PWM Halogen Lamp Dimmer

- Rajkumar Sharma

- 22.220 Views

- moderate

- Tested

- SKU: EL46448

- Quote Now

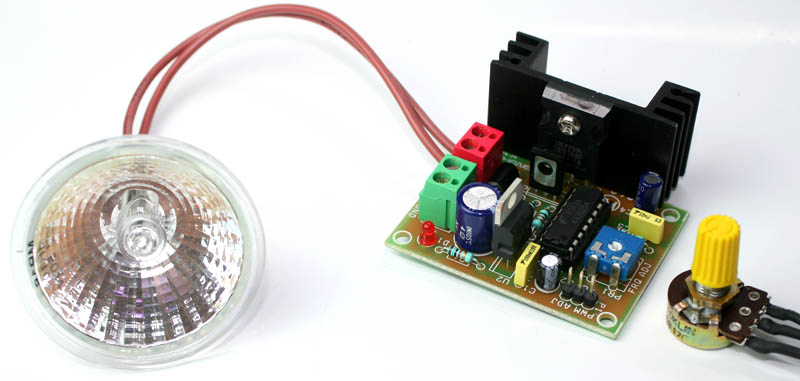

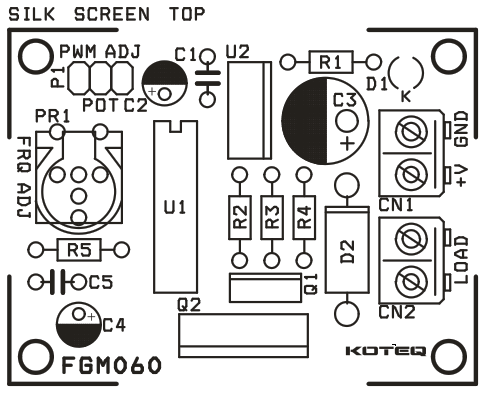

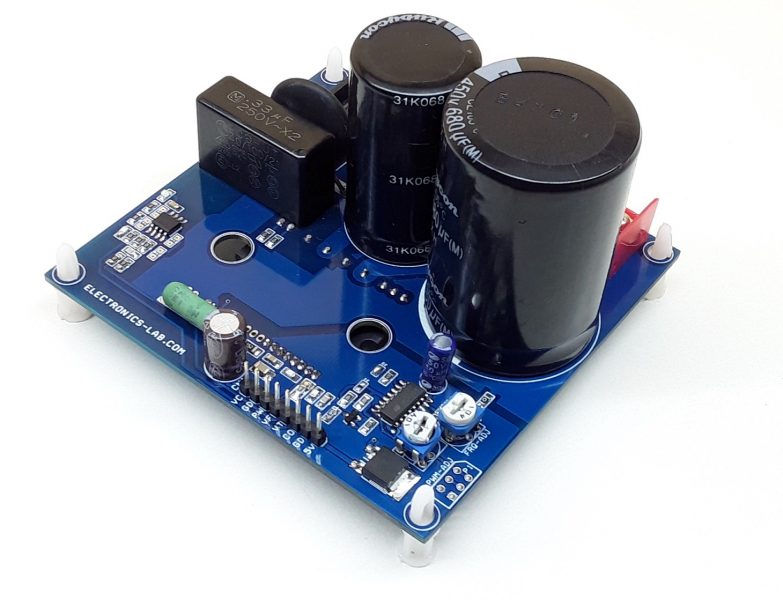

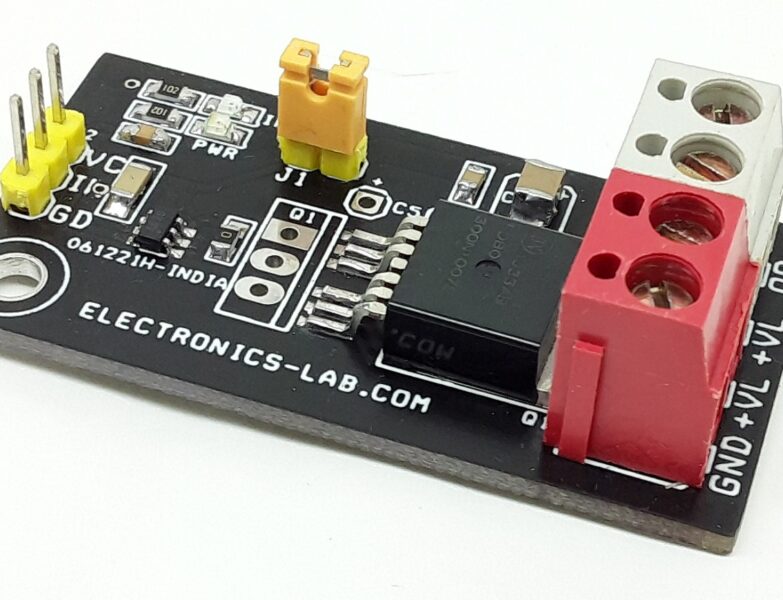

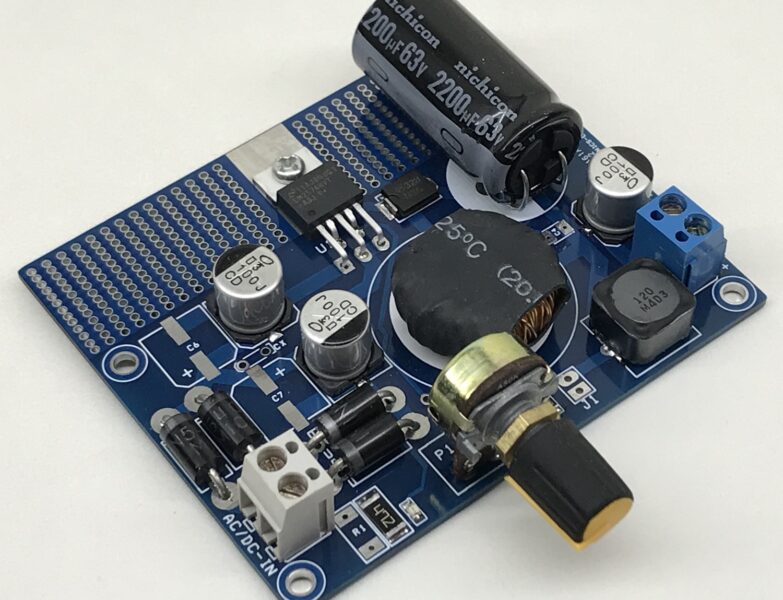

High Current PWM Halogen Dimmer controller project is designed around SG3525 IC and High current MOSFET. Project can handle lamp up to 5 Amps (10Amps Possible with big heat sink) and supply 12-24V DC .Ideal for Halogen Dichroic Lamp or Halogen Lamp.

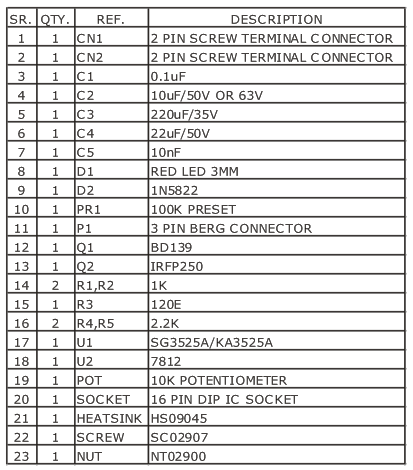

Specifications

- Supply input 15 to 24 VDC

- Load-Lamp 12 to 24 VDC @ 5 Amps (10amps possible with big heat sink on Mosfet)

- Onboard preset for frequency adjust

- Frequency adjustable 4 KHz to 30 KHz

- PWM Duty cycle 0 to 100% (+/- 5%)

- Potentiometer for dimming adjust

- Soft Start facility

- Clamp diode for protection

- Power-On LED indicator

- Compact design and high quality

- Lamp and supply connection via screw terminal connector

- Four mounting holes of 3.2 mm each

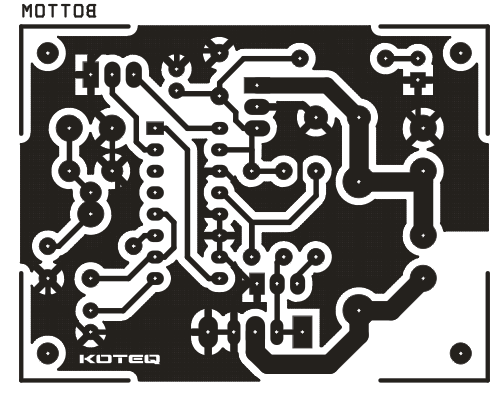

- PCB dimensions 56 mm x 42 mm

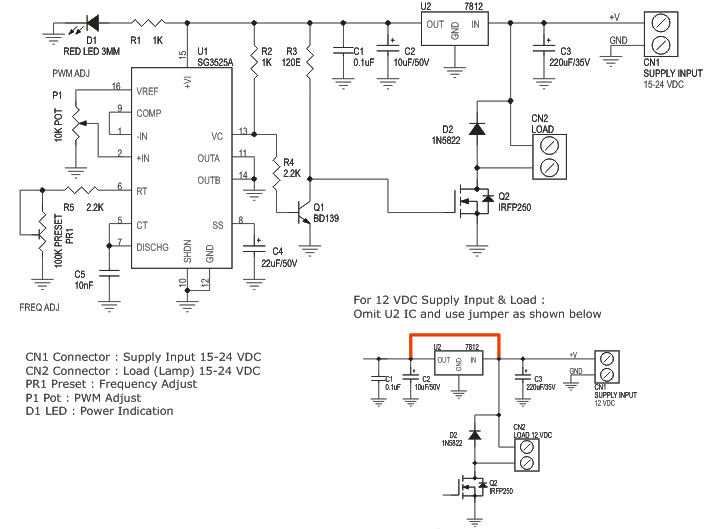

Schematic

IRFP250 is not the best choice for switching 12v (24V) resistive load because of its 90mR on resistance. Also the switching frequency is rather high for PWMing low voltage halogen lap. Some 100Hz is sufficient because of the high thermal mass of the filament and it will reduce switching losses in the MOSFET. Because of the thermal mass, the soft-start function seems to be of little use too.

The idea of grounding both outputs and taking the MOSFET driving voltage from the supply of both totem poles seems rather novel to me. I still do not know if I like it or not 🙂 Nevertheless, a simple 555 timer in PWM mode will provide the same user experience with better gate driving circuit.

hi sir …..sir plz tell me that how can i generate pwm of 20KHZ* from ka3525….sir plz plz give the circuit as 20khz is using in my project….

my email id is ..i am waiting of ur kind reply..

Quartz Halogen lamps **are designed to operate HOT, to make the iodine-gas within prevent the vaporized tungsten ( filament ) atoms from sticking to the inside of the hot quartz tube**

Dimming a Quartz Halogen lamp *will deposit the vaporized tungsten from the filament onto the inside of the tube, instead of having it re-attach to the filament, thereby making the tube opaque AND thinning the filament*

IOW, this is a nice theory, but, given how the actual technology works, it is a Bad Idea(tm).

Quartz Halogen is good for true full-spectrum light, it is ideal for producing *healthy* light, it can provide UV, unless it has a cover-glass which prevents that ( quartz is UV transparent ), .. but it *isn’t* for dimming.

Please use LEDs for that dimming!

: )

Salut, Namaste, & Kaizen.

( :