Prosthetics Feeling Is Now Possible With This Implantable Chip By Imec

Imec, the world-leading research and innovation hub in nano-electronics and digital technology, announced last month its prototype implantable chip that aims to give patients more intuitive control over their arm prosthetics. The thin-silicon chip is said to be world’s first for electrode density. Creating a closed-loop system for future-generation haptic prosthetics technology is the aim of researchers.

What is special about this chip?

The already available prosthestics are efficient and have their own key features; like giving amputees the ability to move their artificial arm and hand to grasp and manipulate objects. This is done by reading out signals from the person’s muscles or peripheral nerves to control electromotors in the prosthesis. Good news is that revolutionary features are coming! The future prosthetics will provide amputees with rich sensory content. This can be done by delivering precise electrical patterns to the person’s peripheral nerves using implanted electrode interfaces.

The goal behind working on this new technique is to create a new peripheral nerve interfaces with greater channel count, electrode density, and information stability according to Rizwan Bashirullah, director of the University of Florida’s IMPRESS program (Implantable Multimodal Peripheral Recording and Stimulation System)

Fabricated amazingly in a small scale!

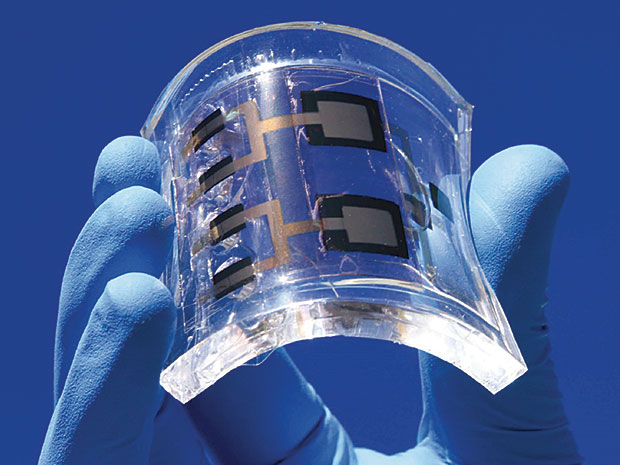

A prototype of ultrathin (35µm) chip with a biocompatible, hermetic and flexible packaging is now available. On its surface are 64 electrodes, with a possible extension to 128. This large amount of electrodes is used for fine-grained stimulation and recording. As the short video shows, the researchers will insert the package and attach it to a nerve bundle using an attached needle which will give better results compared to other solutions usually wrapped around nerve bundles.

“Our expertise in silicon neuro-interfaces made imec a natural fit for this project, where we have reached an important milestone for future-generation haptic prosthetics,” commented Dries Braeken, R&D manager and project manager of IMPRESS at imec. “These interfaces allow a much higher density of electrodes and greater flexibility in recording and stimulating than any other technology. With the completion of this prototype and the first phase of the project, we look forward to the next phase where we will make the prototype ready for long-term implanted testing.”

The Defense Advanced Research Projects Agency’s (DARPA) Biological Technologies Office sponserd this work of University of Florida researchers under the auspices of Dr. Doug Weber through the Space and Naval Warfare Systems Center. For more details about this topic check this article.