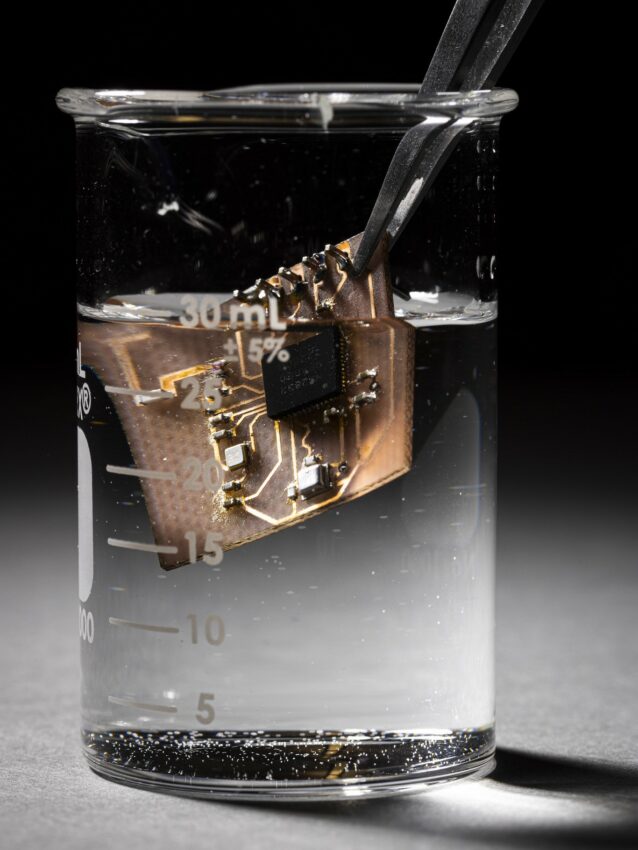

Researchers at the University of Washington (UW) have created A new kind of PCB what they are calling a “Vitrimers PCB” or vPCB for short. The unique characteristic of this PCB is that it’s made to be recycled. In the lab, scientists manufactured functional prototypes of Internet of Things (IoT) devices transmitting 2.4 GHz radio signals on vPCBs then they recycled that PCB and recovered 98% of the vitrimer and 100% of the glass fiber, as well as 91% of the solvent used for recycling.

The UW team also tested the Vitrimer PCB for its electrical, thermal, and mechanical properties and found that they are very similar to standard FR-4 PCB material. This suggests that Vitrimer PCBs could offer a viable solution to reduce landfill waste by facilitating the recycling of leftover copper, thereby maximizing resource recovery.

Vitrimers are a new class of plastics that are both strong and reprocessable. Unlike traditional thermosets, which are permanently hardened after being formed, vitrimers can be reshaped and recycled multiple times without losing their properties. This is because vitrimers have dynamic chemical bonds that can be broken and reformed with the application of heat, enabling them to be molded like glass. This unique ability makes vitrimers promising for a variety of applications where durability and sustainability are important.

A solvent dissolves the vitrimer in vPCBs, separating it into a jelly-like substance for easy recovery of glass fibers and metal traces. Researchers were able to recover 98% of the vitrimer, 100% of the glass fiber, and 91% of the solvent. This recycling process could reduce the global warming potential by 48% and carcinogenic emissions by 81% compared to traditional PCBs.

While the new Vitrimers PCB appears to be a promising green solution, its real-world adoption depends on a few factors: it needs to be affordable to produce, there should be incentives in place to encourage the recycling of electronic waste, and more research is needed to ensure it can perform well in high-speed and demanding applications.

Key Features of Vitrimers-based Recyclable PCB:

- Utilizes vitrimer epoxy, a polymer capable of repeated curing and uncuring without deterioration.

- Environmentally conscious design aimed at reducing electronic waste and promoting a circular lifecycle for electronics.

- Maintains electrical and mechanical performance similar to commonly used FR-4 PCB materials.

- Recyclability features include repairability under heat and pressure, easy removal of components for reuse or responsible recycling, and the ability to recover and reuse base vitrimer and glass fibers in new PCBs.

- Demonstrates high recovery rates for vitrimer, glass fiber, and solvent used in the manufacturing process.

- Compatible with existing PCB manufacturing processes, requiring minimal adjustments.

More information on this Vermiters-based recyclable PCB can be found on the UW news page. The researchers mention that further research is ongoing to develop even better vitrimer materials for a wider range of applications.