New modulation method increases operational lifetime of switching power units through digital, highly dynamic control and the use of film capacitors.

Switching power units are used for the power supply of many electrical devices, e.g. computers, LED lights or laser welding equipment. They convert alternating current from the mains into the direct current required by the device. A frequent cause of failure of technical devices is the failure of the integrated power supply units. These thus limit the service live of the devices or require more frequent service intervals.

The electrolytic capacitors used in the power unit are particularly susceptible to faults. They buffer electrical energy and smooth voltage fluctuations over a mains period. Electrolytic capacitors offer a high energy density and are mostly regulated analogously. Film capacitors, on the other hand, would be much more durable. However, due to their lower energy density, these require ten times the installation space for the same capacity.

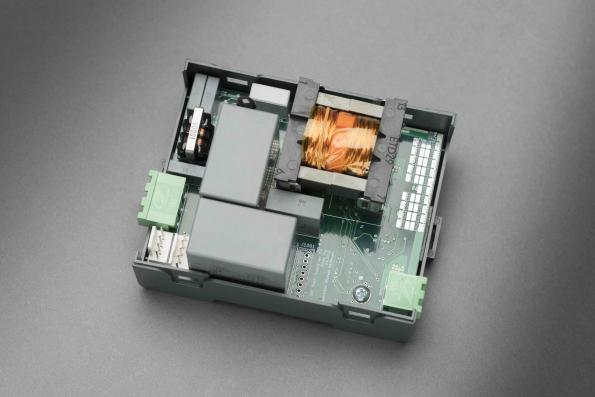

Scientists at the Light Technology Institute (LTI) at KIT have developed a new modulation process for the digital and highly dynamic control of power supply units that enables the use of film capacitors with only little increased installation space. For the first time, the method allows the output current to be controlled taking into account the DC link voltage and output voltage, whereby frequency and duty factor are possible control variables. The inclusion of these variables makes the control more robust, safer and faster. Input and output voltages are also considered, which improves control inaccuracies.

As a result of the longer operational lifetime of the film capacitors used, the failure rate of the switching power units can be reduced and thus the durability of the terminal devices can be increased many times over. Reduced maintenance effort is particularly useful in places that are difficult to access or with high-quality devices, e.g. electric cars. Due to the accuracy and flexibility of the highly dynamic control, power supply units of this type are particularly advantageous for industrial applications with high dynamic requirements. In addition, Internet of Things integration for remote diagnosis or remote maintenance is also possible without any problems.

A functional prototype was set up at the institute and measurement results, including lifetime measurements, are available. KIT is looking for industrial partners to develop application-specific, high-quality power supplies in the premium segment.

Further information: https://www.kit-technology.de/en/technology-proposals/details/664/