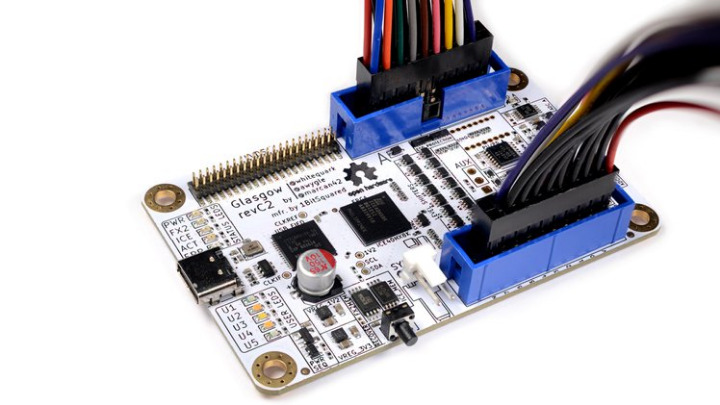

1BitSquared has launched on Crowdsupply it’s Glasgow Interface Explorer. The board is said to be designed for hardware designers, reverse engineers, digital archivists, electronics hobbyists, and anyone else who wants to communicate with a wide selection of digital devices with minimum hassle. The board is designed to be attached to the majority of devices without additional active or passive components, and it enables extensive protection from unexpected conditions and operator error. There have been other boards for hardware hackers and engineers recently, like the Ollieand Tigard USB debug boards. Glasgow is the latest of these sets of boards. The Glasgow hardware offers support for many digital interfaces thanks to its reconfigurable logic. Instead of offering just a small selection of standard hardware supported interfaces, it uses an FPGA to adapt — on the fly — to the task at hand without compromising performance or reliability, even for unusual, custom, or obsolete interfaces.

The Glasgow software features a set of building blocks designed to eliminate system complexity. Each of these protocols is placed into a self-contained applet that can be used directly from the command line or integrated into a more complex system. The Glasgow software is easy to use, it does not require any programming knowledge, although you can do much more with it if you know a bit of Python. Glasgow can function as a USB-to-serial adapter, and unlike traditional serial adapters, it can auto-detect the target voltage and “mirror” it. It goes further by auto-detecting the baud rate of the target and follow it on the fly. Glasgow can also directly interface to inverted signal UART interfaces, which would conventionally require additional debugging components, like buffer transistors. Glasgow also features built-in support for InfluxDB. This enables any applet that reads out sensors to directly log the data and you can visualize them in Grafanawith with very minimal effort.

Talking about the versatility of the Glasgow, they say:

“Today there are a lot of different LED display technologies available. Like “intelligent” RGB LEDs with built in PWM controllers, for example WS2812 or APA102. There are LED matrix display panels with myriad of shift register based interfaces like HUB75, HUB75e, HUB8, HUB12 and many more. All of them use fairly nonstandard protocols. From timing-driven one-wire interfaces, through fairly normal SPI interfaces to multichannel parallel shift register interfaces. Typical protocol adapters only provide a specific subset of hardware supported interfaces. Everything beyond that has to be implemented with so called bit-banging. Bit-banging means that the processor or the PC has to control I/O step from software, in some cases even through USB. This is cumbersome if not impossible due to the timing constraint and USB speed. In the case of Glasgow, that can be easily reconfigured. It is possible to experiment and prototype with these devices quickly and with minimal hassle. Just a few lines of nMigen and Python and you are ready to go.”

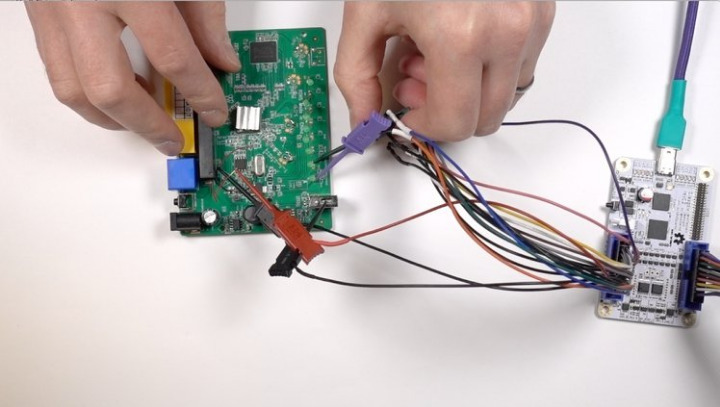

The company also designed a beautiful CNC-milled aluminum case to keep the Glasgow safe from damage. However, it’s available as an option. You can find more information about Glasgow Interface Explorer on Crowd Supply, and you can pledge $139 to get the latest RevC revision of the board as well as a full set of flywire, sync, and USB-C cables. Available also is an optional CNC-milled and anodized aluminum case that selling for $50. Shipping will be free to the US, and the shipping fee will depend on weight and destination for other countries. Shipping is scheduled for May 31, 2021.