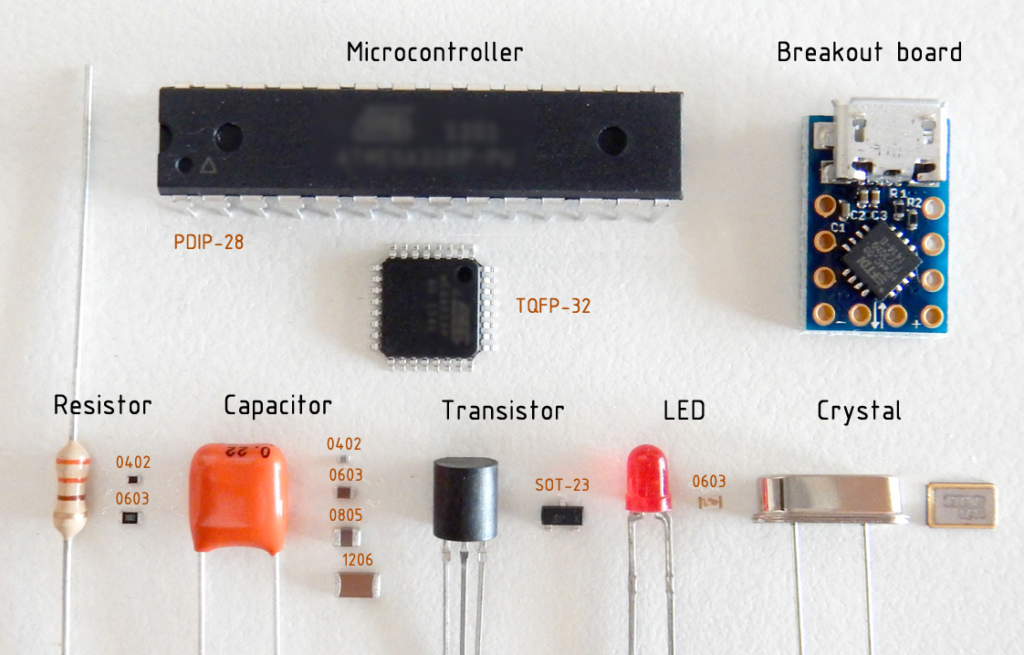

In this article Vassilis K. Papanikolaou explains how SMD prototyping practice can be used in learning environments using simple and wide available tools and equipment:

A feasibility study is herein attempted, towards the adaptation of modern surface-mount device (SMD) prototyping practice to learning environments. This necessity emerges not only from the profound advantages of the above technology (e.g. component size, availability, low cost etc.) but also from the fact that contemporary designs often require special board layout considerations, which may be incompatible with through-hole components. In addition, the long process between prototyping and product finalization can be greatly shortened. Nevertheless, the employment of surface-mount techniques in education may be discouraged by both the unappealing part sizes (i.e. handling difficulty) and the excessive cost of commercial supporting equipment. The main objective of this study is to suggest practical and low-cost solutions for all different SMD prototyping/manufacturing stages, which can demystify and render this procedure welcome and easily applicable in laboratory classes.

Surface-mount device prototyping in education – [Link]