Smart Soldering Iron Controller – Precision Heater Controller

- Rajkumar Sharma

- 14 Views

- medium

- Tested

- SKU: EL156673

- Quote Now

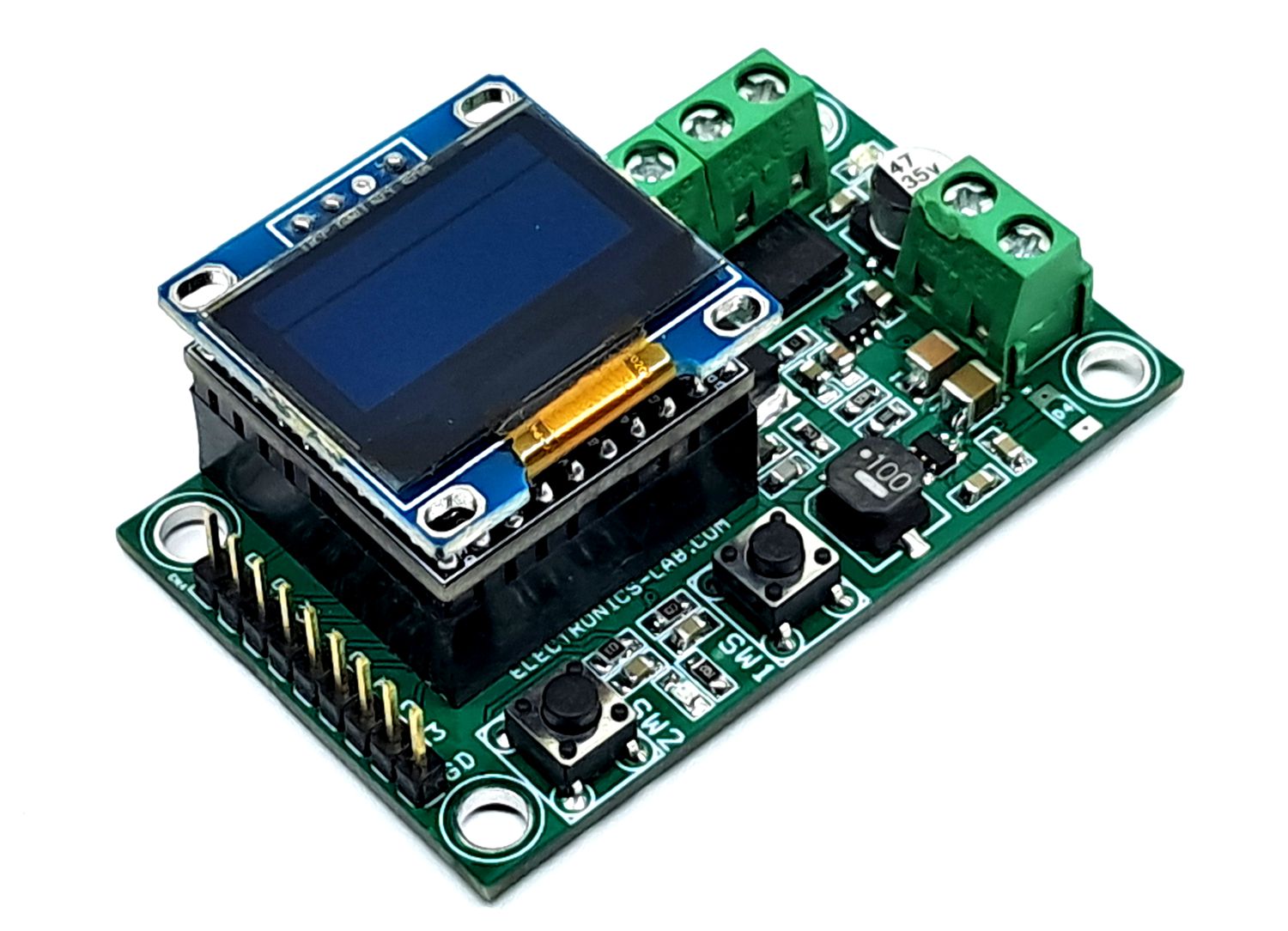

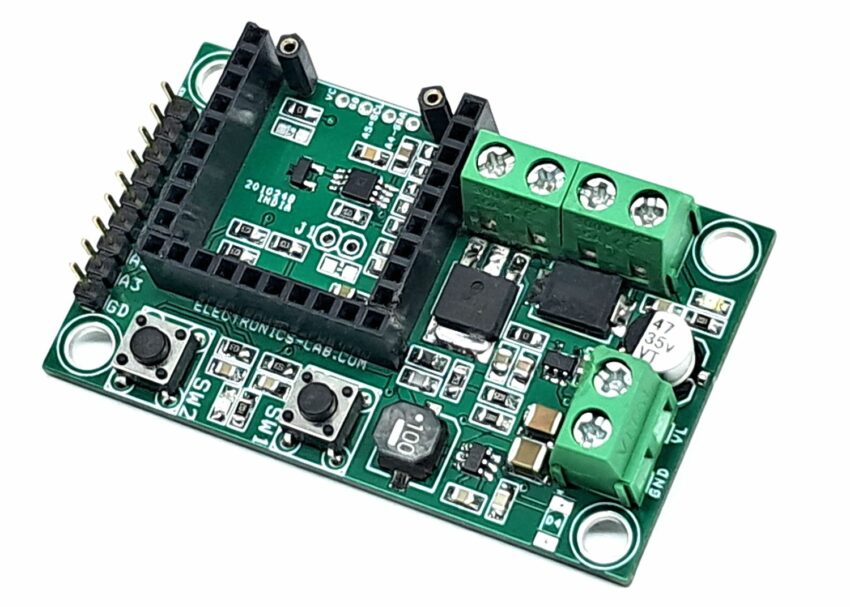

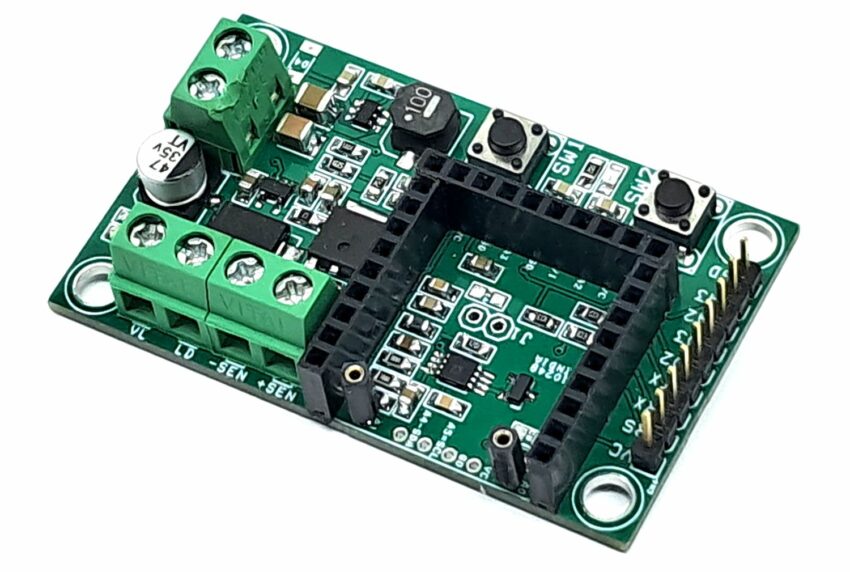

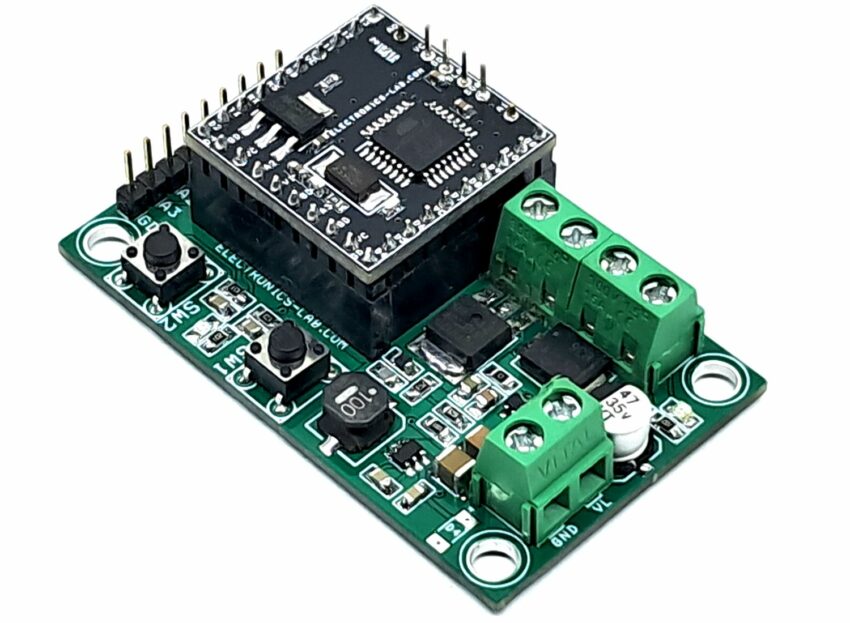

This smart soldering iron controller is a sophisticated system that provides precise temperature control and real-time temperature monitoring. This innovative solution ensures that the temperature at the tip of the soldering iron is consistently maintained, allowing for precise and reliable soldering. Arduino example code is provided below.

Features

- Power Supply 24V DC (Range 13V to 24V DC)

- Load 3A

- AD8495 Output 1.3V to 4.5V

- On Board OLEDDUINO

- On Board, DC-DC Converter Provides 12V DC

- On Board Output LED

- On Board Power LED

- Screw Terminals for Power, Sensor and Low

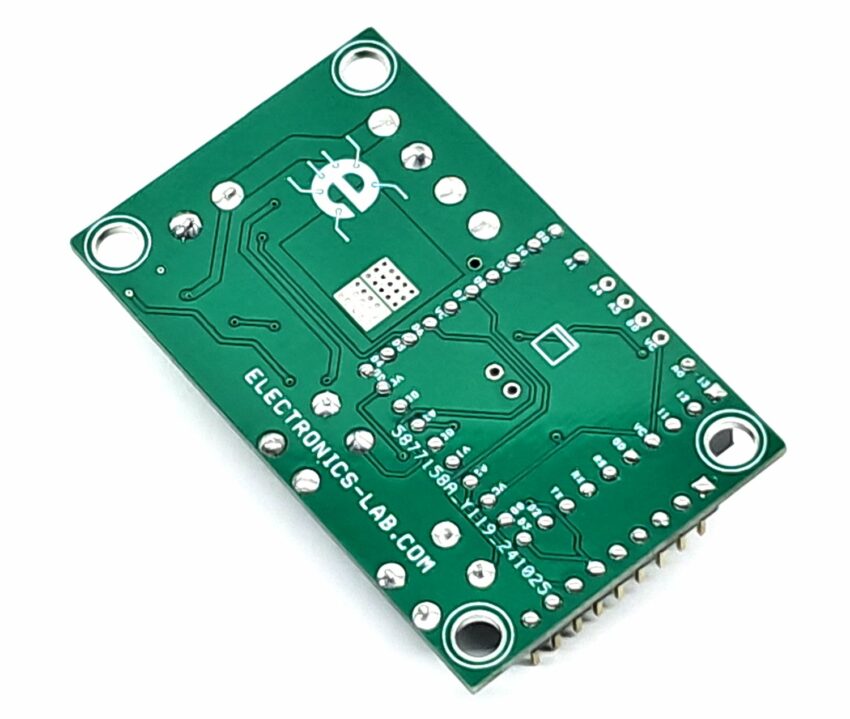

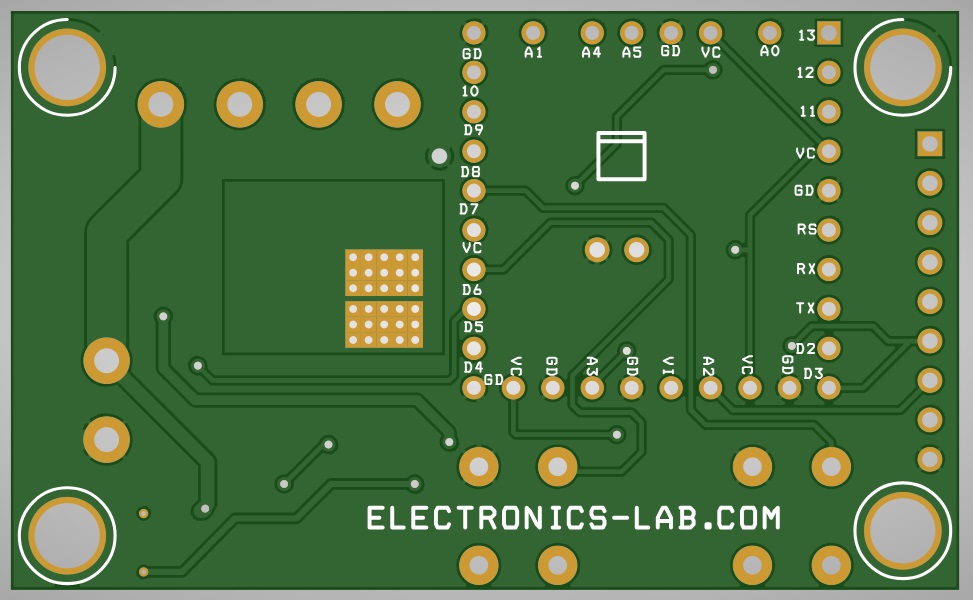

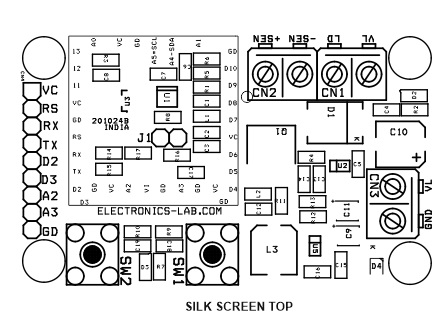

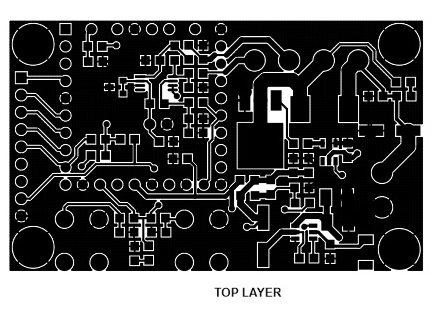

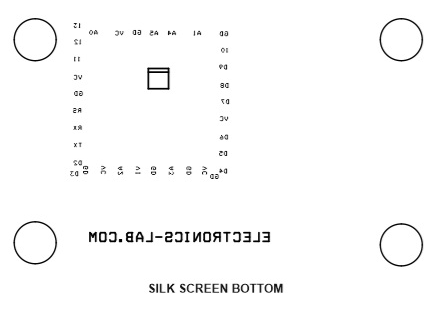

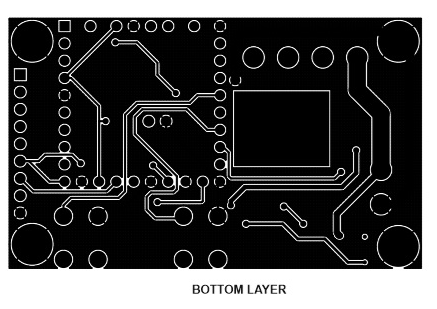

- PCB Dimensions 61.12 x 37.3 1mm

- 4 x 4mm Mounting Holes

Benefits

The smart soldering iron controller offers several benefits, including:

- Precise temperature control, ensuring consistent and reliable soldering results

- Real-time temperature monitoring, allowing for instant adjustments and feedback

- Compact and portable design, making it easy to use in a variety of settings

- High-power handling, suitable for demanding soldering applications

Overall, the smart soldering iron controller is an ideal solution for anyone requiring precise temperature control and real-time monitoring in their soldering applications.

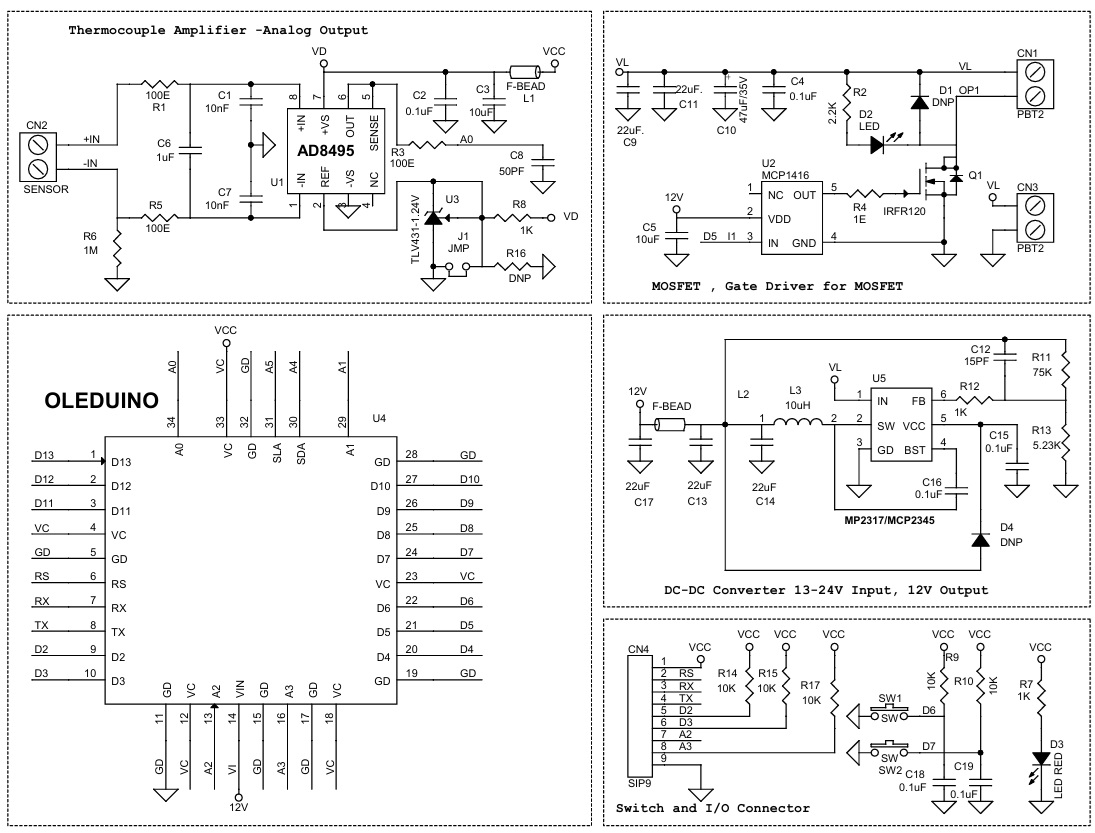

Temperature Sensing

The AD8495 thermocouple amplifier provides high-precision temperature measurement, ensuring accurate readings for the soldering iron tip. At room temperature, the output voltage is 1.3V, and it can range from 1.3V to 4.5V. This amplifier measures the temperature across the thermocouple and provides an analog voltage output, which is then measured and processed by the OLEDUINO.

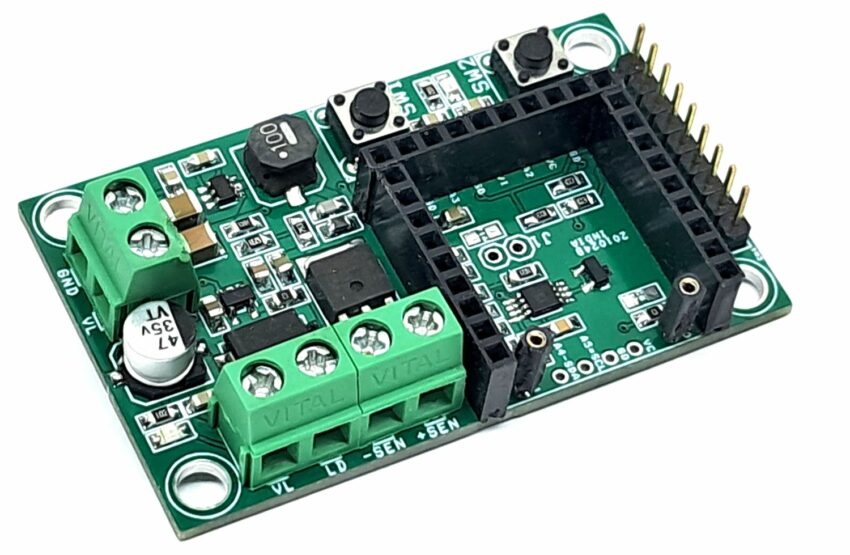

Heating Control

The MOSFET and gate driver enable efficient heating control. The OLEDUINO can generate a PWM (Pulse Width Modulation) signal to drive the MOSFET, allowing for precise heating control. The output load control system supports a duty cycle of 0 to 100% and a PWM frequency of up to 20kHz.

PID (Proportional-Integral-Derivative) Control

For advanced temperature control, a PID algorithm can be implemented in the Arduino code. A PID library is available on GitHub, allowing for precise temperature control and stability.

OLED Display

The OLED display can be used to show real-time temperature readings, warnings, errors, and temperature setup information. This provides a convenient and user-friendly interface for monitoring and adjusting the soldering iron’s temperature.

Switches (SW1 and SW2)

Two tactile switches, SW1 and SW2, can be used for menu control, temperature adjustment, and on/off functionality. Both switches have pull-up resistors, with Switch 1 connected to digital pin 6 (D6) and Switch 2 connected to digital pin 7 (D7).

Applications

The multipurpose hardware can be utilized in a variety of applications, including:

- Precision Temperature Controlled Soldering Iron: The hardware can be used to create a high-precision soldering iron with accurate temperature control, making it ideal for delicate electronics and sensitive components.

- Precision Temperature Controlled Low Voltage Heater: The hardware can be used to control a low-voltage heater with precise temperature control, making it suitable for applications such as warming samples, heating small enclosures, or providing a stable temperature environment.

- Temperature-Controlled Fan Speed: The hardware can be used to control fan speed based on temperature, allowing for efficient cooling and noise reduction in various applications, such as computers, servers, or other electronic devices.

- DC Motor Speed Controller: The hardware can be used as a DC motor speed controller, providing precise control over motor speed and making it suitable for applications such as robotics, drones, or other motorized devices.

These applications demonstrate the versatility and adaptability of the multipurpose hardware, making it a valuable tool for a wide range of projects and applications.

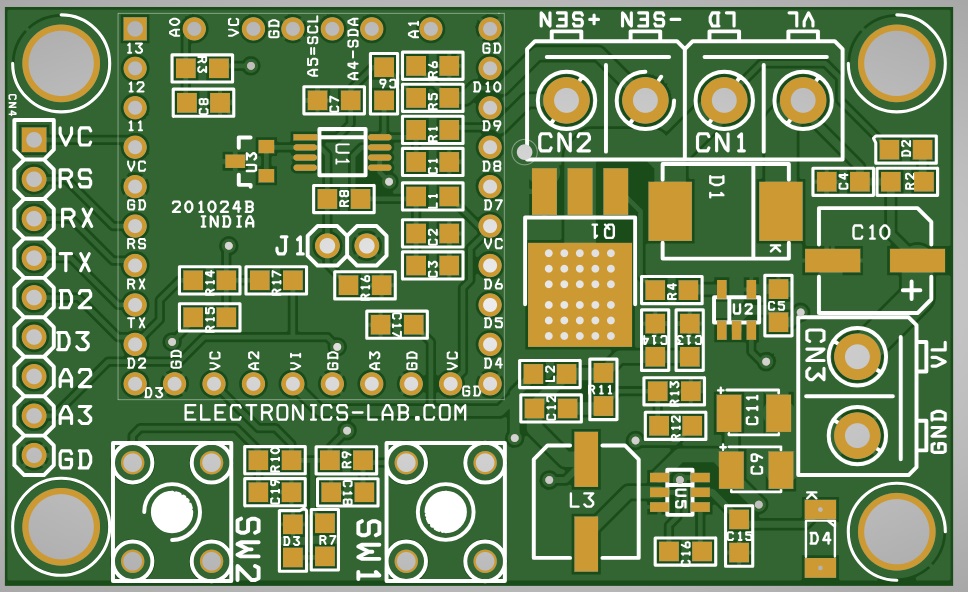

Hardware

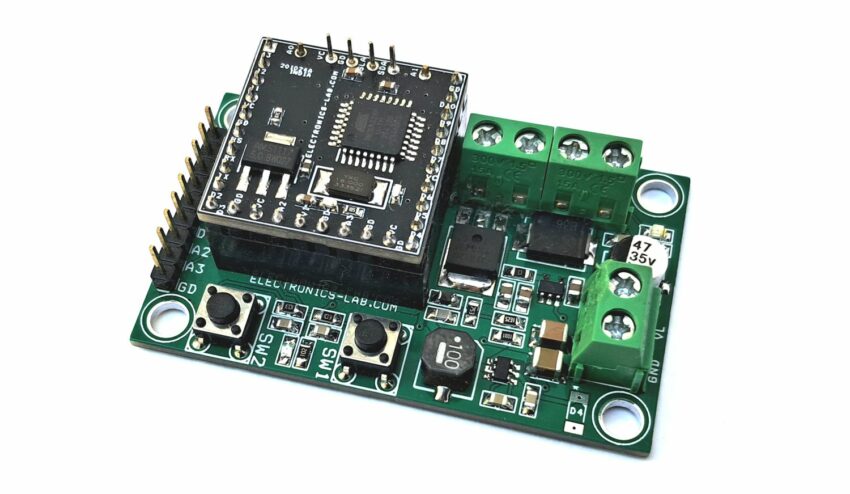

- OLEDDUINO, Temperature Display, Menu Display, on board ATMEGA328 Arduino microcontroller to process the data.

- Precision Thermal Amplifier, Sense the temperature of Heating element and provides analog voltage connected to A0 of OLEDUINO

- MOSFET and MOSFET gate driver, helps driving load such as heating elements, heater, motor

- DC-DC Converter, provides 12V to gate driver and OLEDUINO

- AD8495 thermocouple amplifier provides an analog voltage, enabling precise temperature measurement

- ATmega328 OLDUINO microcontroller reads the analog signal and controls the output MOSFET

- OLED display for menu and temperature display

- MOSFET and gate driver for load current control with PWM signal

- Additional connector with 3 I/O pins (D2, D3, A3) for connecting an external rotary encoder, providing extra control of the menu or other functions

- Connector with Rx, Tx, and Reset pins for Arduino programming or serial read/control

- Screw terminals for easy connection of thermal sensor, power, and load

- Optional diode D1 for use with inductive loads

Inductive Load

This hardware also can control inductive load such as dc motors, and solenoids, advisable to install freewheeling diode D1, MBRS360, or equivalent.

Components

- U1 AD8495 Thermal Amplifier

- U2 MCP1416 MOSFET Gate driver

- U3 TLV431-1.2V Precession Reference Voltage, provides precision reference to AD8495

- U4 OLEDUINO (Link), Consist Arduino Micro-Controller ATMEGA328, OLED Display and 5V Regulator

- U5 MCP2317 DC-DC Converter, 24V to 12V Converter

Arduino Code

Arduino Code is available as a download, this code will help you to test the hardware, this code systems measure the temperature sensor and proportionally provides PWM signal (Sensor analog output range 280 to 1023 Vs PWM 0 to 100% dutycy7cle. The code is certainly not for solder control. Users can write their code as per application requirements.

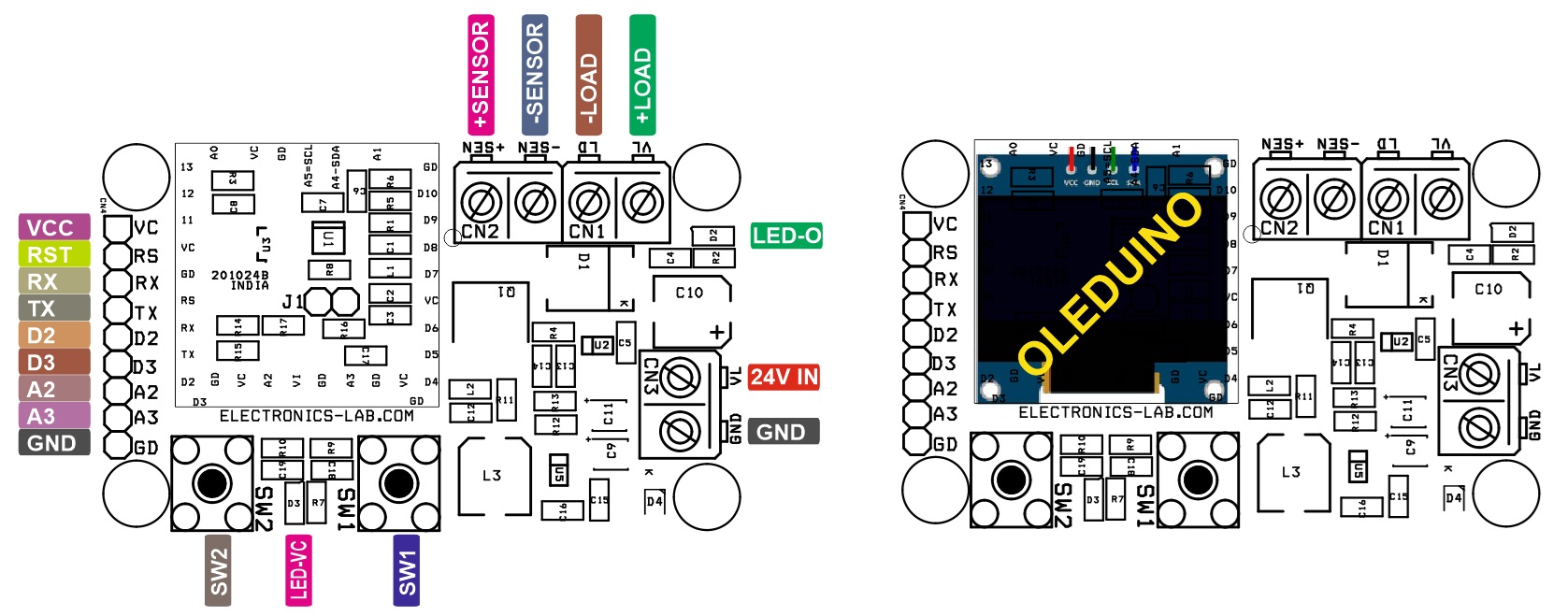

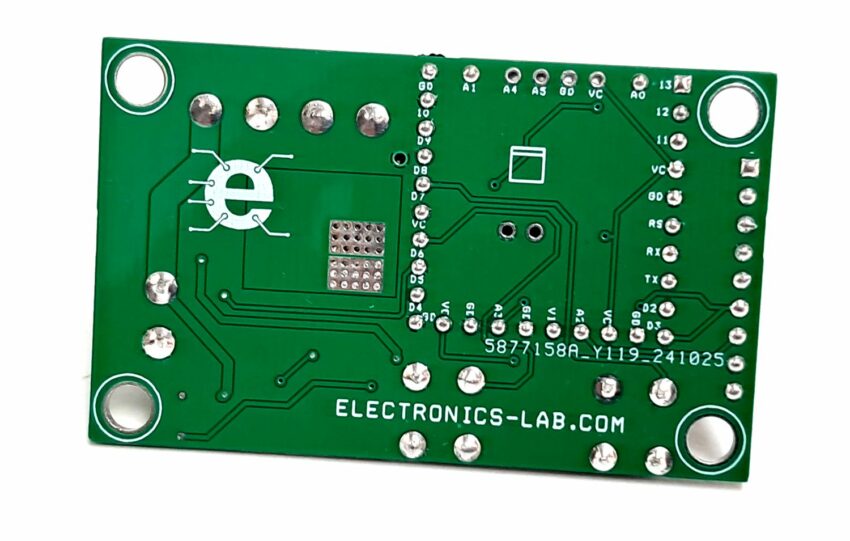

Connections

- CN1 Load- Heating Element: Pin 1 = +Load, Pin 1 (OP1) – Load

- CN2 K-Type Thermal Sensor: Pin 1 Sensor 1, Pin 2 Sensor 2

- CN3 Power Input 24V DC (Range 13V to 24V DC): Pin 1 = +24V DC, Pin 2 = GND

- CN4 Multipurpose I/O: Pin 1 = VCC, Pin 2 = Reset, Pin 3 = RX, Pin 4 = TX, Pin 5 = D2 with Pull Up, Pin 6 = D3 with Pull Up,

- Pin 7 = A2 Analog Input, Pin 8 = A3 with Pull Up, Pin 9 = GND

- D3: Power LED

- D1: Load/Output LED

- SW1 Tactile Switch: Function Control Such as Menu (D6 with Pull-Ups)

- SW1 Tactile Switch: Function Control Such as Menu (D7 with Pull-Ups)

Schematic

Parts List

| NO. | QNTY. | REF | DESC. | MANUFACTURER | SUPPLIER | SUPPLIER PART NO |

|---|---|---|---|---|---|---|

| 1 | 3 | CN1,CN2,CN3 | 2 PIN SCREW TERMINAL PITCH 5.08MM | PHOENIX | DIGIKEY | 277-1247-ND |

| 2 | 1 | CN4 | 9 PIN MALE HEADER PITCH 2.54MM | WURTH | DIGIKEY | 732-5322-ND |

| 3 | 2 | C1,C7 | 10nF/50V CERAMIC SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 4 | 2 | C3,C5 | 10uF/35V CERAMIC SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 5 | 6 | C2,C4,C15,C16,C18,C19 | 0.1uF/50V CERAMIC SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 6 | 1 | C6 | 1uF/25V CERAMIC SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 7 | 1 | C8 | 50PF/25V CERAMIC SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 8 | 2 | C9,C11 | 22uF/35V CERAMIC SMD SIZE 1210 | YAGEO/MURATA | DIGIKEY | |

| 9 | 1 | C10 | 100uF/35 OR 47uF/35V ELEKTROLYTIC 6.6MM | WURTH | DIGIKEY | 732-8511-1-ND |

| 10 | 1 | C12 | 15PF/50V CERAMIC SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 11 | 3 | C13,C14,C17 | 22uF/16V CERAMIC SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 12 | 2 | D2,D3 | LED RED SMD SIZE 0805 | OSRAM | DIGIKEY | 475-1278-1-ND |

| 13 | 4 | D4,R16,D1,J1 | DNP | |||

| 14 | 2 | L1,L2 | FERRITE BEAD 600OHMS 1.5A SIZE 0805 | LAIRD | DIGIKEY | 240-2390-1-ND |

| 15 | 1 | L3 | 10uH/3A 6.6X6.6MM | TDK | DIGIKEY | 445-180838-1-ND |

| 16 | 1 | Q1 | IRFR120NTRPBF 9.4A/100V | INFINEON | DIGIKEY | IRFR120NPBFCT-ND |

| 17 | 3 | R1,R3,R5 | 100E 5% SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 18 | 1 | R2 | 2.2K 5% SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 19 | 1 | R4 | 1E 5% SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 20 | 1 | R6 | 1M 5% SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 21 | 3 | R7,R8,R12 | 1K 5% SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 22 | 5 | R9,R10,R14,R15,R17 | 10K 5% SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 23 | 1 | R11 | 75K 1% SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 24 | 1 | R13 | 5.23K 1% SMD SIZE 0805 | YAGEO/MURATA | DIGIKEY | |

| 25 | 2 | SW1,SW2 | TACTILE SWITCH 4 PIN | C&K | DIGIKEY | CKN9085CT-ND |

| 26 | 1 | U1 | AD8495 | ANALOG | DIGIKEY | AD8495CRMZ-R7CT-ND |

| 27 | 1 | U2 | MCP1416 | MICROCHIP | DIGIKEY | MCP1416T-E/OTCT-ND |

| 28 | 1 | U3 | TLV431 1.24V | TI | DIGIKEY | TLV431AFTACT-ND |

| 29 | 1 | U4 | OLEDUINO | ELECTRONICS-LAB | DIGIKEY | |

| 30 | 1 | U5 | MP2317 (MCP2345) | MPS | DIGIKEY | 1589-1580-1-ND |

Connections