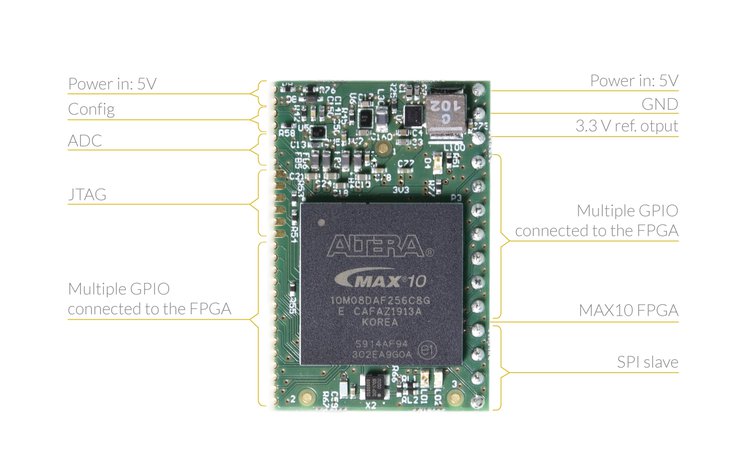

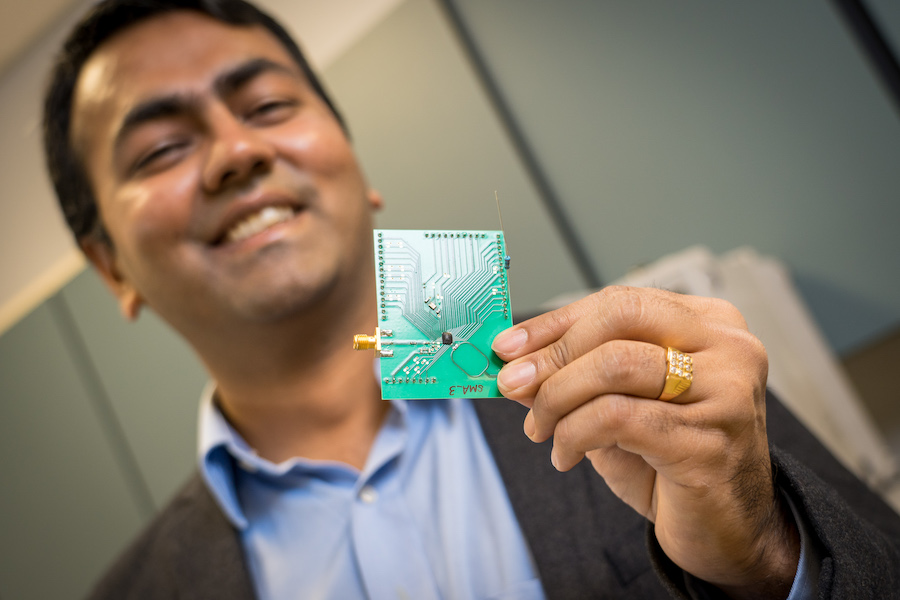

Electrical engineers from the University of California, San Diego recently designed a new portable chip that consumes 5000 less power than the Wi-Fi radios that we have today.

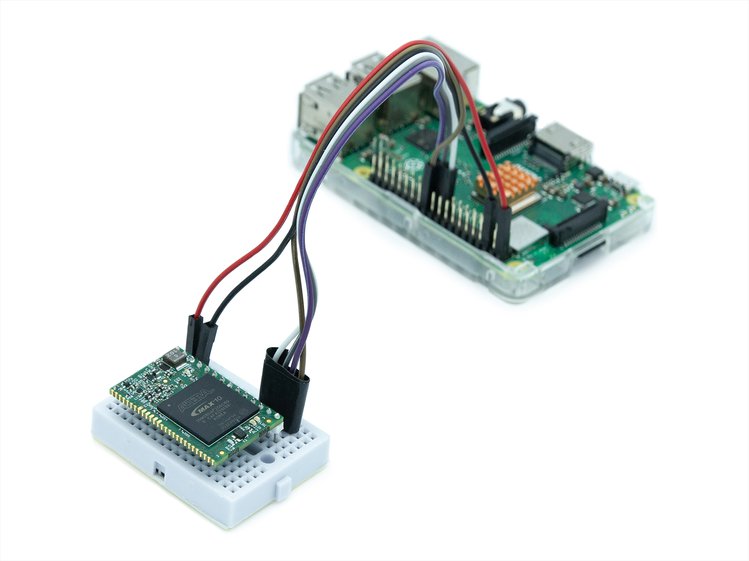

The new chip, which is smaller in size compared with a grain of rice, is said to be ideal for IoT devices, smart home setups, and wearables. With just 28 microwatts of power, the tiny chip can allow devices to connect with existing Wi-Fi networks and transmit data at a rate of two megabits per second within a range of 21 meters.

Smart devices, mobile phones and even small cameras or various sensors to this chip, it can directly send data from these devices to a Wi-Fi access point near you. You don’t need to buy anything else and it could last for years on a single coin cell battery,” explains Dinesh Bharadia who is one of Professors of UC San Diego electrical and computer engineering department working on the chip.

The Wi-Fi radio on the chip is said to use far less power compared with the popular commercial WiFi radios, hence Wi-Fi compatible devices can last for years instead of just hours, even when unplugged. This definitely beats the popular commercial WiFi devices as they will need either large batteries or other external power sources to run for as long as the current chips as it takes 100s of milliwatts just to pair devices.

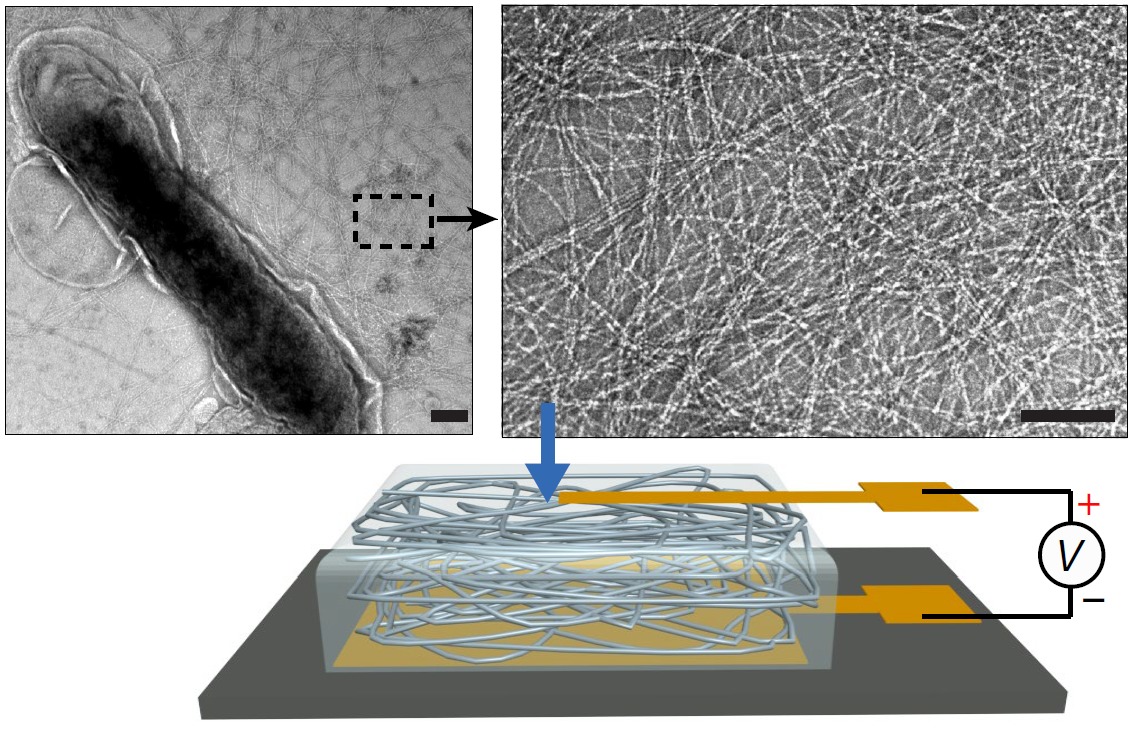

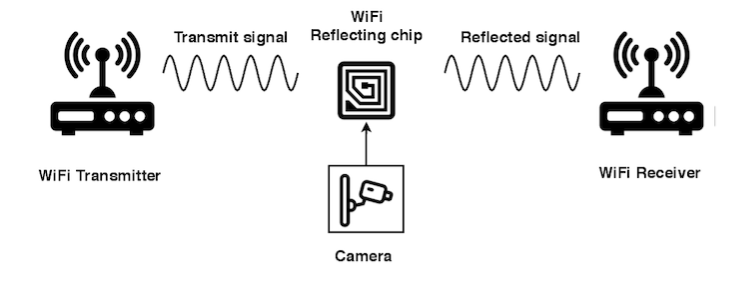

Data transmission by the device is done by taking incoming Wi-Fi signals from a nearby device, modify and encode its own data onto them, and then reflect the new signals onto a different Wi-Fi channel to another device. This process in technical terms is known as backscattering and it simply implies transmitting data by piggybacking data using signals of already connected devices. This feature allows the chip to, not only save on power, but also increases it’s range as it spreads as the WiFi signal continues to spread.

“This WiFi radio uses low enough power that we can now start thinking about new application spaces where you no longer need to plug IoT devices into the wall. This could unleash smaller, fully wireless IoT setups. It could also allow you to connect devices that are not currently connected – things that cannot meet the power demands of current Wi-Fi radios, like a smoke alarm – and not have a huge burden on battery replacement” said Patrick Mercier, another computer and electrical engineering professor who co-led the work with Bharadia.

This team’s improvement to technology is nothing short of interesting as it makes the whole system smaller and more efficient, who knows what the next big thing from them would be.