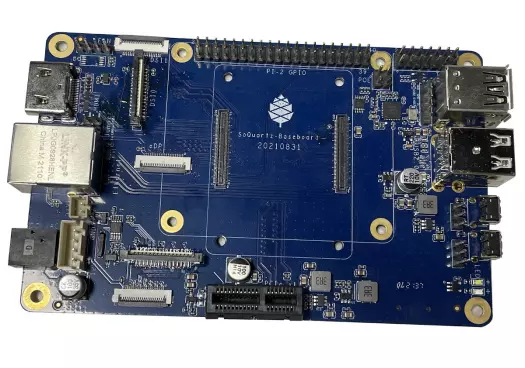

- A development kit based on this SoM offers functionality to help developers create and optimize their products quickly, cost effectively and with lower risk.

Starting in December, customer samples will be available to order at www.smartwirelesscompute.com priced at $399 for the SoM and $749 for the development kit, which includes a SoM, evaluation carrier board with IO, and a starter kit that includes a power adapter and cable.